Project Requirements

When managing large-scale production lines in the food and beverage sector, ensuring both speed and hygiene is an ongoing challenge. Bottles must be thoroughly cleaned before filling to eliminate contaminants, residues, or microorganisms that could compromise product safety and quality. As a project manager overseeing production optimization, I quickly realized that conventional cleaning systems were no longer sufficient to meet our operational needs.

The demand was clear: we needed an industrial bottle washing machine capable of delivering reliable cleaning performance at high throughput levels. The system had to support continuous operation, reduce downtime, and ensure compliance with international hygiene regulations. According to industry research, approximately 70% of quality-related production issues stem from insufficient container preparation. This highlighted the urgency to integrate a solution that could deliver both capacity and precision.

Key requirements from our production team included:

A machine that could handle large volumes of bottles simultaneously, maintaining consistent output during peak periods.

Automated entry and exit of bottles to reduce reliance on manual labor and prevent bottlenecks.

High-pressure cleaning technology to achieve complete residue removal, especially for sticky liquids such as dairy or juice products.

After evaluating various technologies, the decision was made to implement an industrial bottle washing machine designed specifically for large-scale applications. Its combination of multi-station cycle rinsing, automated bottle handling, and a robust high-pressure spraying system promised to align perfectly with the project’s objectives: higher efficiency, superior cleanliness, and seamless integration into the existing production line.

Core Technical Features

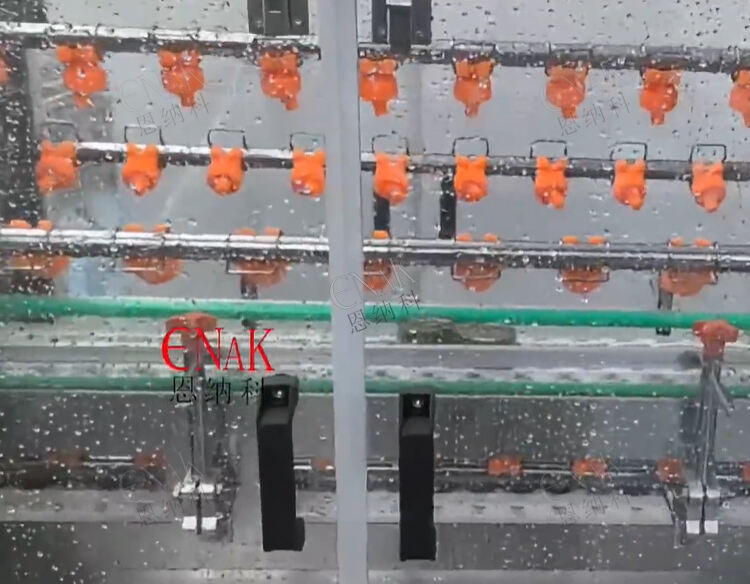

The success of the industrial bottle washing machine lies in its three defining technical features: multi-station cycle rinsing, automatic infeed and outfeed, and high-pressure spraying.

1. Multi-station cycle rinsing

Unlike single-stage washers, this machine incorporates multiple stations that operate in a continuous cycle. Bottles pass through sequential rinsing and spraying zones, each designed to tackle specific residues. For instance, an initial rinse removes larger debris, while subsequent stages apply pressurized water jets or cleaning solutions. This multi-station approach not only enhances cleaning consistency but also ensures scalability for high-capacity production. The design allows for hundreds of bottles to be processed simultaneously, making it indispensable for large factories.

2. Automatic infeed and outfeed

Efficiency in modern production relies heavily on automation. The industrial bottle washing machine integrates automatic bottle loading and unloading systems, eliminating manual intervention in these stages. Bottles are smoothly guided into the washing chamber via synchronized conveyors, while clean bottles exit directly to the filling line. This automation reduces labor requirements, minimizes the risk of human error, and ensures a steady production rhythm. For project managers, this translates into predictable cycle times and improved coordination between upstream and downstream operations.

