Technical Background

The food and beverage industry is under constant pressure to meet high hygiene standards, achieve faster turnaround times, and optimize efficiency in every stage of production. Among all these processes, bottle washing remains a crucial step to guarantee product quality and regulatory compliance. Contaminants or residues inside bottles can directly impact consumer safety, brand reputation, and operational costs. According to recent industry data, inefficient washing systems contribute to as much as 15% of rejected packaging batches in bottling plants. Therefore, selecting a reliable bottle washer is not simply an equipment decision—it is a strategic investment in food safety and production sustainability.

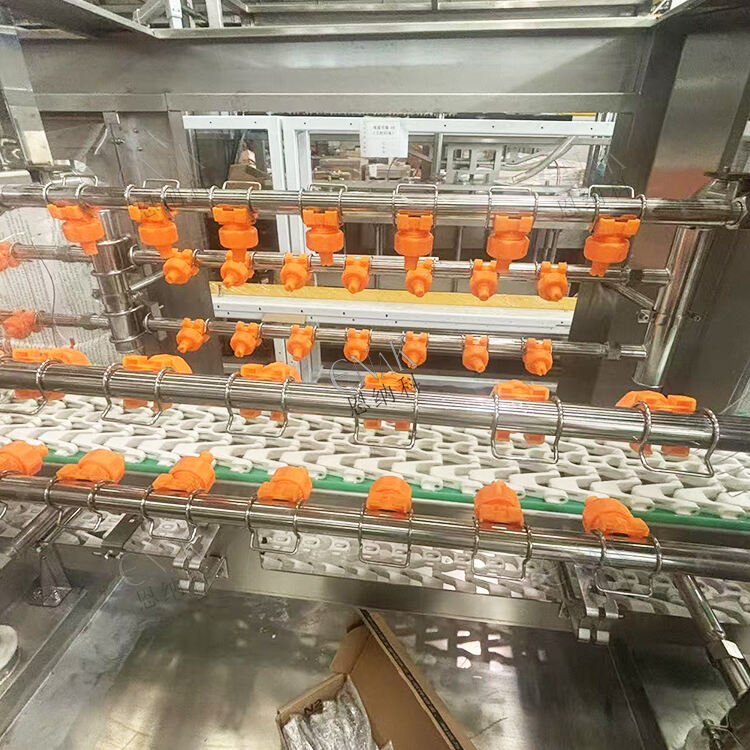

Tianjin ENAK has developed bottle washer equipment that integrates state-of-the-art mechanical engineering with streamlined production line compatibility. A distinctive advantage is the integration of a belt conveyor system that manages bottle transportation throughout the washing cycle. The belt conveyor ensures stable and synchronized bottle handling, minimizing jamming or tipping that could otherwise slow production. In contrast to older systems, this modern solution uses adjustable conveying speeds to align with varying production rhythms, making it suitable for small-scale batch runs as well as large-scale industrial operations.

From a market perspective, the bottle washer not only addresses operational efficiency but also reduces labor dependency and ensures compliance with food safety regulations. Its modular design ensures scalability, while the built-in safety features such as anti-slip belt conveyor design enhance reliability. For food producers aiming to expand capacity or diversify product lines, this equipment represents a balance between technical robustness and market adaptability.

Core Technical Features

The competitive advantages of Tianjin ENAK’s bottle washer equipment can be broken down into three technical pillars: adjustable conveying speed, modular structure, and safety through anti-slip design.

1. Adjustable conveying speed

One of the most critical innovations is the ability of the belt conveyor to operate at variable speeds. In practical terms, this means that production managers can align bottle washing cycles with upstream filling and downstream packaging processes. For example, when working with high-volume soda bottling, the belt conveyor can run at maximum speed to match rapid filling lines. Conversely, in premium beverage production where washing must be more thorough, the conveyor speed can be reduced without compromising line balance. This flexibility is essential for plants handling multiple product categories or seasonal fluctuations in demand.

2. Modular structure for installation and maintenance

The second advantage lies in the modular engineering of the belt conveyor and washing units. Traditional systems often require extensive downtime for installation or servicing, but ENAK’s design allows plant engineers to disassemble, clean, or upgrade specific sections without halting the entire line. Each conveyor segment can be replaced independently, reducing mean time to repair (MTTR) and keeping total cost of ownership under control. Moreover, modularity ensures scalability: a factory can start with a basic washing setup and expand by adding new conveyor sections as production grows.

