Description

Product Overview:

The Fully Automatic Wine Tape Box Case Former Carton Erector Machine launched by ENAK (Tianjin) Automation Equipment Co., Ltd. is a multifunctional packaging equipment that combines the functions of carton erection and label application for tinplate cans, providing a one-stop solution for the packaging of products like wine.

Product Performance:

It has a powerful box-opening capacity of 50 boxes per minute, which can efficiently meet the production demands. The temporary storage capacity of cartons is 80pcs (800mm), ensuring continuous operation. It is suitable for cartons with dimensions ranging from L: 260 - 450mm, W: 170 - 350mm, H: 110 - 350mm, and the tape size supports 48mm and 60mm. The equipment operates with 380V 3ф and 746W of electricity, with reasonable energy consumption. The required air pressure is 6kg/cm² and the air consumption is 450NL/min. The mechanical dimensions are L3120×W1250×H1740mm, weighing 1200kg. Meanwhile, as a labeler for tinplate cans, it is suitable for labeling products of tinplate cans within the range of 5113 - 15173. It can also quickly change the specifications of different cans with simple operation and the labeling effect is neat and beautiful.

Product Advantages

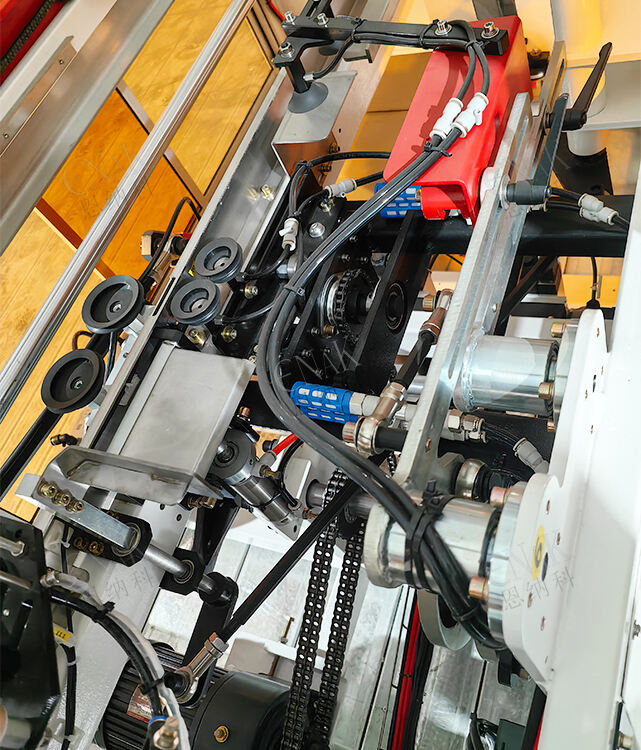

Durable Transmission Structure with Long Service Life:

High-quality transmission parts are adopted, which have undergone special treatment processes and are made of wear-resistant materials, endowing them with excellent durability. The transmission components fit closely and run smoothly, effectively reducing the wear and tear and minimizing equipment failures caused by component damage. This significantly extends the overall service life of the equipment, providing a solid guarantee for the long-term and stable production and operation of enterprises. It also saves the costs and time associated with frequent equipment replacement or maintenance.

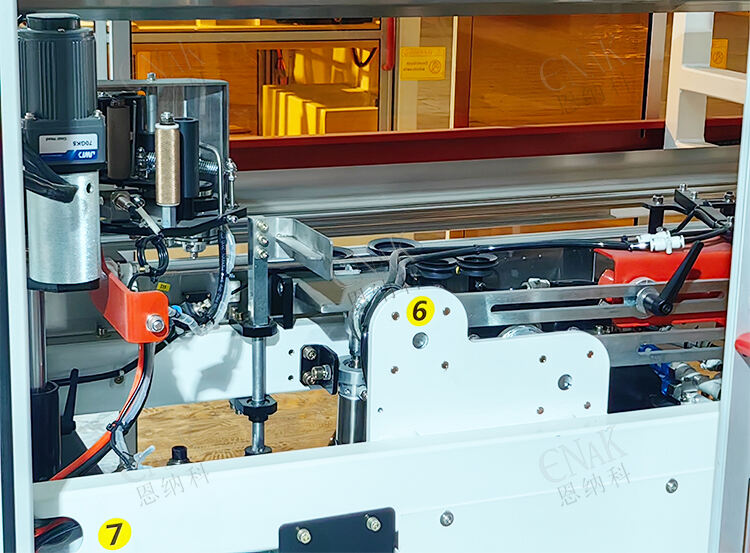

High-Strength Frame with Good Anti-seismic Performance:

The frame of the equipment is fabricated from high-strength steel, and its structural design is scientific and reasonable, having undergone rigorous mechanical tests and optimizations. This robust structure enables the equipment to maintain good stability during operation, regardless of the common slight vibrations in the production workshop or those generated by its own high-speed operation. It ensures the accuracy of carton erection and label application is not affected, guaranteeing the quality of each carton formation and the neatness and beauty of each tinplate can labeling, thus improving the overall quality and consistency of product packaging.

