Description

Product Overview:

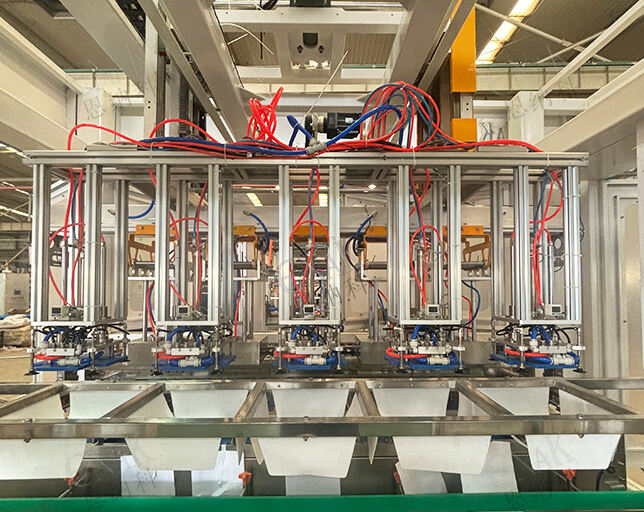

The Case Packer Electric Packaging Machines for Shampoo Packing Production Line is a truss-type case packing equipment. It can load sealed shampoo PE bottles, hoses, etc., into cartons or trays according to preset arrangements, supporting multiple packing forms (such as single-row, multi-row, and layered packing) to meet the packaging needs of different shampoo specifications. It helps the production line achieve automatic case packing and reduce manual intervention.

Product Performance:

Equipped with a PLC + touch screen control system, the machine’s visual operation interface enables quick parameter setting and grouping adjustment (e.g., 6 bottles/carton, 12 bottles/carton). New employees can master the operation after 1 hour of training. Designed with the concept of "high speed, stability, and space saving", it can achieve a packing speed of 10-20 cartons per minute during operation. With a compact body, it fits the limited layout of workshops. Meanwhile, it can reduce 3-4 manual labors, lower labor intensity, and improve the standardized management level of the production line.

Application Scope:

In addition to being core-adapted to shampoo packaging production lines, it can also be used for case packing of bottles and cans in industries such as water, beverages, canned foods, and daily chemicals (e.g., body wash, hair conditioner). It has strong compatibility and no need for frequent replacement of core components.

Product Advantages

High-Quality Materials & Safety Protection, Compliant with National Standards for Higher Reliability:

The main body of the Case Packer Electric Packaging Machines for Shampoo Packing Production Line is made of stainless steel (parts in contact with products), aluminum alloy (transmission structure), engineering plastics (protective shell), and carbon steel with spray plating (frame). The stainless steel material is corrosion-resistant and easy to clean, meeting the hygiene standards of the daily chemical industry. The lightweight design of aluminum alloy and engineering plastics reduces the equipment weight while ensuring structural strength. The spray plating treatment on carbon steel enhances the rust resistance of the frame and extends its service life. In addition, the equipment is equipped with fully enclosed safety guards and photoelectric sensors. It automatically stops when the human body approaches moving parts, fully complying with the national standard GB 12265.1-2007 "Mechanical Safety - Safety Distances to Prevent Upper Limbs from Reaching Hazardous Areas" and ensuring the safety of operators.

Side-In Bottle Design, Saving Space & Reducing Costs:

Adopting a side-in bottle design, compared with traditional front-in bottle equipment, the floor space is reduced by 40% (for standard specifications, the equipment only covers 2.5m × 3m), which can be flexibly integrated into the compact layout of the existing shampoo production line. At the same time, the side-in bottle design does not require additional long-distance conveyor tracks. It directly connects to the output end of the front-end filling and sealing machine, simplifying the structure of the entire line’s conveyor system and reducing the purchase and installation costs of conveyor equipment. It helps enterprises reduce the investment in the entire line of equipment by approximately 15%-20%, making it particularly suitable for small and medium-sized shampoo production workshops.

