Description

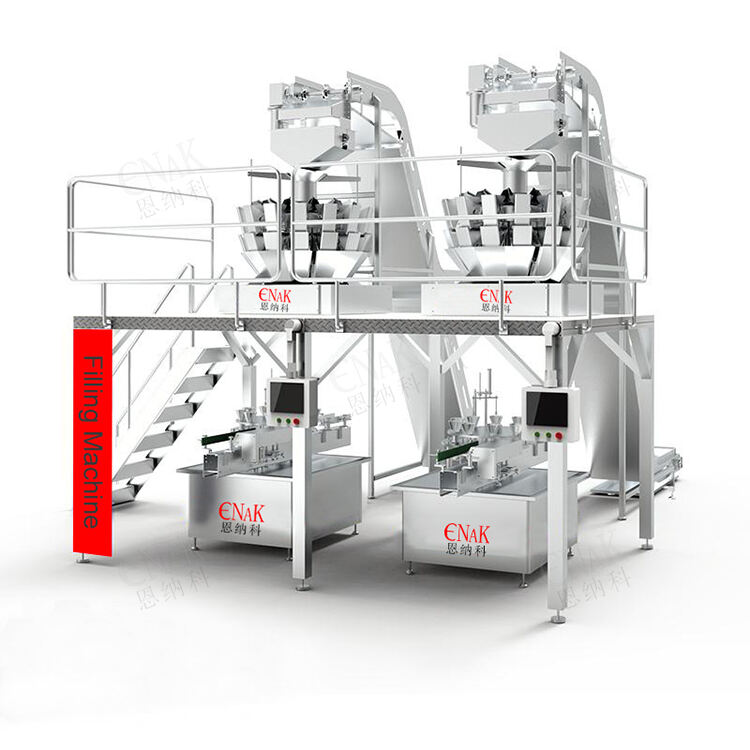

The Automatic Solids Multi-Head Scale Filling Machine, developed by Tianjin ENAK Machinery Co., Ltd, is a high-end automated filling solution specifically designed for powders, granules, grains, seasonings, and small solid materials. Its core system combines multi-head weighing with intelligent control technology, enabling high-precision, multi-specification, and multi-mode solid filling. This machine meets modern production lines’ requirements for efficiency, flexibility, and safety.

| key machines | Pasteurizer, Fryer, Mixer, Heat Exchanger, Conveyor, Carton… | voltage | 380V |

| automatic grade | Automatic | product type | Ice cream, SEAFOOD, CANDY, Vegetables, Chocolate, Fruit… |

| Capacity | OEM | brand name | LWT |

| dimension(l*w*h) | OEM | place of origin | Shanghai, China |

| power | 2.5KW | Product name | Canned Mushroom Production Line |

| Type | Fully Automatic | Name | Mushroom Processing Machine |

| Function | Multifunctional | Usage | Food Industry Equipment |

| Capacity | 1~60 Tons | Feature | High Efficiency Easy Operate |

| Keywords | Mushroom Cleaning Washing Line | Processing Types | Mushroom Process Equipment |

| Application | Food Processing Machine |

Product Performance

Multi-Head Weighing System: Supports simultaneous multi-head weighing for precise control of each package’s weight, significantly improving production efficiency and filling accuracy.

High-Speed Filling Capability: Capable of filling thousands of packages per hour, suitable for large-scale production.

Intelligent Control: Equipped with PLC programmable logic controllers (PLC) and human-machine interface (HMI), offering intuitive operation and adjustable parameters for quick product changeovers

Modular Design: Compact and space-saving, easy to clean and maintain, ensuring long-term stable operation

Wide Application Range: Ideal for food, beverage, dairy products, edible oils, cosmetics, daily chemicals, and pharmaceutical industries, meeting diverse solid filling needs.

Product Advantages

1.Intelligent Control

PLC Programmable Control System: High-performance controller monitors the entire filling process in real time, ensuring stable and accurate weight per package.

Human-Machine Interface (HMI): Intuitive interface allows quick setting of weight, speed, and production parameters, while displaying real-time operational status.

Data Recording and Traceability: Automatically records production data for quality tracking, production analysis, and reporting, facilitating efficient management.

Rapid Changeover Capability: Enables fast adjustment for different materials and package sizes, minimizing downtime and increasing production flexibility.

Remote Monitoring and Diagnostics: Certain models support networked operation, allowing remote monitoring and fault diagnostics to enhance maintenance efficiency.

2.Multiple Filling Modes

Gravity/Normal Pressure Filling: Suitable for most powders and granules, especially dry, free-flowing materials, offering reliable and simple operation.

Vacuum Filling: Reduces dust generation and maintains material cleanliness, ideal for lightweight, easily airborne, or moisture-sensitive powders.

Piston Filling: Controls the filling volume precisely for high-viscosity or mixed granular materials, ensuring uniform weight and accuracy.

Flow Meter Filling: Delivers stable measurement for special flowable materials, improving filling consistency and accuracy.

