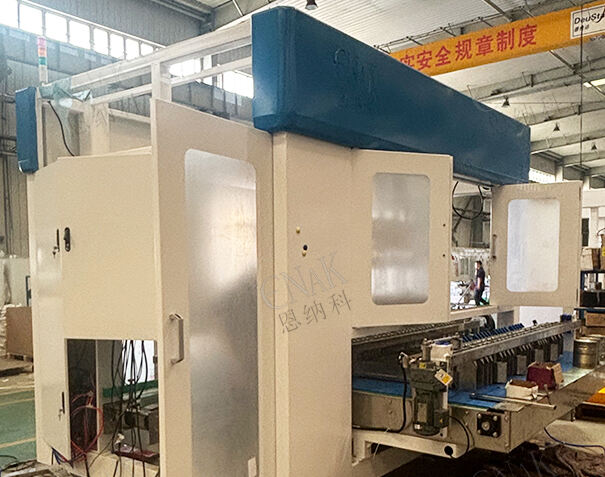

Description

Core Control & Automation Level:

The Production Line Full Automatic Case Packer adopts servo + PLC control technology for its main transmission, paired with a German SIEMENS programmable controller. It features fast communication and strong diagnostic capabilities, with a system reliability of 99.5%. Combined with a human-machine interface, it realizes stepless speed regulation, offering easy operation, a compact structure, and high automation, which significantly reduces manual intervention.

Working Performance & Stability:

Special pneumatic components are used to grasp and place products. Through mechanical operation combined with pneumatic, electrical, and optical control, the machine realizes automatic operations of product lifting, translation, and lowering. The movements are coordinated, stable, and accurate. The carton conveying channel adopts a pressure-free control design, and the bottle conveying system is equipped with imported high-quality integral mesh chains and transition plates to ensure smooth connection with the customer's conveyor belt. The entire system automatically adjusts the case packing speed according to the product feeding speed on the conveyor belt.

Hygiene & Operation Advantages:

Oil-free lubrication pneumatic components are adopted, and most moving parts feature a user-friendly design that requires no oil injection lubrication for life. This reduces significant usage costs for users, simplifies daily maintenance, and ensures low noise and no oil pollution, meeting food hygiene requirements. Multiple carton feeding methods are available: manual, automatic, and continuous fast feeding. The gripper supports manual and automatic operations, with small on-site footprint and large operation space. Multiple protection functions are set to stop the machine in time when faults occur, such as automatic shutdown when there are not enough cartons on the carton feeding belt, not enough bottles on the bottle conveying table, or misalignment between the gripper and the carton.

Product Advantages

Four-Level Pressure Reduction Design, Eliminating Bottle Tipping Risks:

The Production Line Full Automatic Case Packer innovatively adopts a four-level pressure reduction solution to ensure stable product conveying from the source. The first-level pressure reduction is achieved through the speed difference between the bottle feeding conveyor and the front conveyor to avoid product stacking and collision. The pneumatic bottle stop device provides the second-level pressure reduction to reduce the conveying impact. The cylinder at the end of the conveyor implements two levels of pressure reduction to further buffer the speed. With full pressure reduction, the alignment error between the gripper and the product is ≤ 0.3mm. After entering the case packing process, the product is in a pressure-free and stable state, and the bottle tipping rate is controlled below 0.1%. It is especially suitable for easily tip-over glass bottles and soft packaging products, reducing losses.

German IGUS Linear Positioning System, Stable and Durable:

Equipped with the German IGUS linear positioning system, the Production Line Full Automatic Case Packer has a positioning accuracy of ±0.1mm and precise movement, which effectively reduces the impact and vibration during equipment operation. This improves the operation stability and reliability of the equipment by 40%, avoiding component wear or product displacement caused by vibration. The system adopts a lubrication-free and maintenance-free design, eliminating the need for regular oil addition. It not only reduces maintenance workload but also avoids oil pollution, meeting the hygiene requirements of the food and pharmaceutical industries. Its service life is 3 times longer than that of traditional positioning systems, reducing equipment replacement costs.

