Description

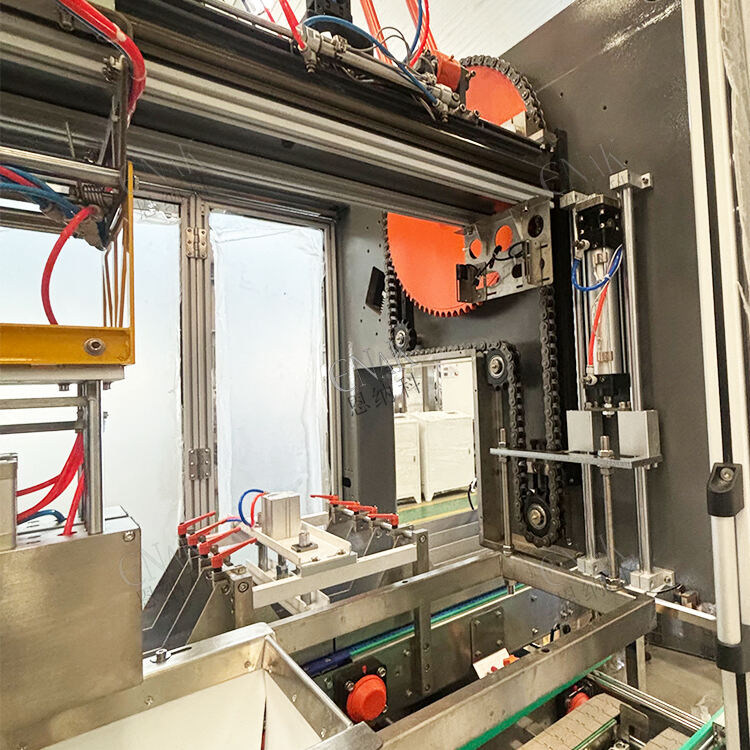

Product Overview & Core Features:

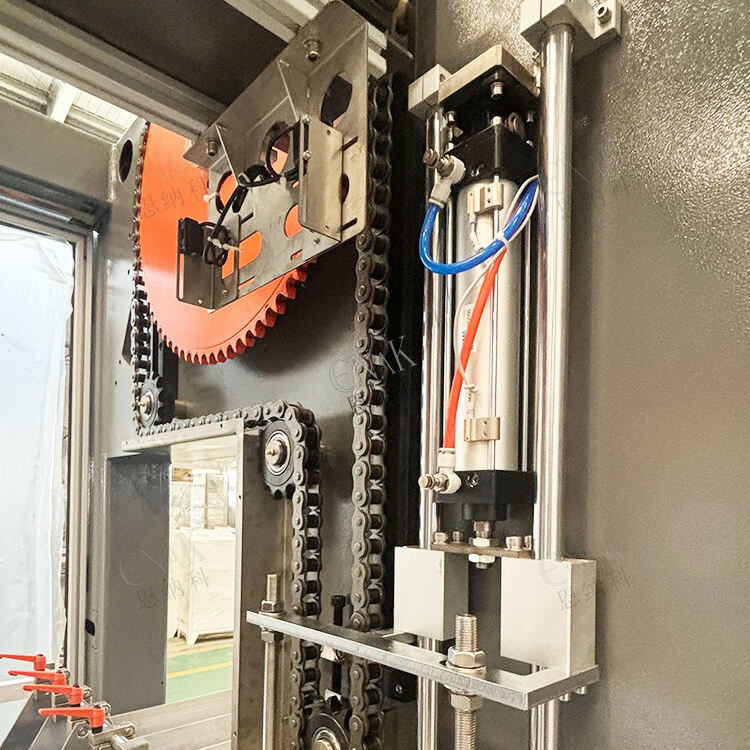

The Automatic Case Packer Machine adopts a co-directional design for bottle infeed and carton infeed, breaking the efficiency bottleneck of traditional opposite-direction conveying and realizing synchronous flow of products and cartons. The equipment integrates core functions: multi-lane counting can accurately count the number of products in each lane with an error ≤ 0.1%; multi-lane bottle stopping can temporarily stop products according to the case packing rhythm to avoid congestion; the bottle grabbing position is equipped with pressure positioning detection and metering functions, which adjust the grabbing force in real time to ensure stable product handling.