Flexible Mode Switching: Users can switch between different filling modes according to material characteristics, ensuring high efficiency and precision across multi-product production lines.

3. Safety Protection Design

Emergency Stop Button: Key positions feature emergency stops for immediate shutdown to protect operators and equipment.

Protective Doors: Prevent operators from accessing moving parts during operation, reducing accident risk.

Multiple Sensor Monitoring: Includes hopper sensors, conveyor sensors, and filling status monitoring, with automatic alerts and shutdown in case of abnormalities.

Stable and Reliable: Comprehensive safety features ensure reliable operation even at high-speed production.

Operator Training and Safety Prompts: Built-in safety instructions and operational guidance enhance operator awareness and adherence to safety protocols.

4. Wide Application Range

Food & Beverage Industry: Efficiently fills rice, beans, grains, sugar powder, coffee powder, seasonings, and other powder or granular materials.

Dairy & Edible Oil Industry: Suitable for milk powder, powdered dairy products, oil granules, and blended granular materials.

Cosmetics & Daily Chemicals: Handles loose powders, granular cosmetics, and raw materials for personal care products.

Pharmaceutical Industry: Accurately fills powdered or granular drugs in compliance with GMP and pharmaceutical safety standards.

Versatility Across Industries: One machine can meet multiple industry production needs, improving ROI and supporting multi-product lines.

Production Process & Application

1. Material Feeding & Conveying

Uses vibratory hoppers, screw conveyors, or vacuum feeding systems to transport powders or granules evenly to the multi-head weighing system, ensuring stable and precise filling.

2. Multi-Head Weighing & Distribution

Each weighing head operates independently for precise weight control. Multi-material blending can also be achieved to ensure uniform mixture.

Weighing data is fed back to the PLC system in real time, enabling dynamic adjustments during high-speed production.

3. Filling Mode Selection

Filling mode is selected according to material characteristics—gravity, vacuum, piston, or flow meter—ensuring precise delivery even during high-speed operation while minimizing dust and waste.

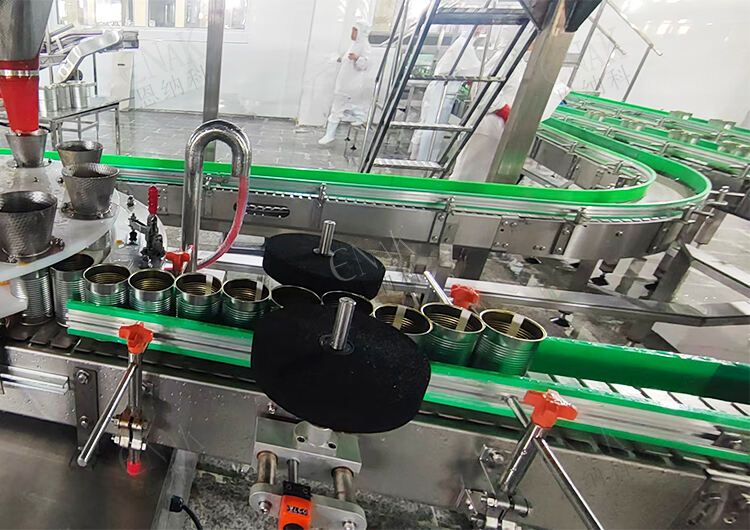

4. Packaging Output & Auxiliary Operations

Filled materials are conveyed to downstream packaging equipment. The system can be integrated with automatic sealing, labeling, weight inspection, and palletizing equipment to form a fully automated production line.

Multi-mode filling and multi-head synchronization ensure high throughput while maintaining filling precision.

5. Cleaning & Maintenance

Quick-release components and modular design facilitate cleaning and maintenance, complying with food and pharmaceutical hygiene standards, reducing downtime, and improving machine utilization.

Optional CIP/SIP online cleaning system ensures fast removal of residual materials and safe multi-product production.

Frequently Asked Questions

Q1: What is the filling accuracy?

A1: The multi-head scale filling machine provides high precision, typically within ±0.5% per package.

Q2: What types of materials are suitable?

A2: Powders, granules, grains, seasonings, dairy powders, and pharmaceutical powders.

Q3: Can the filling modes be switched?

A3: Yes, the machine can freely switch between gravity, vacuum, piston, and flow meter modes depending on material characteristics.

Q4: Is the operation complicated?

A4: Operation is simple via PLC and HMI, enabling settings, monitoring, and parameter adjustment with ease.

Q5: What safety measures are in place?

A5: Equipped with emergency stop buttons, protective doors, and multiple sensors to ensure operator and equipment safety.

Q6: What after-sales services are provided?

A6: Comprehensive technical support, on-site installation and commissioning, and remote guidance to ensure long-term stable operation.

If you are looking for a high-precision, high-efficiency, and versatile Automatic Solids Multi-Head Scale Filling Machine, Tianjin ENAK Machinery Co., Ltd is your trusted partner.

Contact us to request technical information and quotations. Submit your requirements, and we will design the most suitable production solution to help you upgrade and automate your production line.