Safety Protection Design in Compliance with CE Standards:

With full consideration for the safety of operators, the safety protection design strictly adheres to the CE standards. The equipment is equipped with multiple safety protection devices. For example, guardrails are installed at key positions to prevent accidental contact with moving parts by personnel. Clear and conspicuous emergency stop buttons are installed, enabling the equipment to be quickly stopped in case of emergencies. It also has an overload protection function to avoid damage to the equipment caused by abnormal conditions such as excessive current, comprehensively safeguarding the personal safety of operators and the normal operation of the equipment, making it more reassuring for enterprises to use.

Product 【Production Process】

Selection of High-Quality Materials:

In the initial stage of production, various high-quality raw materials are carefully selected. For the core mechanical structural components, high-strength, wear-resistant and tough steel with good toughness is chosen to ensure that they can withstand long-term working pressure and frequent mechanical actions. For electrical components, products that meet international standards, are reliable in quality and stable in performance are selected, laying a solid foundation for the stable operation of the equipment.

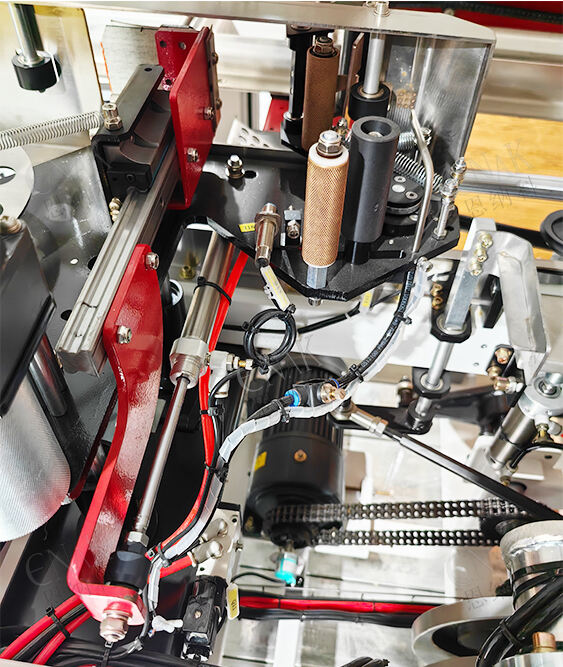

Precision Machining and Manufacturing:

Advanced CNC machining equipment and precise molds are utilized to conduct fine processing on the raw materials. From the cutting, drilling to grinding of components, every process strictly controls the dimensional accuracy and surface quality to ensure high-precision fitting among various components. This enables the equipment to run smoothly and stably after assembly and fully exert its functions to meet the expected performance indicators.

Rigorous Assembly and Debugging:

A professional and experienced technical team assembles the equipment according to a rigorous assembly process. The tightening force of each screw and the installation position of each component are precisely calibrated to ensure the stability and rationality of the overall structure. After assembly, multiple rounds of comprehensive and detailed debugging work are carried out. The box-opening capacity, carton adaptability, label application accuracy as well as electrical and air parameters of the equipment are repeatedly tested and optimized. Only when all performance indicators fully meet the standards will the equipment be delivered to customers, ensuring that customers receive high-quality and high-performance products.

Frequently Asked Questions

Q1: Is the operation of the equipment complicated? Do I need to arrange professional technicians to operate it specifically?

A1: The operation of the equipment is relatively simple and easy to understand. We will provide detailed operation manuals and training services. Ordinary trained workers can operate it proficiently. There is no need to arrange professional technicians to operate it all the time. However, it is recommended that those familiar with the equipment be responsible for routine simple maintenance.

Q2: Is the maintenance of the equipment convenient? Are the spare parts easy to obtain?

A2: The maintenance of the equipment is relatively convenient. We will provide corresponding maintenance guides, informing you of the key points of daily maintenance and the cycle of regular maintenance. Moreover, we have a complete spare parts supply system, and common spare parts are in sufficient stock, facilitating you to purchase and replace them in time when needed to ensure the normal operation of the equipment.

Q3: Is the equipment easily damaged during transportation? How do you ensure the safety of transportation?

A3: We have rich experience and a professional process in equipment packaging and transportation. The equipment will be properly packaged and protected, using sturdy packaging materials and being reasonably fixed according to its characteristics to ensure that it can withstand normal bumps and vibrations during transportation and minimize the risk of damage. Meanwhile, we will also purchase corresponding transportation insurance to provide multiple safeguards for the safety of the equipment.

If you are interested in our Fully Automatic Wine Tape Box Case Former Carton Erector Machine, please feel free to leave your inquiry information. We will contact you as soon as possible, providing you with more detailed product information and professional product services to help make your packaging production work more efficient and convenient.