Description

Product Overview

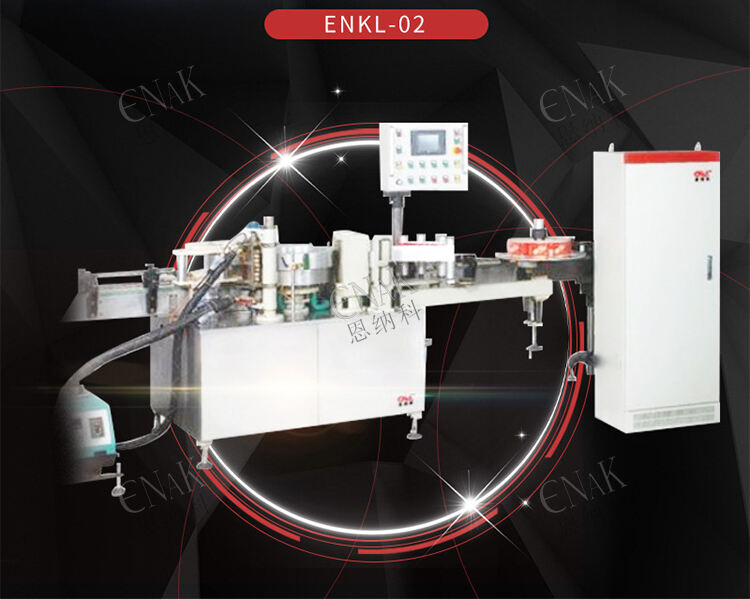

The Industrial Hot Melt Labeler ENKL - 02 is a state - of - the - art labeling solution designed by Tianjin ENAK. Specifically crafted for labeling bottles, cans, jars, and cups, it caters to a wide range of industries such as food and beverage, pharmaceuticals, and cosmetics.

Product Performance

It offers high - speed and accurate labeling. With advanced technology, it can handle a large volume of items in a short time, ensuring efficient production. The hot melt adhesive application provides a strong and long - lasting bond for labels.

Use Scenarios

Whether in a large - scale manufacturing plant with high - volume production or a medium - sized enterprise looking to upgrade its labeling process, this labeler fits well. It can be used for labeling products during the packaging stage, improving the overall aesthetic and brand presentation of the goods.

Parameter |

Details |

Model |

ENKL - 02 |

Labeling Speed |

100 - 300 items per minute |

Power |

1KW |

Dimensions |

265012001100MM |

Package Dimensions |

1203X235X265CM |

Gross Weight |

1500KG |

Precision |

±1 MM |

Applicable Label Type |

Hot Melt Adhesive Labels |

Applicable Product Sizes |

Varies for bottles, cans, jars and cups |

Product Advantages

Automatic Synchronization of Conveyor and Labeling Speeds

The ENKL - 02 is equipped with intelligent sensors that constantly monitor the conveyor speed. It automatically adjusts the labeling speed to match, ensuring seamless operation. This feature eliminates the risk of label misplacement due to speed discrepancies. For example, in a high - speed beverage production line where bottles are moving rapidly, the labeler can keep up, applying labels precisely at the right moment. This not only improves the quality of the labeled products but also reduces waste caused by incorrect label placement.

Integration with ERP or MES Systems for Smart Production Management

By connecting with ERP (Enterprise Resource Planning) or MES (Manufacturing Execution System), the labeler becomes an integral part of the smart factory ecosystem. It can receive production orders directly from the system, adjust labeling parameters accordingly, and report real - time production data back. Manufacturers can track the number of labeled items, monitor the efficiency of the labeling process, and plan their production schedules more effectively. This integration streamlines the entire production process, reducing manual intervention and potential errors.

Automatic Deviation Correction for Precise Label Alignment

The built - in automatic deviation correction function uses advanced image recognition technology. It continuously scans the position of the labels and the products. If any misalignment is detected, it makes immediate adjustments to ensure that the labels are applied accurately. This is crucial for maintaining a professional and consistent appearance of the labeled products. In the cosmetic industry, where brand image is of utmost importance, precise label alignment can enhance the perceived quality of the products.

Production Process

Component Manufacturing

High - quality materials are carefully selected for each component. Precision machining techniques are used to manufacture parts such as the conveyor system, label applicator, and adhesive dispenser. These components are made to strict tolerances to ensure smooth operation.

Assembly

Skilled technicians assemble the components in a clean and controlled environment. They follow detailed assembly procedures to ensure that all parts fit together perfectly. Electrical wiring and control systems are also installed during this stage.

Testing and Quality Assurance

Before leaving the factory, each labeler undergoes rigorous testing. It is tested for labeling accuracy, speed, and the quality of the adhesive bond. Any issues are promptly addressed, and only after passing all the tests is the product ready for shipment.

FAQ

Q: What types of hot melt adhesives can be used with this labeler?

A: It is compatible with a wide range of industrial - grade hot melt adhesives. However, we recommend using adhesives that meet the relevant industry standards for best results.

Q: Can the labeler be customized to label special - shaped products?

A: Yes, to a certain extent. Our engineering team can work with you to assess the feasibility and make necessary modifications to the labeler for special - shaped products.

Q: What is the warranty period for the ENKL - 02?

A: The ENKL - 02 comes with a 3 - year warranty. During this period, we will provide free maintenance and replacement of defective parts (subject to the terms and conditions of the warranty).

If you are interested in our Industrial Hot Melt Labeler ENKL - 02 for Bottles, Cans, Jars and Cups, please feel free to leave your inquiry information below. Our professional sales team will get back to you promptly to discuss your specific needs and provide you with the best solution.