3. Anti-slip design for safe material handling

Safety in bottle handling is paramount, especially in high-speed environments where slippage or bottle tipping can cause product loss and machine damage. The ENAK belt conveyor incorporates anti-slip materials and precise alignment guides, ensuring that bottles remain stable even during acceleration or deceleration phases. This reduces breakage, minimizes contamination risks, and enhances operator confidence in line performance.

Additional features include stainless steel construction for durability, energy-efficient motors that reduce operational costs, and easy integration with existing automation frameworks. When combined, these features demonstrate that the belt conveyor is not just a component but a key enabler of operational reliability, hygiene, and scalability in food processing plants.

Product Application Solutions

The application of Tianjin ENAK’s bottle washer equipment spans a wide range of use cases in the food and beverage industry. Here we illustrate how the belt conveyor system and core design features translate into real-world operational benefits.

Application in high-speed beverage bottling

In carbonated drink production, efficiency is everything. Bottles must be washed, dried, filled, capped, and packaged within seconds. ENAK’s bottle washer uses a synchronized belt conveyor that ensures bottles are consistently aligned for nozzle insertion and cleaning. The adjustable speed function allows the equipment to ramp up throughput during peak demand while slowing down for quality-sensitive batches. As a result, plants can maintain both flexibility and efficiency without investing in multiple washing systems.

Application in dairy and health drinks

Products such as yogurt drinks or probiotic beverages require exceptionally clean containers. Here, the belt conveyor’s steady motion minimizes turbulence and prevents cross-contamination. The anti-slip design ensures glass or lightweight PET bottles remain securely positioned, even under wet conditions. Industry reports suggest that introducing modular belt conveyor systems in dairy production reduces bottle damage rates by nearly 25%, saving both material and reprocessing costs.

Application in breweries and specialty beverages

Breweries often work with diverse bottle shapes and sizes, which can create challenges in washing equipment. ENAK’s modular belt conveyor design enables quick adjustments to accommodate different bottle geometries. Operators can add or remove conveyor sections to adapt the system for short runs of specialty brews without interrupting standard production. The anti-slip surface prevents bottle clinking or collisions, preserving product quality and reducing waste.

Application in multi-line factories

Large-scale food manufacturers frequently operate multiple lines producing various beverages. ENAK’s bottle washer provides a standardized belt conveyor platform across all lines, simplifying training and reducing spare parts inventory. With modular upgrades, factories can harmonize maintenance schedules and reduce downtime across departments. The ability to synchronize conveyor speeds with filling machines and packaging lines ensures consistent overall equipment effectiveness (OEE).

Market-level perspective

From a marketing standpoint, these application scenarios highlight the competitive advantages companies gain by adopting ENAK’s solution. Reduced downtime, lower product loss, and adaptable throughput translate into tangible cost savings. More importantly, the hygienic design and reliability of the belt conveyor enhance compliance with international food safety standards, giving manufacturers a strong message to communicate to consumers and business partners. The result is not just a technical upgrade, but a strategic differentiation in an increasingly competitive food industry.

After-Sales Assurance

Beyond technology and applications, after-sales support defines the long-term value of equipment. Tianjin ENAK positions its bottle washer equipment as a strategic investment backed by comprehensive service guarantees.

First, modular belt conveyor sections are designed for quick replacement, and spare parts are standardized, ensuring short lead times. This reduces the risk of extended downtime due to supply chain delays. Secondly, technical support teams provide on-site commissioning and operator training, ensuring that plant personnel fully understand how to adjust belt conveyor speeds, replace components, and maintain the anti-slip system.

Additionally, ENAK emphasizes preventive maintenance programs. By providing monitoring guidelines—such as vibration checks, belt conveyor tracking alignment, and wear detection—customers can shift from reactive repairs to predictive maintenance. This proactive model not only extends equipment life but also stabilizes production schedules.

From a warranty standpoint, coverage includes both the belt conveyor modules and washing components, with transparent policies that minimize uncertainty for procurement managers. Many customers report that after-sales responsiveness is just as valuable as technical features, and ENAK leverages this strength to build long-term partnerships.

In summary, the after-sales package reinforces the technical advantages of the bottle washer. It ensures that the adjustable speed conveyor remains properly calibrated, that modularity continues to provide flexibility, and that the anti-slip design maintains its safety performance throughout the equipment lifecycle. For decision-makers in the food industry, this combination of advanced engineering and dependable service translates into confidence—not only in day-to-day operations but also in long-term strategic planning.