Production managers in beverage factories know glass bottle breakage isn't just a minor annoyance—it's a direct hit to safety records, production schedules, and bottom line costs. When bottles shatter during washing, cleanup crews spend hours picking glass fragments from conveyors and spray systems. Lines stop completely until every shard is cleared to protect downstream filling equipment. Workers face injury risks from sharp edges, triggering stricter safety protocols and potential compensation claims. For high-volume beer and soft drink plants running thousands of bottles per hour, even a 1% breakage rate translates to significant lost production and cleanup expenses.

Tianjin ENAK glass bottle washing machines tackle this problem through engineering choices that prioritize bottle stability from entry to exit. Rather than relying on basic speed reductions or padded surfaces alone, ENAK designs focus on controlled motion paths, precise gripping mechanisms, and conveyor layouts that eliminate high-stress collision points. These approaches help manufacturers achieve near-zero breakage while maintaining line speeds needed for competitive production volumes.

The True Cost of Bottle Breakage Nobody Talks About

Glass bottles fail most often during washing because of sudden acceleration changes, lateral impacts between adjacent bottles, or improper gripping that causes bottles to slip and collide. In returnable bottle systems popular with breweries, worn or chipped bottles from multiple reuse cycles add another layer of risk. A single breakage event can halt an entire line for 30 minutes to two hours, depending on fragment spread and cleanup procedures.

Safety incidents compound the problem. Glass shards create slip hazards on wet floors and pose laceration risks to operators clearing conveyors. Production teams must then follow enhanced lockout procedures, document the incident, and sometimes pause operations for safety audits. For factories processing 20,000+ bottles per hour, resuming full speed after such events takes coordination across multiple shifts.

Financial impact extends beyond immediate downtime. Broken glass contaminates wash water, requiring tank draining and system flushing before restart. Replacement bottles must be sourced quickly, often at premium rates during peak season. Insurance claims for worker injuries add long-term costs. Tianjin ENAK recognizes these cascading effects and builds glass bottle washing machines that systematically reduce breakage probability through mechanical design rather than operator skill alone.

Engineering Gentle Bottle Handling Without Sacrificing Speed

Effective damage prevention starts with understanding how glass bottles fail mechanically during washing. Thin-walled modern bottles—often just 150-180 grams—tolerate vertical compression well but fracture easily under side impacts or twisting forces. ENAK glass bottle washing machines use three complementary engineering strategies to protect bottles throughout the cleaning cycle.

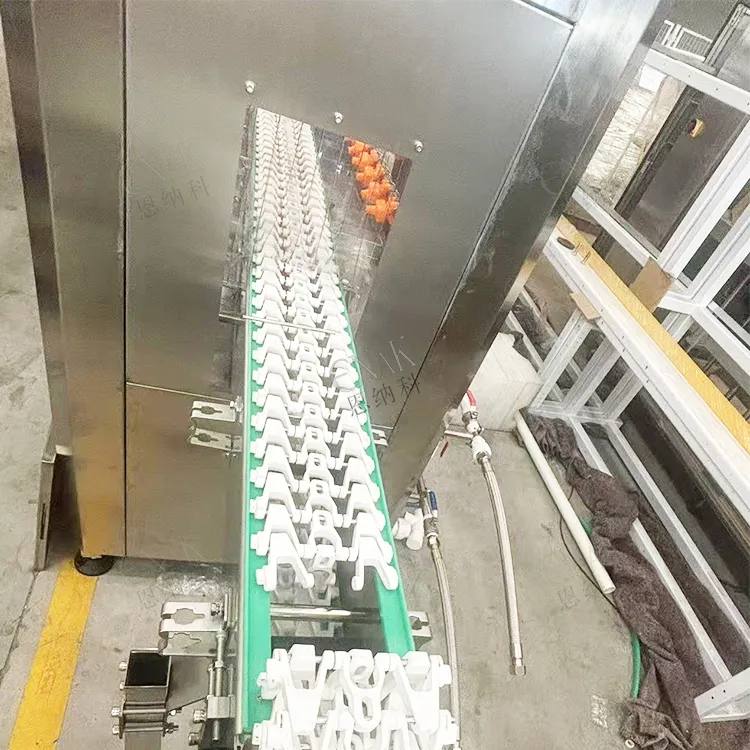

First, gripper systems replace chain-driven pushing common in older washers. Individual bottle holders secure each container by neck finish or base, eliminating jostling between adjacent bottles. Unlike chain pockets that allow bottles to swing or contact neighbors during turns, gripper mechanisms maintain constant bottle-to-bottle spacing. This approach proves particularly valuable when handling returnable beer bottles with irregular wear patterns from multiple filling cycles.

Second, conveyor path geometry eliminates sharp radius turns where bottles traditionally collide. ENAK designs use compound curve transitions and extended straight sections through critical transfer points. Bottles entering spray zones or moving between wash tanks follow smooth parabolic paths rather than abrupt 90-degree shifts. Servo-driven indexing replaces constant-speed chains, allowing precise speed matching during transfers to prevent bunching or gaps.

Third, dynamic damping absorbs vibration before it reaches bottles. Wash zones generate turbulence from high-pressure sprays and air blowers, which traditional rigid conveyors transmit directly to glass. ENAK incorporates elastomeric mounting points and tuned mass dampers that isolate bottle holders from frame vibration. This reduces micro-stresses that accumulate over washing cycles, particularly important for lightweight bottles carrying beer or carbonated beverages under pressure.

