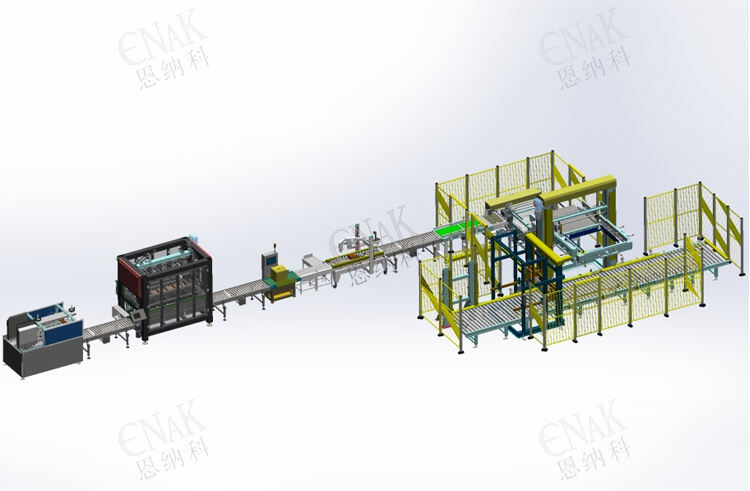

Automatic Gantry Case Palletizer Machine Tray Barrel Case Carton Bag Packing Palletizer ENK-MD40

Description

Product Overview:

The Single Column Automatic Carton Palletizing Equipment (ENK-MD1800-150) developed by ENAK (Tianjin) Automation Equipment Co., Ltd. is a high-efficiency device dedicated to automatic palletizing of carton products. Adopting a single-column structure design, it balances space saving and operational stability, which can replace traditional manual palletizing. It is widely used in food, daily chemical, pharmaceutical, electronics and other industries, helping enterprises connect the "last mile" of packaging automation and improve overall production efficiency.

Product Performance:

The equipment has high palletizing efficiency, capable of completing multiple batches of carton palletizing tasks per hour, and is compatible with a wide range of pallet sizes; it is equipped with a high-precision servo drive system, with fast action response and accurate positioning, and the palletizing error is controlled within a very small range; it has a complete safety protection system, such as safety light curtains and emergency stop buttons, to ensure the safety of operators; it supports 24-hour continuous operation with low failure rate, and can stably match the needs of high-rhythm production lines.

| Parameter | Value |

| Model | ENK - MD40 |

| Minimum Order Quantity | 1 |

| Price Step (USD) | 25000 |

| Unit | Set |

| Overall Dimensions | 1250X200X200 |

| Gross Weight (KG) | 7500 |

| Shipment Quantity | 1 |

| Estimated Shipment Time | 35 |

| Packaging Method | Wooden Case |

| Service | Free Replacement of Parts |

| Power | 15KW |

| Voltage | 380V/50HZ |

| Body Material | Carbon Steel Baked Enamel |

| Load (KG) | 260 |

| Working Radius | 1750 |

| Palletizing Speed | 25 - 40 cases/min |

| Applicable Product Types | Carton - type, Film - package type, Large - barrel type |

| Pallet Size (MM) | L800 - 1300W800 - 1200H100 - 150 |

| Gripping Method | Automatic Placement |

| Warranty Period | 3 Years |

| After - sales Service System | Video Technical Support, On - site Guidance, On - site Installation, Commissioning and Training, Online Support, Free Spare Parts |

| Core Components | Bearing, Motor, Pump, Gear, PLC, Pressure Vessel, Engine, Transmission |

Product Advantages

Multiple Gripping Methods:

The palletizer system can flexibly configure end effectors according to different product characteristics, completely breaking the limitation of single gripping. For rigid carton products, it is equipped with high-strength mechanical grippers, which achieve stable gripping through precise pressure control to avoid carton deformation; for bagged products (such as flour bags and feed bags), a combination of vacuum suction cups is used, and the negative pressure adsorption principle is applied to prevent damage and material leakage of bagged materials; for barreled products or fragile items, customized gripper combinations are matched with buffer devices, which can evenly distribute the gripping force to avoid extrusion deformation of barrels or collision damage of fragile items. The rich gripping solutions allow the palletizer system to adapt to various products such as cartons, bags, barrels and fragile items, covering palletizing needs in multiple industries with extremely wide applicability.