Linear Coordinate Structure, Efficient, Low-Consumption & More Stable:

The Case Packer Electric Packaging Machines for Shampoo Packing Production Line adopts an advanced linear coordinate structure, driven by precision guide rails and servo motors. Its movements are light and stable, with a packing positioning error ≤ 0.5mm, avoiding collision deformation of shampoo packaging bottles or label wear. Compared with the traditional multi-joint robotic arm structure, the linear coordinate structure has higher transmission efficiency and 25% lower energy consumption (the equipment power is only 4.5Kw, and the power consumption during standby is ≤ 1Kw). Calculated based on 8 hours of operation per day, it can save approximately 8,000 yuan in electricity costs annually. Moreover, it has fewer structural parts and simple maintenance points, with a mean time between failures (MTBF) of more than 7,000 hours, reducing the impact of equipment downtime and maintenance on the production line.

Application Scenarios

Exclusive Scenario for Shampoo Production Lines:

It is adapted to various shampoo packaging forms, such as 500ml PE bottled shampoo (single bottle or combined packaging) and 200ml hose-packed shampoo (multi-piece collective case packing). According to the brand’s packaging needs, it can quickly adjust the packing arrangement (e.g., 3 bottles × 2 rows, 4 bottles × 3 rows). Cooperating with the front-end filling and labeling processes, it realizes the full-process automation of shampoo from production to case packing, improving packaging efficiency and standardization. It is suitable for large, medium, and small shampoo production enterprises.

Supporting Scenario for Daily Chemical Care Products:

In addition to shampoo, it can also be used for case packing of daily chemical care products such as body wash, hair conditioner, and body lotion. For example, it can fill shampoo and body wash of the same brand into gift box cartons in a "1+1" combination, or perform batch case packing of single-category hair conditioners. It meets the needs of daily chemical enterprises for multi-category co-line production, eliminating the need to configure separate case packing equipment for different products and reducing equipment investment.

Auxiliary Scenario for Food and Beverages:

It can be expanded to be used for case packing of bottled water, fruit juice drinks, canned foods, etc. For instance, it can neatly pack 550ml bottled water in a specification of 24 bottles/carton, or perform layered case packing of 330ml canned foods in a specification of 12 cans/carton. It adapts to the large-scale production rhythm of the food and beverage industry, helping enterprises transform from manual case packing to automatic case packing and improving production efficiency.

Frequently Asked Questions

Q1: Can the Case Packer Electric Packaging Machines for Shampoo Packing Production Line adapt to shampoo PE bottles of different heights?

A1: Yes. The height of the equipment’s gripping mechanism supports stepless adjustment of 80-300mm. You only need to enter the height parameters of the shampoo PE bottle on the touch screen, and the system will automatically adjust the gripping stroke and packing depth without replacing mechanical parts. The adaptation process takes only 5 minutes, which can meet the case packing needs of shampoo packaging bottles of different specifications from 50ml to 1L.

Q2: Does the equipment installation require modification of the existing shampoo production line?

A2: No large-scale modification is needed. The equipment’s side-in bottle design can be directly connected to the output end of the existing shampoo filling and sealing machine. Only 2.5m × 3m of equipment installation space and conventional three-phase 380V power supply and 0.6-0.8mpa compressed air interface need to be reserved. The on-site installation and commissioning cycle by engineers is only 2-3 days, which will not cause long-term impact on the normal production of the existing production line.

Q3: If the Case Packer Electric Packaging Machines for Shampoo Packing Production Line breaks down, how fast is the after-sales response?

A3: We provide 7×24-hour after-sales support. After receiving the fault feedback, a professional engineer will provide remote guidance for troubleshooting via phone/video within 15 minutes. If on-site maintenance is required, 6 after-sales service outlets across the country can provide on-site service within 24 hours in provincial capital cities and 48 hours in prefecture-level cities. At the same time, common spare parts (such as sensors and servo motors) are available to ensure the rapid resumption of production and reduce downtime losses.

If you have further questions about the quotation, customization needs (such as special packing specifications), or on-site test run arrangement of the Case Packer Electric Packaging Machines for Shampoo Packing Production Line, please leave your company name, contact information, and product details. Our professional sales team will contact you within 24 hours and provide you with a customized automatic case packing solution to help improve the efficiency of your shampoo production line!