Customer Background

As a project manager overseeing high-volume beverage and consumer goods packaging, I have observed that operational efficiency and line flexibility are critical drivers for modern production facilities. Our client, a mid-sized manufacturing company specializing in packaged beverages, faced increasing demand for short-run production of multiple product variants. Seasonal promotions, new product launches, and frequent order changes required the packaging line to adapt quickly without compromising throughput or quality.

Historically, the company relied on manual carton forming and semi-automatic systems, which created bottlenecks during peak periods. Manual labor costs were high, error rates increased with product variety, and downtime during carton changeovers affected overall line efficiency. Additionally, frequent adjustments to accommodate different carton sizes often led to production delays, increased waste, and a higher risk of mechanical failures due to misalignment or improper handling.

The company sought solutions that could improve automation, reduce labor dependency, and enhance overall line flexibility. Beyond simple automation, the project required equipment capable of integrating seamlessly with upstream and downstream processes, maintaining high operational stability, and adapting quickly to different carton dimensions. The ideal solution would also support predictive maintenance, minimizing unplanned downtime and ensuring consistent performance across multiple production lines.

After a careful evaluation of available equipment, Tianjin ENAK’s automatic carton erector emerged as a suitable candidate. Its combination of stable operation, compatibility with various carton sizes, and rapid adjustment features made it an attractive choice for our client. Moreover, the system’s PLC-based control and modular design promised to improve workflow efficiency, streamline maintenance, and provide a reliable platform for future line expansions.

Project Requirements and Product Features

The project team outlined several core requirements for the packaging line upgrade. First, the automatic carton erector needed to achieve high-speed carton forming while maintaining consistent quality. Previous systems exhibited misfeeds, jams, and misaligned cartons, leading to interruptions in downstream processes. Second, compatibility with multiple carton sizes was essential to accommodate seasonal packaging variations and promotional packs. Third, the equipment had to be user-friendly, with quick-change settings to reduce downtime during format switches.

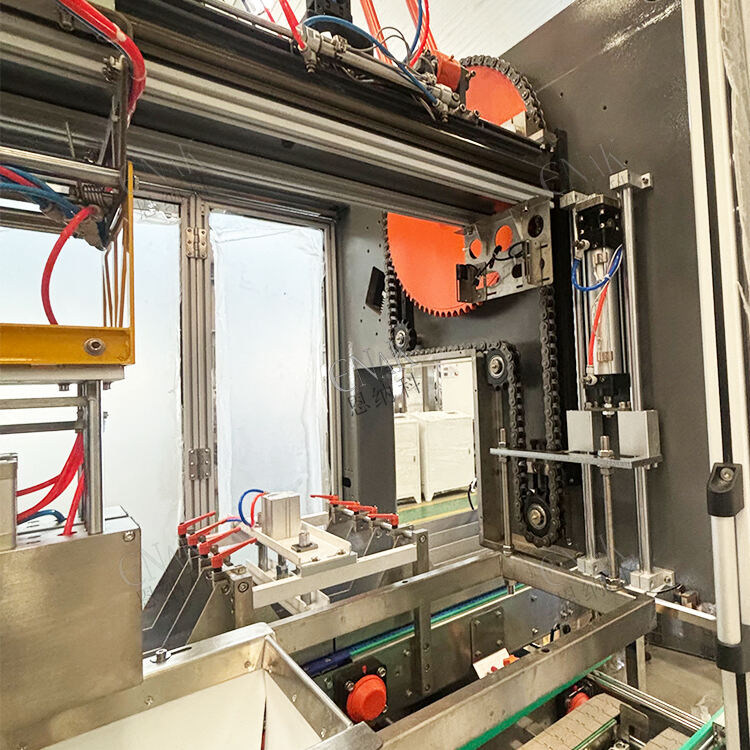

Tianjin ENAK’s automatic carton erector directly addressed these needs. Its robust mechanical design ensures stable operation under continuous production, with low failure rates even during extended 24/7 operation. High-strength structural components, precision servo mechanisms, and reliable sensors work together to minimize errors in carton handling and forming. The system’s compatibility with multiple carton dimensions allows production engineers to switch between sizes without lengthy manual adjustments. Adjustable guides, modular feed trays, and programmable PLC controls simplify the process, reducing changeover times significantly.

