Description

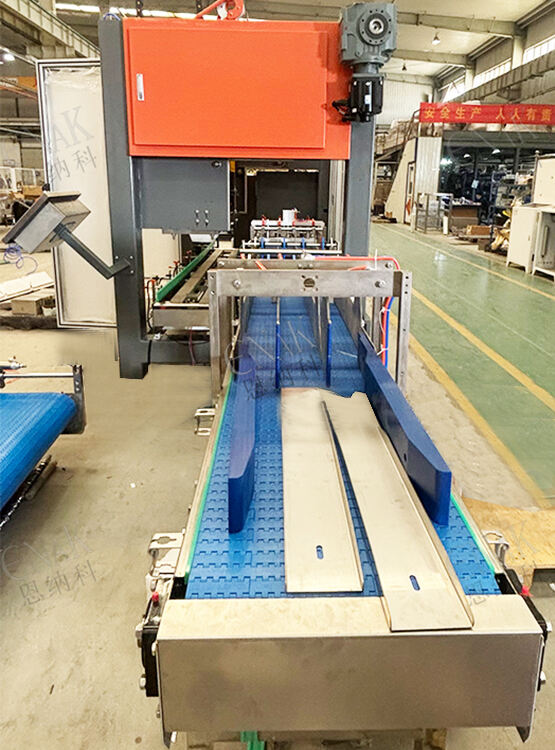

The Metal Can Canned Food Case Packer Machine, developed by ENAK (Tianjin) Automation Equipment Co., Ltd., is a highly efficient automatic case packing machine designed for various packaging types. This machine is suitable for PE bottles, glass bottles, small cartons, paper boxes, and metal cans, delivering fast, neat, and clean case packing operations. It offers simple operation with stable, efficient production lines and aesthetically pleasing packaging output.

Production Capacity: Packs 12 to 40 cases per minute, meeting medium to high production demands.

Bottle Handling Length: Standard 2000 mm, customizable based on client site conditions.

Bottle Size Adaptability: Diameter 55-130 mm, height 140-335 mm.

Carton Size Adaptability: Length up to 400 mm, width 350 mm, height 350 mm, covering various carton specifications.

Power Supply: Three-phase, 380V, 50Hz; customizable based on requirements.

Power Consumption: 5 kW, energy efficient.

Compressed Air Requirement: 0.8-1 cubic meters/minute at 6 bar pressure.

Machine Dimensions: Length 6700 mm, width 2140 mm, height 3010 mm.

Machine Weight: Approximately 2000 kg, stable and durable.

Gripper Quantity: Customizable to meet different packaging needs.

| Parameter Item | Parameter Value |

| Production Capacity | 12 - 40 cases/minute |

| Bottle Handling System | 2000 mm (Customizable according to customer site) |

| Bottle Dimensions | Diameter (55-130) * Height (140-335) mm |

| Carton Dimensions | Length (50-400) * Width (50-350) * Height (50-350) mm |

| Power Supply | 3-Phase; 380V; 50Hz (or customized as required) |

| Power Consumption | 5 kW |

| Number of Gripping Heads | Customized |

| Compressed Air | 0.8 - 1 m鲁/min (Pressure: 6 bar / 0.6 MPa) |

| Overall Dimensions | Length 6700 * Width 2140 * Height 3010 mm |

| Equipment Weight | 2000 kg |

Product Advantages

Automatic Fault Detection and Alarm System:

Equipped with an advanced automatic fault detection and alarm system, this machine continuously monitors its operational status. Upon detecting abnormalities such as material shortage, bottle jamming, or mechanical failures, the system immediately triggers audible and visual alarms to notify operators. This greatly reduces downtime caused by malfunctions, ensures smooth and stable production, lowers labor monitoring costs, and enhances overall safety and reliability.

Durable Transmission Structure with Long Service Life:

Core transmission components are made from high-strength alloy steel, undergoing precision machining and heat treatment for smooth operation and excellent wear resistance. The scientifically designed transmission system ensures high power transmission efficiency and is supported by a quality lubrication system, significantly prolonging machine service life. This structure supports stable operation under heavy-load conditions while minimizing maintenance frequency and replacement costs.

