Comprehensive Applications and Company Strengths As a leading high-tech enterprise specializing in end-to-end packaging solutions, our company provides innovative turnkey projects for fish canning production and downstream packaging lines. We integra...

As a leading high-tech enterprise specializing in end-to-end packaging solutions, our company provides innovative turnkey projects for fish canning production and downstream packaging lines. We integrate cutting-edge R&D, precision engineering, advanced manufacturing, and comprehensive after-sales support to deliver complete solutions for various fish processing applications including sardines, yellow croaker, tuna, ribbon fish, and dace. Our expertise spans pre-made food, canning production, and packaging automation, making us the preferred partner for manufacturers seeking reliable and efficient processing solutions.

What distinguishes us is our deep understanding of the unique challenges in fish processing. We recognize that different fish species require specialized handling - from delicate tuna requiring gentle processing to robust sardines needing precise portion control. Our equipment is engineered to handle these variations while maintaining the highest standards of food safety and quality compliance with international regulations including FDA, EU, and BRC standards.

Our integrated approach combines Industry 4.0 technologies with practical manufacturing expertise. We incorporate IoT connectivity, real-time monitoring systems, and predictive maintenance capabilities to ensure our clients achieve optimal operational efficiency. This technological edge, combined with our commitment to customer success, provides clients with the assurance that our solutions are not just applicable but optimized for their specific production requirements.

|

|

|

|

Our comprehensive cleaning system handles the initial processing stages with exceptional efficiency. The system features multi-stage washing chambers with adjustable water pressure systems, mechanical brushing units, and optical sorting technology. The automated descaling and gutting modules can process up to 5 tons of fish per hour while maintaining product integrity. The water recycling system reduces consumption by up to 70% compared to conventional systems.

Ensures consistent raw material quality while reducing labor costs by up to 80%. The automated processing minimizes product damage and improves yield by approximately 15%. The system's compliance with food safety standards significantly reduces audit risks and ensures market access.

Our advanced filling systems employ weight-based portion control with accuracy within ±1 gram. The servo-driven mechanisms handle various fish sizes and types, from whole sardines to chunked tuna. The system features quick-change tooling that allows for format changes in under 10 minutes. Special anti-jamming technology ensures smooth operation even with challenging product types.

Reduces product giveaway by 3-5% through precise portion control. Increases production flexibility enabling manufacturers to run multiple products on the same line. The gentle handling maintains product appearance and quality, enhancing brand value.

Our steam cooking systems provide precise temperature control (±1°C) and uniform heat distribution throughout the retort chambers. The automated loading and unloading systems handle baskets up to 1000kg capacity. The integrated recipe management system stores multiple cooking profiles for different products.

Ensures consistent product quality and food safety with 99.9% sterilization efficiency. Reduces energy consumption by 30% through optimized thermal recovery systems. The automated handling minimizes physical labor and improves working conditions.