High-Quality Materials & Safety Protection, Compliant and Reliable:

The main body of the Production Line Full Automatic Case Packer is made of stainless steel (parts in contact with products), aluminum alloy (transmission structure), engineering plastics (protective shell), and carbon steel with spray plating (frame). Stainless steel is corrosion-resistant and easy to clean, meeting food industry hygiene standards; aluminum alloy is lightweight yet strong, reducing equipment weight; carbon steel spray plating enhances rust resistance and extends the overall service life of the equipment. Meanwhile, the equipment is equipped with fully enclosed safety guards and photoelectric sensors, fully complying with the national standard GB 12265.1-2007 "Mechanical Safety - Safety Distances to Prevent Upper Limbs from Reaching Hazardous Areas" and eliminating operational safety accidents.

Application Scenarios

Food and Beverage Industry Production Lines:

The Production Line Full Automatic Case Packer is suitable for case packing of bottled water, fruit juice, canned foods, dairy products, etc. For example, it can neatly pack 550ml bottled water in 24 bottles per carton or layer 330ml canned foods for packing. The oil-free lubrication design avoids food pollution, and the four-level pressure reduction ensures stable conveying of glass bottles and tin cans, adapting to the large-scale and high hygiene standard production needs of the food industry. It can be seamlessly connected with filling and labeling production lines.

Daily Chemical Care Production Lines:

It can be used for case packing of daily chemical products such as shampoo, body wash, and laundry detergent. For instance, it can pack 750ml shampoo PE bottles in 12 bottles per carton in multiple rows. With a small footprint, it is suitable for the compact workshop layout of daily chemical enterprises. The German IGUS positioning system ensures accurate grasping of special-shaped bottles (such as flat bottles and curved bottles), avoiding label wear and improving the packaging appearance of products.

Pharmaceutical and Health Product Production Lines:

Meeting the hygiene and safety requirements of the pharmaceutical industry, the Production Line Full Automatic Case Packer can be used for case packing of pharmaceutical glass bottles (such as oral liquid bottles) and health product PE bottles. The lubrication-free design reduces cleaning dead corners, and multiple fault protection functions avoid product pollution. The automatic speed adjustment function of the bottle conveying system can adapt to the small-batch and multi-specification production rhythm of pharmaceutical products, ensuring a sterile and accurate case packing process.

Frequently Asked Questions

Q1: Can the Production Line Full Automatic Case Packer adapt to different sizes of product packaging?

A1: Yes. The parameters of the gripper and conveyor can be flexibly adjusted through the human-machine interface. It supports products with a diameter of 50-150mm and a height of 80-300mm, no need to replace core components. The adaptation process takes only 10 minutes, meeting the needs of multi-specification product co-line production.

Q2: What daily maintenance work is required for the equipment?

A2: Daily maintenance only involves cleaning and inspection - wipe the equipment surface and mesh chain conveyor with a dust-free cloth every day; check whether the safety protection devices are intact every week; check whether the air pressure of pneumatic components is normal every month. No complex lubrication maintenance is needed, and the maintenance cost is low.

Q3: How to quickly resume production if the Production Line Full Automatic Case Packer breaks down?

A3: The equipment is equipped with a fault self-diagnosis function. When a fault occurs, the human-machine interface will display the fault cause (such as "lack of bottles" "alignment deviation") and solutions, and the operator can handle it according to the prompts. If technical support is needed, the after-sales team will respond within 2 hours and provide on-site service in provincial capital cities within 24 hours.

If you have questions about the quotation, customization needs (such as adaptation to special products), or on-site test run arrangement of the Production Line Full Automatic Case Packer, please leave your company name, contact information, and product specifications. Our professional sales team will contact you within 24 hours and provide a customized automatic case packing solution to help improve the efficiency of your production line!