Description

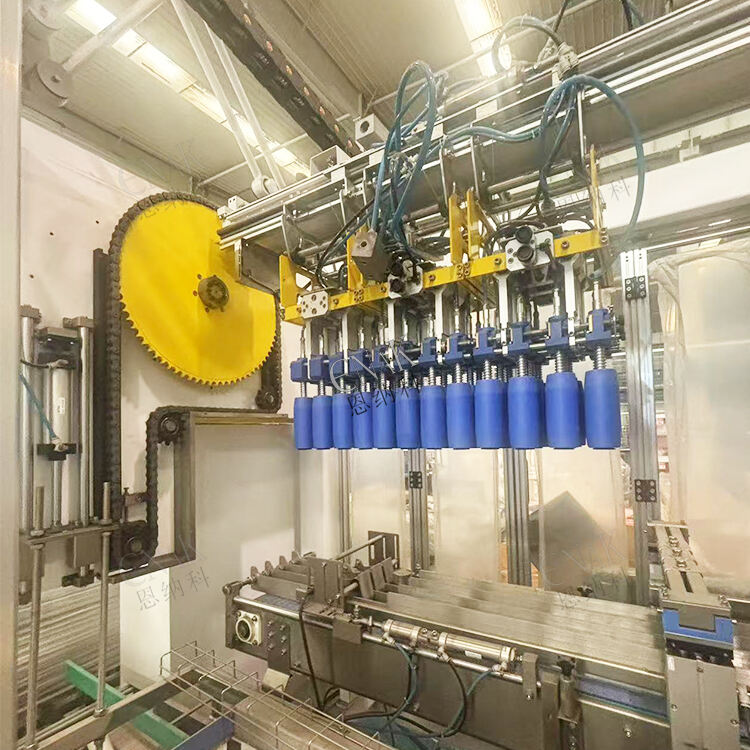

Product Overview & Adaptation Scope:

The Food Can Carton Case Packer is an automated device specifically designed for food packaging scenarios. It features strong compatibility, capable of adapting to various packaging formats such as PE bottles (e.g., sauce bottles), glass bottles (e.g., jam jars), small cartons (e.g., combined snack boxes), paper boxes (e.g., instant canned food boxes), and tinplate cans (e.g., meat cans, beverage cans). It covers the carton packing needs of most canned and bottled products in the food industry, eliminating the need for frequent replacement of core components and reducing the equipment investment cost for enterprises.

Product Performance & Operation Advantages:

The Food Can Carton Case Packer operates in an automated mode, with parameter settings completed via a human-machine interface. The operation process is simple and easy to understand, allowing new employees to work independently after 1-2 days of training. During the packing process, the alignment error of products is ≤1mm, ensuring a neat and uniform appearance that meets the standardization requirements of food packaging. Meanwhile, all parts of the Food Can Carton Case Packer that come into contact with products are made of 304 stainless steel, with no oil stains or dust pollution. It is easy to clean after operation, complying with the hygiene standards of the food industry and maintaining a clean production environment.

| Parameter Item | Parameter Value |

| Production Capacity | 12 - 40 cases/minute |

| Bottle Handling System | 2000 mm (Customizable according to customer site) |

| Bottle Dimensions | Diameter (55-130) * Height (140-335) mm |

| Carton Dimensions | Length (50-400) * Width (50-350) * Height (50-350) mm |

| Power Supply | 3-Phase; 380V; 50Hz (or customized as required) |

| Power Consumption | 5 kW |

| Number of Gripping Heads | Customized |

| Compressed Air | 0.8 - 1 m鲁/min (Pressure: 6 bar / 0.6 MPa) |

| Overall Dimensions | Length 6700 * Width 2140 * Height 3010 mm |

| Equipment Weight | 2000 kg |

Product Advantages

Durable Transmission Structure, Extending Equipment Service Life:

The core transmission system of the Food Can Carton Case Packer adopts a combined design of high-precision gears and imported bearings. The gear surfaces undergo carburizing and quenching treatment, with a hardness of HRC58-62, making their wear resistance twice that of ordinary gears. The bearings are from the Japanese NSK brand, featuring wear resistance and corrosion resistance, and can operate stably within a temperature range of -10℃ to 60℃. The transmission structure is also equipped with an automatic lubrication system, which injects food-grade lubricating oil into key components at fixed times and quantities to reduce mechanical friction and wear. Tests show that the mean time between failures (MTBF) of the Food Can Carton Case Packer reaches over 8,000 hours, with a service life of 8-10 years, 30% longer than similar equipment, reducing the frequency of equipment replacement and maintenance costs for enterprises.