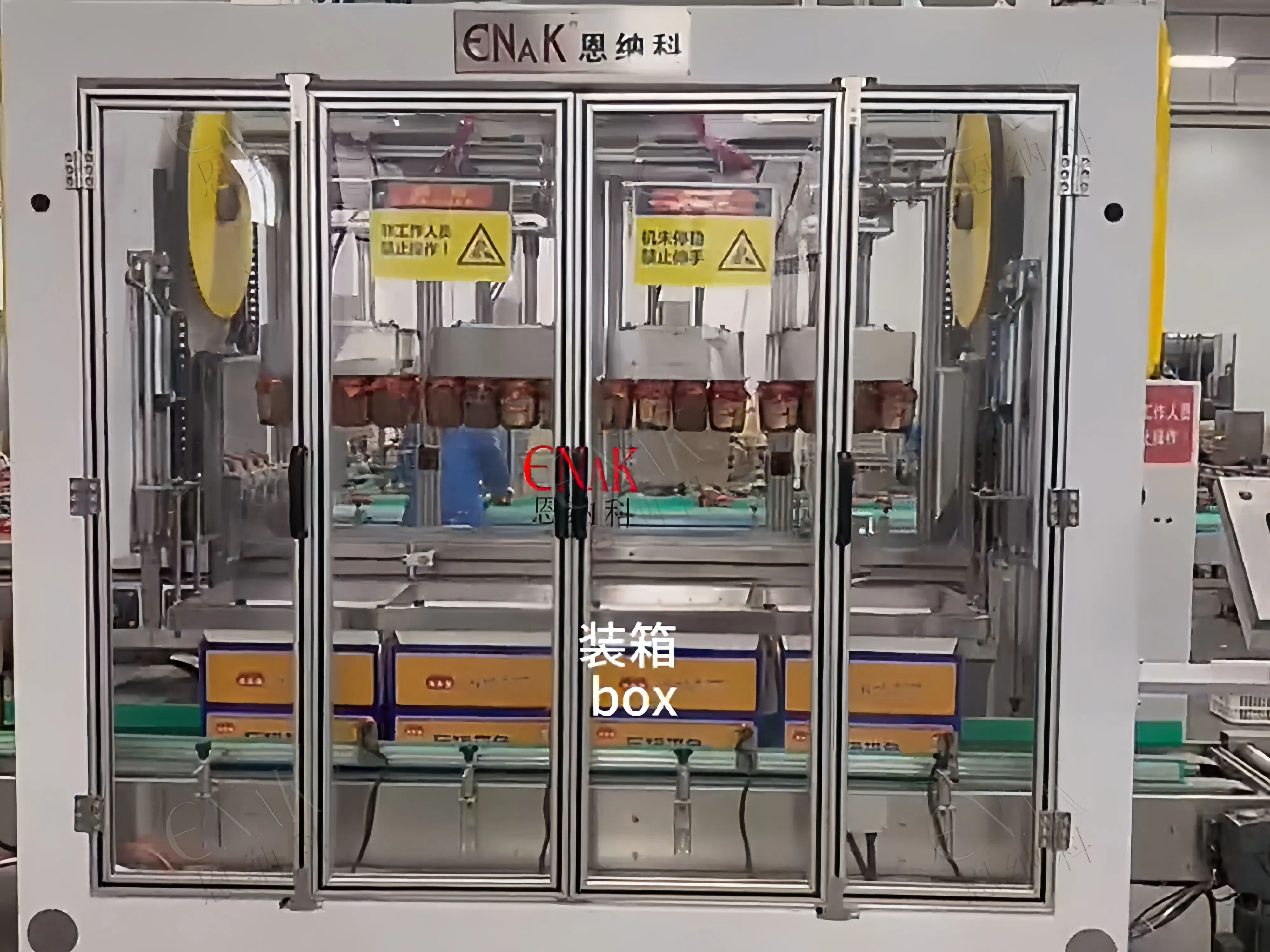

Our end-of-line packaging solutions include robotic case packing, automatic lid placement, and palletizing systems. The integrated vision guidance ensures accurate package placement, while the flexible handling system accommodates various case sizes and patterns.

Reduces manual labor by 85% in the packaging area. Increases output consistency and reduces product damage during handling. The system's flexibility supports multiple SKUs and seasonal product variations.

Our technological excellence is demonstrated through numerous successful implementations worldwide. A major tuna processor in Thailand implemented our complete processing line and achieved a 40% increase in production capacity while reducing operating costs by 25%. The automated cleaning system improved yield by 18%, and the precision filling system reduced product giveaway by 4%, resulting in annual savings exceeding $500,000.

In Portugal, a sardine canning company integrated our cooking and sealing systems, achieving 99.8% quality approval rate during regulatory audits. The project resulted in 35% reduction in energy consumption and 50% decrease in production waste. The client reported complete elimination of customer complaints related to can integrity within the first quarter of operation.

In the competitive fish processing industry, our canning and packaging solutions provide the technological advantage manufacturers need to excel. Whether you're modernizing existing operations or establishing new production facilities, our expertise and innovative technology can help you achieve superior operational efficiency, exceptional product quality, and sustainable competitive advantage.

We invite you to experience our commitment to excellence firsthand. Contact our solutions team today to schedule a comprehensive virtual demonstration tailored to your specific products and production requirements. For existing operations, inquire about our complimentary production line assessment that identifies improvement opportunities with detailed ROI calculations.

Join industry leaders who have transformed their operations with our technology. Let's build the future of fish processing together – contact us today to start your journey toward manufacturing excellence.

Copyright © ENAK(Tianjin) Automation Equipment Co.,Ltd. | Privacy policy