Another critical feature is the quick adjustment capability. The machine enables rapid format changes, allowing operators to switch between small, medium, and large carton sizes in minimal time. This flexibility supports production schedules with high SKU diversity, reduces waste, and ensures that customer delivery timelines are met. Additionally, the automatic carton erector is designed to integrate with existing conveyors, filling machines, and sealing equipment, ensuring a seamless workflow across the packaging line.

Operational stability and reliability are further enhanced through predictive maintenance features. Sensors monitor key performance parameters such as motor load, feed alignment, and carton detection, alerting operators to potential issues before failures occur. This proactive approach minimizes unplanned downtime and keeps production consistent, contributing to improved overall equipment effectiveness (OEE).

In summary, the project requirements emphasized efficiency, flexibility, and reliability, all of which are core strengths of Tianjin ENAK’s automatic carton erector. Its combination of stable operation, multi-size compatibility, and rapid adjustment ensures that production lines remain responsive to market demands without sacrificing quality or throughput.

Product Application Process

The implementation of the automatic carton erector involved several structured steps to ensure smooth integration into the existing production line. The first phase was line assessment and preparation. Production engineers conducted detailed analyses of the existing workflow, identifying bottlenecks, compatibility issues, and points where automation could deliver the greatest efficiency gains. The modular design of ENAK’s automatic carton erector allowed the team to simulate integration without major alterations to upstream and downstream equipment.

Installation followed with careful alignment of feed trays, guides, and conveyors to match the operational footprint of the line. The automatic carton erector’s PLC control system was configured to synchronize with upstream filling and labeling machines, ensuring that cartons were formed and delivered at a consistent pace to prevent accumulation or delays. During the setup, sensors and safety interlocks were tested to guarantee proper operation, particularly under high-speed conditions.

Operational trials demonstrated the system’s effectiveness in handling multiple carton sizes. Operators performed repeated changeovers to verify ease of adjustment and confirm that the machine could accommodate different product formats without causing jams or misfeeds. The rapid adjustment feature allowed size changes in under 10 minutes, a significant improvement over previous systems that required manual reconfiguration and downtime of up to an hour.

During full-scale operation, the automatic carton erector’s impact on line performance was immediately evident. Cartons were consistently formed with precise alignment, reducing errors in downstream filling and sealing processes. The stability of the system minimized jams and misfeeds, which previously caused interruptions and required manual intervention. Additionally, the integration with the conveyor system ensured smooth transfer of cartons across the packaging line, reducing collisions and product damage.

Maintenance procedures were simplified thanks to modular components and accessible service points. Operators could perform routine checks, lubrication, and part replacements without stopping the entire line, enhancing uptime and reducing labor costs. Predictive maintenance alerts also contributed to proactive management, helping the team identify components nearing wear thresholds and schedule timely replacements.

Throughout the application process, the automatic carton erector demonstrated not only operational reliability but also flexibility in handling various carton formats. Its compatibility with small, medium, and large boxes allowed production planners to adapt quickly to customer orders and seasonal demands, supporting a dynamic and responsive packaging environment.

Results and Achievements

After several months of operation, the benefits of Tianjin ENAK’s automatic carton erector became clear. Production line flexibility improved significantly, allowing the facility to handle a greater variety of carton sizes with minimal downtime. Changeover times were reduced by over 70%, enabling faster response to market demands and short-run production schedules.

Operational stability was markedly enhanced. The low failure rate and robust mechanical design minimized disruptions, improving overall equipment effectiveness (OEE) and reducing labor requirements for troubleshooting and manual interventions. Smooth carton handling and precise forming decreased the incidence of misaligned cartons and product damage, resulting in reduced waste and higher quality output.

From a managerial perspective, the automatic carton erector contributed to strategic goals such as operational efficiency, cost control, and production agility. Its rapid format adjustments and multi-size compatibility allowed the company to optimize packaging lines without additional capital expenditure on separate machines. Predictive maintenance features further strengthened long-term reliability, reducing unplanned downtime and associated operational risks.

In conclusion, Tianjin ENAK’s automatic carton erector delivered measurable improvements in packaging line flexibility, efficiency, and reliability. By integrating this system, the facility achieved a high level of automation, reduced labor dependency, and enhanced the capacity to respond to diverse production requirements. This case exemplifies how well-engineered automation solutions can transform packaging operations, offering both immediate operational benefits and long-term strategic advantages.