High-Strength Frame, Enhancing Shockproof and Stable Performance:

The frame of the Food Can Carton Case Packer is integrally welded with Q235 cold-rolled steel plates, with a plate thickness of 8mm. The welded joints are inspected by ultrasonic flaw detection, ensuring no false welding or missing welding. The overall load-bearing capacity of the frame is 3,000kg, which can withstand the inertial impact force generated when the equipment operates at high speed. At the same time, the bottom of the frame is equipped with shock-absorbing foot pads made of nitrile rubber, with a shock absorption coefficient of 0.8. These foot pads can effectively absorb the vibration generated during the operation of the Food Can Carton Case Packer (the vibration amplitude during operation is ≤0.5mm), avoiding component loosening or product displacement caused by vibration. Even in complex workshop environments where multiple devices operate simultaneously, it can still maintain stable packing accuracy, ensuring that each carton of products is neatly arranged without collision damage.

Safety Protection Design, Complying with CE Safety Standards:

The Food Can Carton Case Packer strictly follows the requirements of EU CE safety certification and builds a multi-layer safety protection system. Firstly, it is equipped with a safety light curtain. When a human limb enters the moving area of the equipment, the Food Can Carton Case Packer can emergency stop within 0.1 seconds, with a response speed far exceeding the industry average. Secondly, all moving parts are equipped with protective covers made of transparent PC material, which not only do not affect the operator's observation of the equipment's operation status but also prevent safety accidents caused by foreign objects being involved or components falling off. Thirdly, it has built-in overload protection and short-circuit protection functions. When the equipment load exceeds the rated range or the circuit is abnormal, it will automatically cut off the power supply and trigger an audio-visual alarm, avoiding the risk of equipment burnout or personal electric shock, and fully ensuring the safety of operators and equipment.

Product Operation Guide

Preparation Before Startup :

First, check the appearance of the Food Can Carton Case Packer to ensure the frame is not deformed and the protective covers are not damaged. Second, check the oil level of the transmission components; if it is lower than the scale line, add food-grade lubricating oil. Third, check whether the power supply (three-phase 380V) and air source (0.6-0.8mpa) connections are normal to ensure no looseness or air leakage. Finally, perform a startup self-inspection through the human-machine interface; the system will automatically detect the status of the safety light curtain, transmission system, and grabbing mechanism, and enter the standby mode after the self-inspection is passed.

Parameter Setting & Operation :

According to the specifications of the products to be packed (e.g., diameter and height of tinplate cans) and the carton size (length, width, height), input the corresponding parameters into the human-machine interface. The system will automatically match the grabbing trajectory and packing speed (adjustable within the range of 10-20 cartons per minute). After the parameter setting is completed, place empty cartons into the carton feeding mechanism, pour the products to be packed into the feeding hopper, and press the "Auto Run" button to start the Food Can Carton Case Packer. No manual intervention is required throughout the process; the operator only needs to observe the operation status on the monitoring interface.

Shutdown & Cleaning :

After the production task is completed, press the "Stop" button. After the Food Can Carton Case Packer finishes packing the remaining products and resets, cut off the power supply and air source. Then, wipe the surface of the equipment with clean water, focusing on cleaning the grabbing mechanism and conveying track that come into contact with products. If there is food residue, clean it with a neutral detergent to avoid residue corrosion on components. Finally, check whether all parts of the equipment are intact, record the operation data (e.g., packing quantity, number of failures), and prepare for the next startup.

Frequently Asked Questions

Q1: Can the Food Can Carton Case Packer adapt to tinplate cans of different heights?

A1: Yes. The grabbing mechanism height of the Food Can Carton Case Packer supports stepless adjustment within 100-300mm. You only need to input the can height parameters into the human-machine interface, and the system will automatically adjust the lifting stroke of the grabbing claws without replacing mechanical components. The adaptation process takes only 2 minutes, which can meet the packing needs of tinplate cans of different specifications (50g-500g).

Q2: Is the Food Can Carton Case Packer noisy during operation? Will it affect the workshop environment?

A2: The noise of the Food Can Carton Case Packer during operation is ≤70 decibels, complying with the industrial workshop noise standard (≤85 decibels) and 10-15 decibels lower than similar equipment. The noise mainly comes from the transmission system. Through the dual noise reduction design of shock-absorbing foot pads and protective covers, the noise transmission can be further reduced, and it will not interfere with the work of workshop operators or the surrounding environment.

Q3: If the Food Can Carton Case Packer breaks down and the enterprise has no professional maintenance personnel, what should be done?

A3: We provide 7×24-hour online after-sales support. Enterprises can obtain technical guidance through phone calls or video calls, and more than 90% of minor faults can be resolved within 1 hour. If on-site maintenance is required, we have 6 after-sales service outlets nationwide. Engineers can provide on-site services within 24 hours in provincial capital cities and 48 hours in prefecture-level cities. At the same time, we provide emergency solutions for spare parts to minimize downtime.

If you have further questions about the quotation, customization needs (e.g., adaptation to special-specification products), or on-site test run arrangement of the Food Can Carton Case Packer, please leave your company name, contact information, and product details. Our professional sales team will contact you within 24 hours and provide you with a customized solution to help you improve the efficiency and quality of food can carton packing!