Company Overview and Core Competencies As a leading high-tech enterprise specializing in complete packaging solutions, our company delivers innovative turnkey projects for golden bowl canning production and downstream packaging operations. We integra...

As a leading high-tech enterprise specializing in complete packaging solutions, our company delivers innovative turnkey projects for golden bowl canning production and downstream packaging operations. We integrate cutting-edge R&D, precision engineering, advanced manufacturing, and comprehensive technical support to provide complete solutions for various premium food products including specialty foods, ready-to-eat meals, and gourmet ingredients. Our expertise spans pre-made food, canning production, and automated packaging systems, establishing us as the preferred partner for manufacturers seeking reliable and efficient processing solutions worldwide.

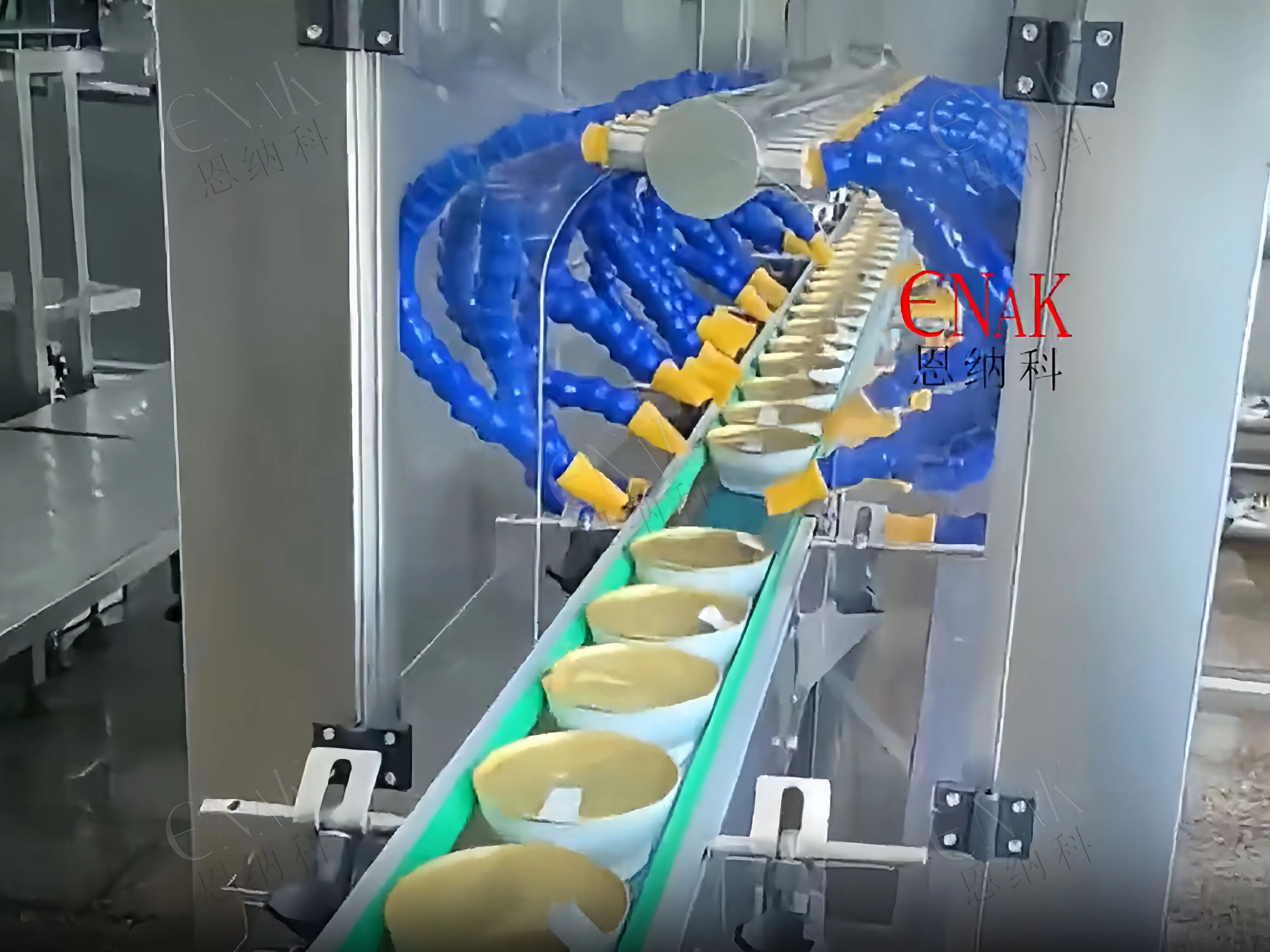

What distinguishes us is our deep understanding of the unique requirements in golden bowl packaging. We recognize that the distinctive bowl shape requires specialized handling systems and customized solutions. Our equipment is specifically engineered to handle this unique container format while maintaining the highest standards of food safety and quality compliance with international regulations including FDA, EU, and BRC standards.