Performance & Safety Guarantee:

The electrical control system is equipped with a safety light curtain photoelectric detection device. When a human body or foreign object enters the dangerous area of the equipment, it can trigger a shutdown within 0.1 seconds, forming multiple safety protections, which fully complies with the national standard GB/T 19891-2021 "Mechanical Safety - Hygienic Requirements for Mechanical Design". Aiming at the pain point of easy deformation of soft bottles (such as plastic squeeze bottles and hoses), the equipment realizes damage-free case packing through the design of flexible grippers and buffer mechanisms, solving the problem that traditional equipment has difficulty handling soft containers.

Operation & Adaptation Advantages:

The operation process of the Automatic Case Packer Machine is simplified. Parameter setting can be completed through a 7-inch human-machine interface without professional technicians; it also has strong compatibility, which can quickly switch to adapt to products of different specifications to meet the needs of multi-category production. During operation, there is no dust or oil pollution, maintaining a clean production environment.

| Parameter Item | Parameter Value |

| Production Capacity | 12 - 40 cases/minute |

| Bottle Handling System | 2000 mm (Customizable according to customer site) |

| Bottle Dimensions | Diameter (55-130) * Height (140-335) mm |

| Carton Dimensions | Length (50-400) * Width (50-350) * Height (50-350) mm |

| Power Supply | 3-Phase; 380V; 50Hz (or customized as required) |

| Power Consumption | 5 kW |

| Number of Gripping Heads | Customized |

| Compressed Air | 0.8 - 1 m/min (Pressure: 6 bar / 0.6 MPa) |

| Overall Dimensions | Length 6700 * Width 2140 * Height 3010 mm |

| Equipment Weight | 2000 kg |

Product Advantages

Co-directional Conveying + Intelligent Separate Control, Greatly Improving Production Efficiency:

Traditional case packers require additional steering mechanisms due to the different directions of bottle infeed and carton infeed, resulting in a 30% or more increase in conveying time. The co-directional conveying design of this Automatic Case Packer Machine eliminates the steering link, and with multi-lane counting and bottle stopping functions, it can realize 1-4 lanes of synchronous operation. Taking the case packing of 500ml PE bottles in the daily chemical industry as an example, it can complete 1000-1500 cases per hour, which is 40% more efficient than traditional equipment. Moreover, the counting accuracy can avoid customer complaints caused by quantity errors and reduce rework costs.

Flexible Grabbing Technology, Expanding the Product Adaptation Boundary:

Aiming at the problems of easy deformation of soft bottles and easy scratching of hard bottles, the Automatic Case Packer Machine adopts a dual-mode grabbing system: for soft bottles (such as cosmetic hoses and food squeeze bottles), it is equipped with food-grade silicone flexible grippers, and the grabbing force can be accurately adjusted between 0.3-5N to ensure that the bottle body is not deformed and no liquid leaks; for hard containers such as glass bottles and tin cans, a combined design of vacuum suction cups and mechanical positioning is adopted to avoid scratches on the bottle body. This flexible design enables the Automatic Case Packer Machine to be compatible with containers of different specifications (10ml-10L) and different materials, reducing the investment of enterprises in replacing equipment due to product iteration, and the adaptation cost is reduced by 50%.

Full-Dimensional Safety Protection, Reducing Operation Risks:

The safety light curtain photoelectric detection system covers all dangerous areas of the Automatic Case Packer Machine, with a response speed of 0.08 seconds, far exceeding the industry average of 0.2 seconds; at the same time, the equipment has built-in overload protection, short-circuit protection, material shortage alarm and other functions. When abnormalities such as bottle jamming and carton shortage occur, it will immediately shut down and trigger an audio-visual alarm to avoid equipment damage or product loss. In addition, the machine body is made of 304 stainless steel, and the surface is treated with electrolytic polishing, with no dead corners for cleaning, which meets the hygiene standards of the food and pharmaceutical industries and helps enterprises avoid regulatory penalties caused by unqualified hygiene.

