Description

The Canned Tin Labeling Machine developed by Tianjin ENAK is an advanced automatic labeling solution designed for high-efficiency production lines. It is widely applied in food, beverage, seasoning, and chemical industries, providing precise and stable labeling performance for various sizes of tin cans.

Key Features:

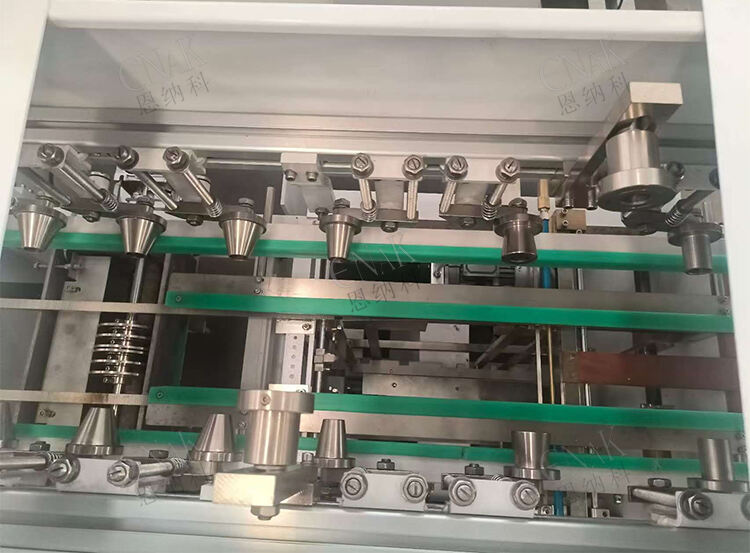

Robust Frame Structure – The machine frame adopts 5.0mm thick carbon steel plates with angle welding and painted surface. It ensures durability and stability for long-term operation.

Labeling Conveyor System – The modular chain plate structure is made of SUS304 stainless steel, with reinforced bending and welding to guarantee smooth and steady transportation.

Supportive Carrier Frame – The machine adopts SUS304 stainless steel square tube welding (60×60×2.0mm), with mounted bearings, SUS304 screws, and a worm gear reducer motor (P=0.55/0.75KW). This provides powerful and consistent performance.

Premium Material Selection – The main frame uses SS41 (A3 painted steel), transmission shafts are made of S45C bearing steel, while contact surfaces and conveyors use 304 stainless steel with high-molecular wear strips. This ensures reduced friction, corrosion resistance, and long lifespan.

The Canned Tin Labeling Machine is not only compact and user-friendly but also highly adaptable to different can types. It helps companies significantly reduce manual labor, improve efficiency, and optimize production line management.

English Name |

Quantity |

Front and Rear Turnover Cage |

1 set |

Glue Tank |

1 set |

Main Machine |

1 unit |

Control Cabinet (Operation Panel) |

1 unit |

Item |

Specification |

Standard Capacity |

50–400 cans/min (depends on can diameter) |

Operation Mode |

Button & knob |

Material Weight |

30G–4200G |

Motor Power Supply |

Three-phase five-wire, AC 380V/50HZ, 3KW per unit; 6KW for whole line |

Control Voltage |

DC 24V |

Air Consumption |

60NL/MIN (Air usage: 2–4KG/CM²) |

Air Pipe Interface |

φ8mm |

Machine Dimension |

ENKGD-01: (L)2300MM × (W)752MM × (H)1263MM |

Environmental Conditions |

Altitude: 3–2000m; Temperature: 0℃–40℃; Humidity: 40%–95% |

Machine Weight |

ENKG-01: 750KG; ENKGD-01: 900KG |

Label Size Range |

ENKGD-01 Max: 500×254mm; Min: 214×50mm |

Material Requirements |

1) Label adhesive: Hot melt glue + Quick-dry glue2) Line height: Inlet 1100–1200mm, Outlet 700–800mm3) Can diameter: ENKG-01: φ55–φ120mm; ENKGD-01: φ55–φ160mm |

Product Advantages

The Canned Tin Labeling Machine provides multiple advantages compared to traditional labeling equipment:

1. High-Quality Materials and Durability

The machine is built from stainless steel, aluminum alloy, engineering plastics, and coated carbon steel, all compliant with national standards. This guarantees strong resistance to corrosion, excellent durability, and long-term stability even in humid and demanding production environments.

