Customer Background

In today’s competitive manufacturing landscape, packaging has become more than a simple end-of-line activity. For many companies, it directly affects operational efficiency, product safety, and overall market competitiveness. One of our clients, a mid-sized manufacturer with a broad portfolio of food and beverage products, faced constant challenges in meeting the dynamic needs of their customers. Product varieties included different bottle shapes, pouch packs, and cartons of varying sizes. This variety demanded a packaging solution that could handle diverse formats without requiring lengthy downtime for changeovers.

As the production supervisor overseeing several high-output lines, I understood the importance of ensuring smooth, consistent performance. Manual packaging had previously slowed the lines and increased labor costs, while older machinery struggled with the flexibility required by current production demands. The company needed a solution that could integrate seamlessly into existing workflows, maintain production speed, and allow for frequent changes in packaging formats.

The decision to introduce a carton case packer was based on industry benchmarks and third-party research indicating that automated case packing can improve packaging line efficiency by 20–30% on average. A reliable carton case packer not only reduces manual handling but also ensures uniformity and stability of packed products, critical in industries where presentation and structural integrity matter.

After careful evaluation, the Tianjin ENAK carton case packer was selected to modernize the client’s production line. The aim was to increase throughput, improve packaging flexibility, and align operations with industry best practices.

Product Features

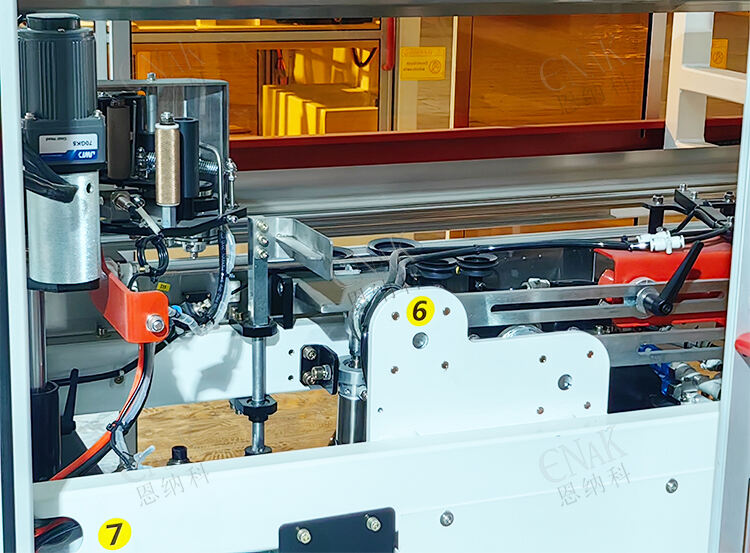

The carton case packer provided by Tianjin ENAK addressed the client’s needs with several distinct features. First, the system offers flexible packaging modes, capable of arranging products for vertical or horizontal case packing. This feature is essential when dealing with fragile items like glass bottles or pouch packs that require careful positioning to avoid damage. For sturdier items, horizontal packing maximizes space utilization and ensures efficient logistics handling.

Second, the carton case packer integrates carton forming, loading, and sealing in a single streamlined unit. By eliminating the need for separate machines, it simplifies line management and minimizes equipment footprint. This integration significantly reduced manual interventions, contributing to lower error rates and reduced downtime.

Another critical feature is the machine’s compatibility with cartons of different dimensions. Manufacturers often face fluctuating orders requiring small, medium, and large case sizes. The carton case packer can adjust to these variations quickly, with simplified changeover mechanisms that require minimal training. Operators can now switch between carton sizes within minutes, rather than hours, ensuring continuous flow and maximizing productivity.

Finally, the equipment is highly adaptable to different industries. Whether in food, beverage, or chemical manufacturing, the carton case packer provides the stability and reliability required to handle both lightweight and heavy-duty products. The ability to maintain consistent sealing quality further guarantees that products remain secure during storage and transportation.

By combining flexibility, integration, and reliability, the carton case packer offered a tailored solution that aligned perfectly with the client’s operational requirements.

Production Process

The integration of the carton case packer into the client’s production lines followed a structured approach. The first step involved analyzing existing workflows to determine where automation would have the most impact. Previously, manual case packing required up to six workers per line, creating inconsistencies in speed and accuracy. The new carton case packer replaced these manual tasks with automated precision.

During carton forming, the system automatically erected flat cartons into stable shapes, reducing the need for manual assembly. Once formed, cartons moved directly into the loading stage, where products were grouped and packed according to pre-set configurations. The carton case packer allowed vertical or horizontal orientation depending on product type. For example, bottled beverages were loaded vertically to prevent leakage risks, while packaged powders were positioned horizontally to maximize stacking efficiency.

The adaptability of the carton case packer became evident when order requirements changed mid-shift. Operators were able to adjust carton dimensions and packing orientations through the intuitive control interface without significant downtime. This capability ensured that production could continue smoothly despite fluctuating demands.

Following product loading, cartons were sealed using reinforced methods that ensured tamper resistance and shipment durability. The sealed cartons then proceeded to palletizing stations, ready for distribution.

From a production supervisor’s perspective, the most impressive aspect was the system’s stability. Across multiple shifts, the carton case packer maintained consistent speed and quality with minimal unplanned stoppages. Maintenance routines were simplified by the machine’s fault self-diagnosis system, which alerted operators to minor issues before they escalated. This predictive approach to maintenance reduced downtime by approximately 15%, according to internal line reports.

Integration with food and chemical lines also demonstrated the versatility of the carton case packer. In the food sector, where hygiene is critical, the machine’s design minimized dust accumulation and allowed for easy cleaning. In the chemical sector, handling heavier products required precise load balancing, which the packer managed effectively.

Overall, the implementation of the carton case packer transformed the production process from labor-intensive manual handling to an automated, streamlined operation, enabling the company to maintain consistent performance even under fluctuating demands.

Results and Feedback

The results following the deployment of the carton case packer were both measurable and transformative. Production capacity increased significantly, with throughput rising by nearly 25%. This improvement directly correlated with reduced reliance on manual labor, enabling the company to redeploy workers to higher-value tasks rather than repetitive packaging work.

Line flexibility also improved. The ability to handle diverse carton sizes and orientations allowed the company to accept more customized orders from clients without worrying about operational delays. This flexibility positioned the business more competitively in the market, especially in sectors like food and beverage, where product variety is high.

Feedback from operators was positive. They appreciated the user-friendly interface and reduced physical strain associated with manual packaging. Supervisory teams also noted fewer errors in final packaging, lowering the rate of rework and returns.

From a cost perspective, savings were realized not only through labor reduction but also through more efficient use of packaging materials. The consistent performance of the carton case packer reduced material waste, ensuring cartons were packed securely with minimal excess.

Third-party studies have indicated that companies implementing advanced carton case packer solutions often achieve payback on investment within 18–24 months, a finding consistent with the client’s experience. The success of this project underscores the value of modern packaging automation in improving both short-term productivity and long-term competitiveness.