High-Strength Frame with Excellent Vibration Resistance:

The equipment frame is welded from industrial-grade high-strength steel and treated with multiple anti-corrosion and surface finishing processes, ensuring robust durability. The heavy-duty frame resists vibrations and shocks during production, maintaining machine stability. This vibration resistance not only improves packing precision and product quality but also reduces part wear, guaranteeing long-lasting, stable performance even in demanding manufacturing environments

Manufacturing Process

High-Precision Frame Fabrication:

The frame is made of industrial-grade high-strength steel, precisely cut by advanced CNC machines to ensure accurate dimensions. Professional welding guarantees strong and stable structural integrity to support long-term heavy-duty use.

Surface Protection Treatment:

All metal components undergo strict sandblasting and rust removal processes, followed by environmentally friendly powder coating or stainless steel polishing to form a dense protective layer, increasing corrosion resistance and aesthetic appeal while meeting strict food industry hygiene standards.

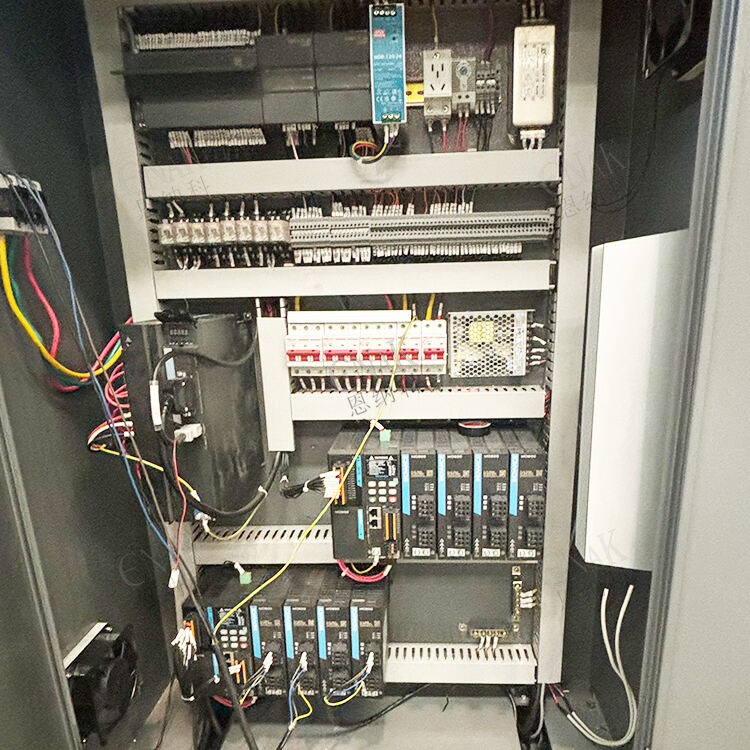

Precision Electrical Component Integration:

Selected premium international brand Schneider electrical parts combined with high-performance servo drive systems realize precise control of all machine motions and stable operation. The electrical system emphasizes safety and reliability and includes multiple protection and alarm functions to ensure smooth production.

Optimized Assembly and Debugging Process:

Assembly follows standardized procedures with multi-stage inspections to ensure the coordination of mechanical actions. Customized debugging and parameter tuning for different customers guarantee optimal machine performance. Simulated production tests are conducted to detect and eliminate potential faults early, ensuring efficient and reliable on-site operation.

Modular Design Concept:

The machine employs a modular design, with key functional units independently manufactured and tested for quick assembly and easier maintenance. This modular structure allows flexible expansion and higher customization levels according to client requirements.

Strict Quality Control System:

Throughout the production cycle, multiple quality checks are performed, including raw material inspection, machining accuracy testing, assembly quality verification, and final performance evaluation, ensuring each machine fulfills ENAK’s high-standard quality requirements and delivers reliable products to customers.

Frequently Asked Questions

Q1: What types of packaging bottles does the machine support?

A1: It supports PE bottles, glass bottles, metal cans, and a wide range of sizes.

Q2: What is the production capacity?

A2: The machine can pack 12 to 40 cases per minute, adjustable based on customer requirements.

Q3: How does the machine handle faults?

A3: It is equipped with an automatic fault detection and alarm system that notifies operators immediately and automatically stops operation to facilitate quick troubleshooting and repair.

Q4: Is maintenance difficult?

A4: The machine’s durable materials and rational design make maintenance easy and spare parts readily available.

Please leave your inquiry to receive professional technical support and customized solutions from ENAK (Tianjin) Automation Equipment Co., Ltd.