Application Scenarios

Food and Beverage Industry:

The Automatic Case Packer Machine is suitable for case packing of PE bottled fruit juice, glass bottled yogurt, tin canned food and other products, and can realize high-speed and aseptic case packing. For example, in a fruit juice production line, the equipment can neatly pack labeled PE bottles in specifications of 6 bottles/group or 12 bottles/group, and cooperate with the front-end filling line to realize the whole-process automation, reducing manual contact, ensuring food hygiene and safety, and meeting the large-scale production demand of more than 100,000 cases per day.

Daily Chemical and Cosmetics Industry:

For products such as PE bottles of shampoo, skin care hoses, and special-shaped bottles of laundry detergent, the Automatic Case Packer Machine solves the problems of soft bottle deformation and difficult positioning of special-shaped bottles through flexible grippers and customized grabbing trajectories. In the case packing scenario of facial mask cartons, the equipment can accurately grab the cartons and place them in layers into the cartons, ensuring that the cartons are wrinkle-free and neatly arranged, improving the shelf display effect of products, and adapting to the multi-category and small-batch production characteristics of daily chemical enterprises.

Pharmaceutical and Health Industry:

The Automatic Case Packer Machine meets the requirements of GMP certification and can be used for aseptic case packing of pharmaceutical glass bottles, PE bottles of health products, and medical cartons. The noise of the equipment during operation is ≤ 65 decibels, meeting the mute standard of pharmaceutical workshops; the grabbing mechanism adopts a detachable and washable design, which is convenient for regular disinfection and sterilization to avoid cross-contamination, and is suitable for products with strict requirements on the production environment such as oral liquids and capsules.

Frequently Asked Questions

Q1: Can the Automatic Case Packer Machine be customized according to our carton size?

A1: Yes. The equipment supports stepless adjustment of carton sizes (length 180-650mm × width 150-450mm × height 80-350mm). If your carton size exceeds this range, we can customize it by replacing the conveying track and adjusting the stroke of the grabbing mechanism. The customization cycle is only 10-15 days, and no additional fees are charged for the customization of core components.

Q2: Soft bottles are easy to tip over after case packing. Does the equipment have a solution?

A2: Yes. Aiming at the problem of soft bottle tipping, the Automatic Case Packer Machine is designed with a double-layer positioning mechanism: first, an adjustable partition is preset in the carton to fix the product position; second, the grabbing mechanism adopts a "slow lowering with light pressure" mode when packing, placing the products stably between the partitions. At the same time, it supports the customization of anti-slip pallets to ensure that the soft bottles do not tip over or collide during transportation. Through testing, the tipping rate of products after case packing can be controlled below 0.1%.

Q3: What about the energy consumption and floor space of the Automatic Case Packer Machine? Is it suitable for small and medium-sized enterprises?

A3: The power of the equipment is only 6kW, and it automatically enters the low-power mode (energy consumption ≤ 1.2kW) when on standby. Calculated based on 8 hours of operation per day, the average daily power consumption is about 45 kWh, which is 20% lower than that of similar equipment. The floor space is 3.2m (length) × 1.8m (width), with high space utilization. It also supports docking with existing production lines without large-scale workshop transformation. Small and medium-sized enterprises can flexibly configure single-lane or double-lane operation modes according to output, and the investment cost is controllable.

If you have further needs for the quotation, customization plan, or on-site test run arrangement of the Automatic Case Packer Machine, please leave your company name, contact information, and product specification requirements. Our professional consultants will contact you within 24 hours and provide you with a tailor-made automatic case packing solution to help you improve production efficiency and reduce operating costs!