2. Compact Structure and Space Saving

With a carefully designed compact body, the Canned Tin Labeling Machine requires less installation space. It simplifies the pre-labeling conveyor system, reducing the overall investment cost of a production line. For bulk buyers, this design means lower space usage and higher cost-efficiency.

3. Efficient Dual Label Supply System

The machine adopts a hydraulic cylinder label feeding method and is equipped with a dual-label supply mechanism. Labels can be alternated without stopping the machine, ensuring continuous production. (Note: not applicable for labels under 35mm width). This design ensures high efficiency and avoids downtime.

4. Smart Glue Application System

The tail-end glue supply is controlled by a photoelectric sensor. Glue is only applied when cans are present—“no can, no glue.” This saves glue consumption, lowers production costs, and reduces unnecessary waste, making the machine environmentally friendly.

5. Flexible Adjustment for Different Can Sizes

The Canned Tin Labeling Machine supports a wide range of tin can specifications. Changing can types is simple, requires fewer spare parts, and can be done quickly, making it ideal for factories producing multiple product lines.

6. Reduced Wear and Longer Service Life

The parts that come into contact with cans are fitted with high-molecular wear strips, which greatly reduce friction damage to tin cans. This ensures high product quality, minimizes can loss, and extends the lifespan of the machine.

7. Strong Label Adhesion with Lower Cost

For two-piece cans, an extra glue point is added to ensure stronger adhesion of the label tail. Meanwhile, glue is only applied to both ends of the label, which reduces glue usage and significantly lowers labeling costs.

8. Reliable Components with Stable Operation

95% of the electrical components are from internationally renowned brands. This ensures stable performance, efficient operation, and significant labor savings for buyers.

9. Low Noise, International Standards

The Canned Tin Labeling Machine operates at noise levels below 75dB, complying with international standards for safety and environmental requirements, and providing a more comfortable working environment.

In short, the Canned Tin Labeling Machine delivers strong performance, reduced costs, and eco-friendly benefits—helping businesses gain a competitive edge in modern production.

Production Process

The Canned Tin Labeling Machine operates through a fully automated process, ensuring precision and efficiency:

Automatic Feeding – Cans can be manually loaded or automatically fed by a de-palletizer. They are arranged into a single row by the rotary table and delivered to the belt elevator.

Coding Step – Cans pass through the elevator section for coding, ensuring traceability.

Can Rolling and Labeling – After passing through the turnover system, cans roll into the machine. A pressing belt ensures can rotation while hot melt glue is applied. The front end of the label adheres to the glued surface, wrapping around the can. The tail end glue mechanism applies glue for secure closure.

Finished Output – After labeling, the cans are rolled out of the machine by the conveyor system, flipped again, and moved to the receiving line. The machine can be connected to automatic packing and palletizing equipment for a fully integrated production line.

The Canned Tin Labeling Machine ensures stable, continuous, and high-speed operation while minimizing manual intervention and maximizing productivity.

FAQ

Q1: Can the Canned Tin Labeling Machine handle different tin can sizes?

Yes. The machine is designed for flexibility. Adjustments can be made quickly and require fewer replacement parts, making it suitable for multiple can types.

Q2: How strong is the labeling adhesion?

The machine uses a combination of hot melt glue and quick-dry glue. It ensures firm adhesion at both label ends, reducing the risk of detachment.

Q3: Is the Canned Tin Labeling Machine environmentally friendly?

Yes. With intelligent glue application and low glue usage, it minimizes waste and reduces labeling costs, supporting eco-friendly production.

Q4: Does the machine produce high noise during operation?

No. The machine’s noise level is below 75dB, which complies with international noise standards, ensuring a quieter workplace.

Q5: Can it integrate with an automatic production line?

Absolutely. The Canned Tin Labeling Machine can connect with upstream and downstream equipment such as de-palletizers, case packers, and palletizers for full automation.

The Canned Tin Labeling Machine from Tianjin ENAK offers durability, cost savings, flexibility, and eco-friendly operation. Designed with premium materials, smart systems, and global-standard performance, it is the perfect choice for industries that rely on tin can packaging.

If you are looking for a reliable and efficient Canned Tin Labeling Machine for your production line, contact us today. Leave your inquiry below, and our professional team will provide customized solutions, technical support, and competitive quotations tailored to your needs.