Description

The tin can labeling machine automatically applies labels to sealed tinplate cans that enter the equipment in sequence. It works either as a standalone unit or in a production line, with two models for different can sizes: ENKG-01 (small cans) and ENKGD-01 (large cans), both designed for easy packaging and storage.

Technical Specifications

| Category | Item | Specification / Value |

| 1. Environmental Conditions | Altitude | 3 – 2,000 meters above sea level |

| Ambient Temperature | 0℃ – 40℃ | |

| Humidity | 40% – 95% | |

| 2. Equipment Weight | ENKG-01 | 750 kg |

| ENKGD-01 | 900 kg | |

| 3. Label Size Requirements | For ENKG-01 | Maximum: 390 × 254 mm |

| Minimum: 150 × 20 mm | ||

| For ENKGD-01 | Maximum: 500 × 254 mm | |

| Minimum: 214 × 50 mm | ||

| 4. Requirements for Related Materials | Adhesive for Labeling | Hot melt adhesive + quick-drying adhesive |

| Applicable Production Line Height | Inlet: 1,100 – 1,200 mm | |

| Outlet: 700 – 800 mm | ||

| Requirements for Product Can Diameter | ENKG-01: φ55 mm – φ120 mm | |

| ENKGD-01: φ55 mm – φ160 mm |

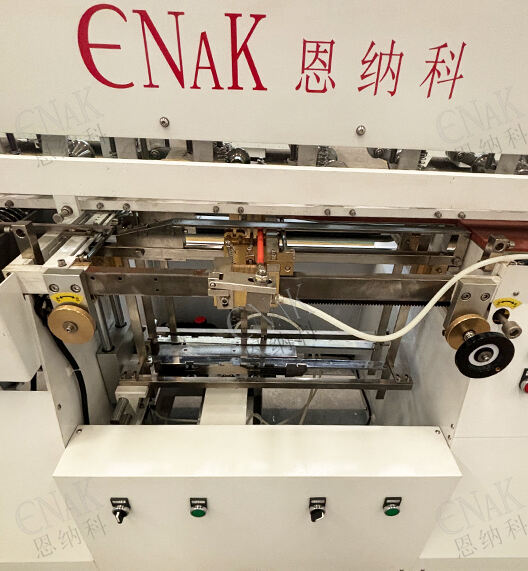

Main Structure and Functions

⑴ Labeling Machine Frame Section

The main side panels/frame is constructed by welding angle steel with a plate thickness of δ5.0mm. The base material is carbon steel sheets, which are finished with baking paint for anti-rust protection, and the entire frame is manufactured strictly according to actual dimensional requirements to ensure structural stability.

⑵ Conveying Carrier Section of the Labeling Machine

The main side panels of the modular mesh chain plate are made by bending and welding SUS304 stainless steel sheets with a plate thickness of δ2mm. SUS304 stainless steel is selected for its corrosion resistance and smooth surface, which is suitable for contact with cans and easy to clean.

The core component of this section is the modular mesh conveyor chain plate, which is responsible for stably conveying cans through the labeling station during the production process.

⑶ Carrier Conveyor Frame Section

The frame of this section is welded from 60×60×2.0mm square tubes, using SUS304 stainless steel as the base material to ensure durability and resistance to harsh workshop environments (such as humidity or minor chemical exposure).

Auxiliary components include pillow block bearings (for smooth rotation of conveying shafts) and various SUS304 screws (to ensure secure assembly and prevent rusting).

The power source is a **worm gear reduction motor** with a power rating of P=0.55/0.75KW, which provides stable, low-noise power for the conveyor system and adapts to different conveying speed requirements.

Material Specifications

Frame: Made of SS41 (also known as A3 steel), a general-purpose carbon structural steel with good load-bearing capacity. The surface is treated with spray painting to enhance anti-rust performance, making it suitable for non-contact, load-bearing frame parts.

Shaft: Uses S45C bearing steel, a high-quality carbon structural steel with excellent hardness and wear resistance. This material ensures the shaft maintains stable rotation performance during long-term operation and reduces mechanical wear.

Conveying Parts: All components involved in conveying (such as the modular mesh chain plate and conveyor rails) are made of 304 stainless steel, which meets hygiene standards and is easy to maintain.

Material-Contact Surface: Refers to the parts that directly come into contact with cans. It is composed of 304 stainless steel (for structural support and hygiene) and high-molecular wear-resistant strips (to reduce friction between cans and the conveyor surface, protecting both the cans and the equipment while extending service life).

Advantages

1. Label feeding is achieved via a hydraulic cylinder, and the machine is equipped with two sets of label-feeding mechanisms that can operate alternately. There is no need to stop the machine when reloading labels (this function is not supported for labels with a width of less than 35mm).

2. The glue supply for the label tail is controlled by a photoelectric sensor, which dispenses glue only when a can is detected and stops glue supply when there is no can.

3. Changing the can type is simple and requires minimal replacement of parts.

4. For the parts in contact with materials, the internal rails of the machine use high-molecular wear-resistant strips, which significantly reduce wear on the can bodies.

5. For two-piece cans, an additional glue spot is added to ensure the label adheres more firmly.

6. Glue is only applied to the two ends of the label, resulting in low glue consumption and reduced labeling costs.

7. 95% of the electrical components are from well-known brands, offering stable and efficient performance while greatly saving labor.

8. The machine produces low noise, with a noise level of less than 75 dB, complying with international standards.