Our integrated approach combines Industry 4.0 technologies with practical manufacturing expertise. We incorporate IoT connectivity, real-time monitoring systems, and predictive maintenance capabilities to ensure our clients achieve optimal operational efficiency. This technological advantage, combined with our commitment to customer success, provides clients with the confidence that our solutions are specifically optimized for golden bowl packaging requirements.

Our custom-designed cleaning system features gentle yet effective cleaning technology specifically engineered for golden bowl containers. The system utilizes food-grade sanitizing solutions and high-purity water rinsing with precise temperature control. The unique bowl-handling mechanism ensures thorough cleaning without damaging the container's special coating or decorative elements.

Ensures 100% cleaning effectiveness while maintaining bowl integrity. Reduces water consumption by 40% through advanced recycling systems. Eliminates manual handling, reducing labor costs by 70%.

Our specialized filling systems are designed to handle the unique geometry of bowl containers. The multi-stage filling technology ensures precise portion control for both solid and liquid components. The system features vision-guided positioning and anti-drip nozzles that prevent product contamination on sealing surfaces.

Achieves filling accuracy within ±0.5% for consistent product quality. Reduces product waste by 4-6% through precise portion control. Enables quick changeovers between different products in under 10 minutes.

Our custom sealing technology ensures perfect closure for golden bowl containers. The system features adaptive sealing heads that accommodate the unique rim design and maintain consistent pressure distribution. Integrated quality control systems perform 100% seal integrity checks using advanced sensor technology.

Reduces leakers to less than 0.05%, virtually eliminating product returns. Preserves product freshness and extends shelf life. Minimizes maintenance requirements through self-adjusting mechanisms.

Our specialized labeling systems are engineered for perfect application on curved bowl surfaces. The precision applicators ensure bubble-free placement with accuracy within ±0.3mm. The system handles various label materials including metallic finishes and special coatings that complement the golden bowl appearance.

Enhances brand presentation with flawless label application. Reduces label waste by 30% through precision application technology. Supports multiple label designs and sizes without mechanical adjustments.

Our integrated packaging line includes automatic case sealing, coding, and palletizing systems. The robotic palletizers handle finished cases with precision stacking patterns. The system features real-time monitoring of packaging quality and production output.

Increases packaging speed by 45% compared to manual operations. Reduces product damage during handling to less than 0.2%. Provides complete traceability from individual bowls to palletized shipments.

In Germany, a specialty food company integrated our sealing and labeling systems, achieving 99.95% quality approval rate during regulatory audits. The project resulted in 38% reduction in material waste and 42% decrease in energy consumption. The client reported complete elimination of customer complaints related to packaging defects within the first quarter of operation.

A US-based gourmet food producer implemented our IoT-enabled processing line and achieved unprecedented operational visibility. The real-time monitoring system reduced unplanned downtime by 48% through predictive maintenance alerts, while the automated material handling system reduced labor requirements by 30 positions. The comprehensive data analytics enabled an additional 25% productivity improvement through optimized production scheduling.

In the competitive premium packaging industry, our golden bowl canning and packaging solutions provide the technological advantage manufacturers need to excel. Whether you're launching a new product line or modernizing existing operations, our expertise and innovative technology can help you achieve superior operational efficiency, exceptional product quality, and sustainable competitive advantage.

We invite you to experience our commitment to excellence firsthand. Contact our engineering team today to schedule a comprehensive virtual demonstration tailored to your specific golden bowl products and production requirements. For existing operations, inquire about our complimentary production line assessment that identifies improvement opportunities with detailed ROI calculations.

Join the industry leaders who have transformed their operations with our technology. Let's build the future of premium packaging together – contact us today to start your journey toward manufacturing excellence.

Copyright © ENAK(Tianjin) Automation Equipment Co.,Ltd. | Privacy policy