3. High-pressure spraying system

The third critical feature is the machine’s high-pressure spraying technology. Bottles are exposed to targeted jets that reach every internal and external surface, effectively removing residues that standard rinsing cannot. This is particularly valuable when handling bottles used for viscous liquids such as sauces or dairy beverages. The high-pressure system not only ensures thorough cleaning but also reduces water consumption by recycling spray streams where possible.

Collectively, these three features create a robust cleaning solution tailored for industrial environments. From a technical management perspective, the machine demonstrates durability, energy efficiency, and compliance with stringent safety standards, making it a future-ready investment for any production line.

Product Application Process

When implementing the industrial bottle washing machine, our project team followed a structured deployment process to ensure smooth integration with existing production lines.

Step 1: Assessment and line preparation

We began by analyzing bottle flow, line capacity, and space constraints. The modular design of the industrial bottle washing machine allowed us to configure the system for both current capacity and future expansion. By conducting simulations, we verified that the machine could align with filling and packaging equipment without disrupting cycle times.

Step 2: Installation and automation integration

The installation process was streamlined by the machine’s modular architecture. Automatic infeed conveyors were connected to upstream depalletizers, while the outfeed section was synchronized with filling stations. Control systems were integrated into the plant’s central PLC, allowing operators to monitor machine status, cycle times, and cleaning performance in real time. This step was crucial for ensuring seamless coordination across the production floor.

Step 3: Operational trials and fine-tuning

During trial runs, the multi-station rinsing function demonstrated its effectiveness. Bottles previously cleaned using manual methods showed visible improvements when processed through the industrial bottle washing machine. High-pressure spray jets reached deep recesses of bottles, ensuring no residue remained. Adjustments to infeed and outfeed speeds were made to optimize synchronization with the rest of the line. The adjustable speed capability of the conveyors proved essential in balancing high throughput with cleaning precision.

Step 4: Full-scale operation

Once trials were completed, the machine was incorporated into daily production. The automatic bottle entry and exit reduced manpower requirements by approximately 40%, freeing staff to focus on higher-value tasks. Through data monitoring, we observed a 25% increase in throughput and a significant drop in bottle rejection rates. The high-pressure spray system also reduced water usage compared to our previous system, supporting sustainability goals.

Step 5: Ongoing maintenance and monitoring

To maintain peak efficiency, the project team implemented a preventive maintenance program. Operators were trained to perform quick inspections of spray nozzles, conveyors, and filters. The modularity of the system ensured that if one section required servicing, it could be isolated without shutting down the entire machine.

The results spoke for themselves. By adopting the industrial bottle washing machine, the production line achieved greater consistency, higher efficiency, and better compliance with hygiene standards. From a project management perspective, the investment delivered measurable returns within the first year, both in cost savings and in customer satisfaction.

Conclusion

From the viewpoint of a project manager, the implementation of the industrial bottle washing machine has been a critical milestone in optimizing production efficiency. The system’s multi-station cycle rinsing ensures that cleanliness standards are consistently achieved, even under the pressure of high-volume operations. The automated infeed and outfeed mechanisms significantly reduce labor dependency, eliminating manual bottlenecks and ensuring steady production flow. Meanwhile, the high-pressure spraying system guarantees a thorough clean, enhancing product safety and compliance with industry regulations.

Beyond these technical advantages, the industrial bottle washing machine has also strengthened operational resilience. Its modular structure allows for flexibility in scaling, while automation ensures predictability in cycle times and output. For large-scale production environments where downtime directly translates into lost revenue, these features provide tangible competitive advantages.

Industry data indicates that demand for advanced cleaning equipment is expected to grow in tandem with global beverage and food consumption. By adopting this solution, our production facility not only resolved immediate challenges but also positioned itself for long-term success. The machine has improved throughput, reduced rejection rates, and enhanced sustainability by optimizing water usage.

In conclusion, the industrial bottle washing machine is more than just equipment—it is an enabler of efficiency, compliance, and growth. For project managers tasked with balancing cost, quality, and capacity, this technology offers a comprehensive solution. It demonstrates how advanced engineering and thoughtful integration can transform bottle cleaning from a potential bottleneck into a high-performance asset within the production line.