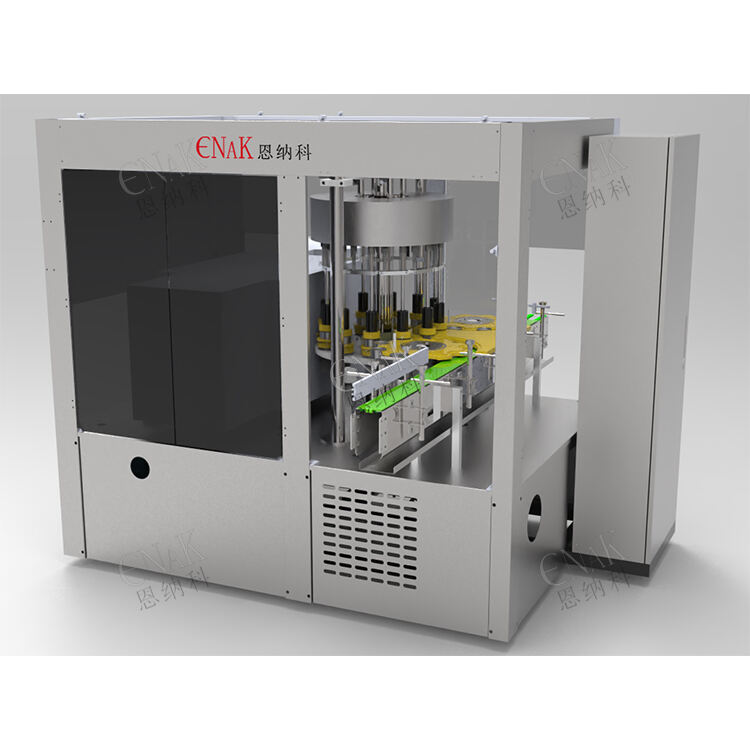

Description

The machine processes containers via a buffer-guided entry into star wheels, presses containers into position, applies labels with rotation-assisted smoothing, and exits labeled products. Designed for high-speed, high-precision labeling on two-piece cans (e.g., pet food cans), it resolves industry pain points such as slow paper label application and material waste. Features include: HMI-controlled operation for easy management. Reduced labor intensity and material waste. Enhanced product quality and automation.

Equipment Components

Encoders: SICK high-precision

Servo motors/drives: Inovance high-power systems.

PLC: EtherCAT controller.

HMI: Delta touchscreen.

Sensors: Panasonic color mark, SICK photoelectric

Pneumatics: Airtac, MAC, Taiwanese high-pressure blower.

Main motor/frequency converter: Inovance.

Correction device:Shanghai Zeyu

Low voltage components: festo, schneider

Pneumatic components: Yadeke, MAC, Taiwan high-pressure fan

Encoder: German SICK high-speed high-precision encoder

Mechanical Structure

Hot melt glue machine: independently developed glue box

Bracket: Stainless steel, universal casters, anchor bolts

Spindle: The main materials used are cast aluminum and cast stainless steel, with a high-performance 40Cr core shaft;

Conveyor system: The entire system adopts standard chain plate width, which can be flexibly connected for docking and wiring;

Star Wheel Component: Smooth transfer of products from the conveyor line to the spindle

Station lifting adjustment system: flexible for attaching labels to bottles at different heights

Labeling Station System: A labeling system that integrates unwinding, label driving, label cutting, gluing, and labeling rollers

Product Testing Switch Adjustment System

Stainless steel control box, waterproof button, emergency stop switch

Technical Specifications

| Category | Specification Item | Details |

| Capacity & Design | Number of Workstations | 12 |

| Special Design | Vacuum drum (4 stations), Cutter roller (2 stations), Bottle holder (12 stations), Standard labeling station | |

| Production Speed | Up to 18,000 BPH (Bottles Per Hour) | |

| Speed depends on bottle shape and label material. | ||

| Speed Adjustment Method | Continuously Variable Transmission | |

| Power & Utilities | Power Supply | AC380V, 50Hz |

| Total Power / Operating Power | 13 KW / 7 KW (normal operation) | |

| Wiring System | Three-Phase Five-Wire System (L1, L2, L3, N, PE) | |

| Air Source Requirement | 5 Kg/cm² | |

| Performance & Dimensions | Labeling Accuracy | ± 1 mm |

| Requires product size error within ± 0.3 mm. The labeling position should be 4 mm wider than the label. | ||

| Applicable Product Size | Diameter ≤ φ95 mm (Round or square bottles, etc.) | |

| Non-standard sizes can be customized. | ||

| Machine Dimensions (L×W×H) | 2600 mm (Tabletop 2013 mm) × 1486 mm × 2000 mm | |

| Weight | 5000 kg | |

| Label & Gluing System | Label Core Inner Diameter | φ150 mm |

| Maximum Label Diameter | φ480 mm | |

| Label Height Range | H20 mm (Min) to H130 mm (Max) | |

| Glue Application Method | Roll glue method (applied on both ends of the label) | |

| Label Colloid (Adhesive) | Henkel EM362 hot melt or equivalent performance hot melt adhesive | |

| Glue Temperature Range | 120 - 160 °C | |

| Label Type | OPP, Pearl Film, Paper-Plastic Composite Film, Paper Label | |

| Label Thickness | 0.035 - 0.045 mm |

Structural Advantages

1. Automated Operation & Intelligent Detection

Automatic Start/Stop: A photoelectric switch automatically detects bottle entry, enabling intelligent label dispensing and fully automated equipment operation.

Label Detection: Equipped with a label detection function and a "no label" alarm to prevent unlabeled products.

High-Precision Sensing: The product detection sensor utilizes a high-speed German SICK photoelectric eye for accurate and reliable detection.

Easy Adjustment: A dedicated product detection switch adjustment bracket allows for quick and easy modification of the detection point.

2. Efficient Label Handling & Application System

Precision Label Feeding: The label drive roller actively feeds labels controlled by an encoder and photoelectric signals, featuring automatic label tensioning.

Pre-cutting & Transfer: Labels are pre-cut using single or double disc cutters and transferred to the pre-labeling position via a vacuum drum.

Smooth Application: A combination of brushes supports the label, ensuring it is smoothly and seamlessly applied to the bottle surface without bubbles.

High-Speed & Stability: The labeling system employs continuous motion labeling for faster and more stable operation.

3. Durable Construction & Easy Maintenance

Intelligent Lubrication: The entire machine features an intelligent oil lubrication system, ensuring efficient transmission and a longer service life for components like bearings.

High-Quality Materials: Constructed with an all-stainless steel frame, offering a clean, elegant appearance and durable, long-lasting performance.

Quick Changeover: The bottle screw and star wheel incorporate a quick-release design concept, significantly reducing time spent on product changeovers.

Wide Compatibility: Capable of labeling both square and round bottles (utilizing cams, synchronous belts, and servo motors for different application methods).