Returnable Beer Bottle Washing Demands Specialized Cleaning Power

Returnable glass bottles present unique cleaning challenges beyond breakage prevention. Multiple filling cycles leave stubborn residues that standard washing fails to remove completely. Dried yeast from beer fermentation resists water-only cleaning. Hops oils create slippery films that harbor bacteria. Sugar residues from soft drink batches crystallize in bottle threads and shoulders. Paper or plastic label adhesives leave gummy patches even after soaking.

Tianjin ENAK glass bottle washing machines deploy targeted chemistry and mechanical action for these contaminants. Alkaline pre-soak tanks soften organic buildup before high-pressure jetting. Rotary impingement in dedicated cleaning zones scrubs interior surfaces far more effectively than static spray alone. Bottles rotate 360 degrees under precisely angled nozzles, ensuring shoulders, threads, and bases receive direct impact.

Fresh water final rinses use conductivity monitoring to verify residue removal before bottles proceed to inspection. Automated reject systems divert any bottles failing cleanliness thresholds back to soak tanks, eliminating contaminated containers from reaching fillers. For breweries managing mixed bottle populations from different collection points, configurable wash recipes allow operators to select programs optimized for beer bottles versus juice or soft drink returnables.

Post-wash drying prevents water spotting that leads to label adhesion failures downstream. High-velocity air knives followed by filtered laminar flow remove every drop from interior surfaces. This combination ensures bottles emerge inspection-ready, with no streaks or puddles that trigger manual rejections or filler backups.

Tianjin ENAK Solutions Excel in High-Volume Beer Bottle Operations

Beer factories represent the ultimate test for glass bottle washing machines. Lines run continuously through peak brewing seasons, processing 30,000-60,000 bottles per hour. Returnable bottles arrive in varied condition after consumer handling and transport. Seasonal beers require rapid changeovers between bottle types and wash recipes. ENAK equipment handles these demands through scalable architecture that grows with brewery expansion.

Consider a typical brown glass beer bottle line. Incoming empties pass pre-inspection to remove obviously damaged containers. Surviving bottles enter ENAK washers via gentle accumulation tables that prevent backpressure buildup. Gripper chains elevate bottles into wash zones while inverted orientation allows gravity drainage of loosened debris. Multi-stage chemistry attacks fermentation residues systematically—alkaline jets first, acid neutralization second, sterile rinses last.

Throughput never suffers during recipe changes. PLC controls store bottle-specific wash parameters accessible through touchscreen menus. Operators select "330ml Export Lager" or "500ml Domestic Pilsner" recipes that automatically adjust soak times, jet pressures, and temperatures. Changeover completes in under 10 minutes versus hours required by manual adjustment systems.

Breakage data from similar installations shows ENAK glass bottle washing machines averaging 0.3-0.5% loss rates versus industry standard 1.5-2.0%. Breweries gain 12-18 months payback through reduced bottle purchases, shorter cleanups, and consistent filler performance. Production managers appreciate equipment that runs reliably through 24/7 campaigns without requiring constant babysitting.

Brewery Managers Plan for Five Years of Reliable Operation

Installing a glass bottle washing machine represents a major capital commitment, so breweries evaluate total ownership cost spanning installation through five-year operation. Tianjin ENAK structures equipment for long-term value through accessible maintenance design and predictable parts consumption.

Modular wash tanks bolt together rather than weld permanently, allowing tank replacement without line demolition. Door interlocks permit access to nozzle manifolds without full disassembly. Critical wear components—gripper pads, pump impellers, nozzle inserts—follow standardized sizing across ENAK models, simplifying inventory management.

Preventive maintenance follows clear schedules tied to operating hours. Daily checks verify gripper tension and spray patterns. Weekly inspections examine conveyor bearings and tank levels. Quarterly service replaces predictable wear items before failure disrupts production. ENAK field engineers train brewery maintenance crews during commissioning, transferring skills for independent operation.

Remote monitoring diagnostics reduce unnecessary service calls. Wash controllers log operating parameters and fault history, accessible through secure portals. Production supervisors review trends showing gradual nozzle wear or chemistry imbalances before they impact cleaning quality. This predictive approach prevents 80% of potential line stoppages.

Chinese manufacturing precision underpins long-term reliability. CNC-machined components hold tolerances ensuring consistent wash performance year after year. Food-grade stainless construction resists corrosion from aggressive cleaning chemistries. Robotic welding eliminates inconsistent seams that leak or harbor bacteria over time.

Tianjin ENAK glass bottle washing machines ultimately deliver what brewery managers value most: predictable performance that supports production targets without drama. Lines run cleaner, bottles survive washing intact, maintenance stays routine rather than emergency response. Factories gain confidence knowing equipment matches the reliability of their brewing process while protecting the substantial investment in returnable packaging systems.

Table of Contents

- The True Cost of Bottle Breakage Nobody Talks About

- Engineering Gentle Bottle Handling Without Sacrificing Speed

- Returnable Beer Bottle Washing Demands Specialized Cleaning Power

- Tianjin ENAK Solutions Excel in High-Volume Beer Bottle Operations

- Brewery Managers Plan for Five Years of Reliable Operation