Easy Maintenance:

The palletizer system focuses on the demand for "low maintenance" in the design stage. Key components adopt maintenance-free design - for example, core transmission components are made of high-wear-resistant materials with built-in sealed dust-proof structures, which do not require frequent disassembly and maintenance; at the same time, convenient maintenance windows are set at the positions of easily worn parts, and worn parts can be quickly replaced by opening the windows without disassembling the overall structure. The lubrication points of the palletizer system are centrally designed, with unified lubrication interfaces. Daily maintenance only requires regular addition of lubricating oil at the designated interfaces, combined with simple appearance inspection and parameter verification, to ensure stable operation of the equipment. Compared with the complex maintenance process of traditional palletizing equipment, this palletizer system greatly reduces maintenance difficulty and frequency, and maintenance costs are reduced by more than 40%.

Improved Product Quality:

In the traditional manual palletizing process, workers are prone to operational errors due to fatigue from long-term work, resulting in problems such as carton scratches, falls and skewed palletizing, which affect product appearance and packaging integrity. However, this palletizer system realizes fully automated operation. From product gripping, handling to palletizing, the entire process is accurately controlled by programs, with stable movements and uniform force, which can completely avoid the uncertainty of manual operation. Whether it is the protection of carton edges or the neatness of multi-layer palletizing, consistent standards can be maintained to ensure that the product packaging appearance is intact. Stable product quality not only reduces the defective rate, but also enhances consumers' trust in the brand, helping enterprises shape a high-quality brand image.

Operation Guide

Pre-start Preparation:

First, check the equipment appearance to confirm that mechanical components are not loose or damaged, and safety protection devices (such as safety light curtains and emergency stop buttons) are normal; second, verify the stability of power and air source connections, turn on the main power switch and air source valve, and check whether the pressure gauge value is within the standard range (0.6-0.8MPa); finally, check the equipment parameters through the HMI (Human-Machine Interface) to confirm that parameters such as palletizing speed and pallet pattern specifications are consistent with production requirements.

Operation Process:

Click the "Start" button on the HMI interface, and the palletizer system enters the standby state; place the cartons to be palletized on the feeding conveyor line, and the equipment automatically starts the gripping program after sensing the materials, and completes the gripping, handling and palletizing actions according to the preset pallet pattern; during operation, observe the operation status and output data displayed on the HMI interface in real time. If you need to pause, click the "Pause" button, and click "Continue" to resume operation.

Shutdown Operation:

After the completion of the batch palletizing task, click the "Stop" button on the HMI interface. After the palletizer system returns to the initial position, turn off the air source valve to release the residual gas in the pipeline; then turn off the main power switch of the equipment, clean the dust and debris on the equipment surface, record the daily operation data (such as output and operation time), and complete the shutdown process.

Frequently Asked Questions

Q: Can the palletizer system adapt to both cartons and bagged products at the same time? Is frequent part replacement required?

A: Yes, it can. The palletizer system supports quick replacement of end effectors. It only takes 15-20 minutes to replace mechanical grippers and vacuum suction cups, and no professional tools are needed. Ordinary operators can complete the replacement without frequent equipment disassembly, which does not affect the production rhythm.

Q: Does daily maintenance require professional technicians? How often is a comprehensive maintenance carried out?

A: Daily maintenance does not require professional technicians. It can be done by conducting simple inspections and lubrication in accordance with the operation manual; comprehensive maintenance is recommended every 6 months, mainly checking the wear of core components and the connection status of electrical circuits. We will provide maintenance guidance videos and documents.

Q: If a fault occurs during the operation of the palletizer system, how to deal with it quickly?

A: The palletizer system has a fault self-diagnosis function. The HMI interface will display error codes and fault locations. Operators can check the fault manual to find solutions; if it cannot be handled by themselves, you can call the after-sales hotline, and our technicians will quickly solve the problem through remote assistance or on-site service.

If you want to know the quotation, customized solution or on-site demonstration of the ENK-MD1800-150 Single Column Automatic Carton Palletizing Equipment, please leave your name, contact information and enterprise needs. Our sales team will contact you within 24 hours to provide you with exclusive services