Description

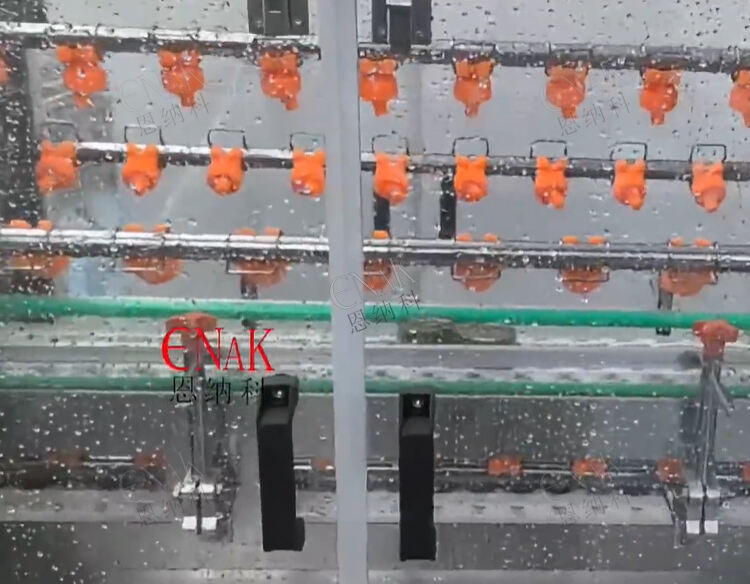

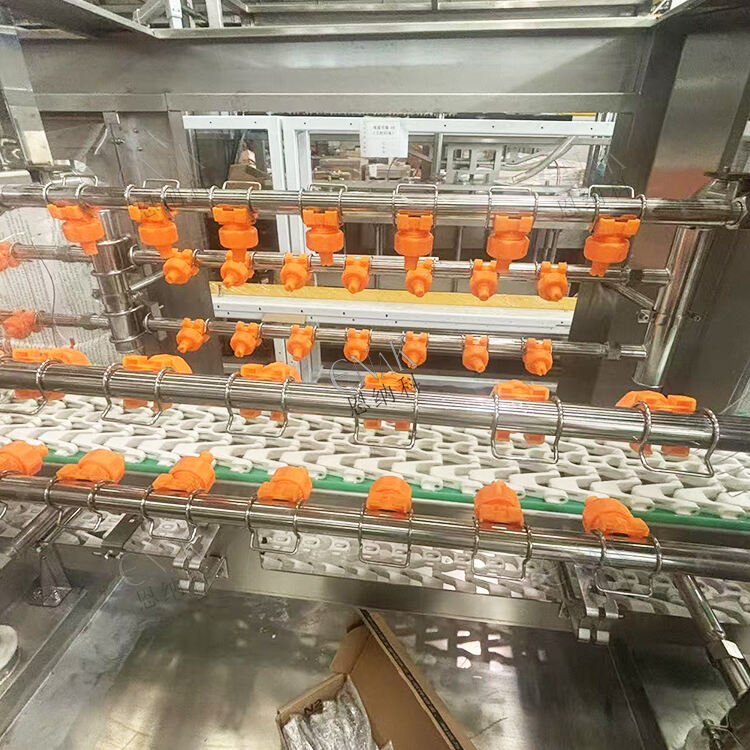

ENAK (Tianjin) Automation Equipment Co., Ltd proudly presents the ENKQ-01 Filled Beverage Cans Washing Machine and Milk Can Washer, an advanced cleaning system designed specifically for filled cans used in the dairy and beverage industries. This machine ensures thorough and hygienic cleaning of both beverage cans and milk cans before further processing or packaging.

- Product Overview: The ENKQ-01 employs multi-stage washing technology that cleans the interior and exterior surfaces of cans, removing residues, contaminants, and microbes effectively.

- High Cleaning Efficiency: Equipped with multiple specialized washing tanks and precision spray nozzles, it delivers rapid and consistent cleaning cycles suitable for large-scale production.

- Robust and Hygienic Construction: Made from food-grade stainless steel, the machine complies with safety and hygiene standards, ensuring no contamination risk during cleaning.

- Automation and Control: The system integrates seamlessly with upstream and downstream equipment, complete with automated controls to synchronize the washing process within your production line.

- Energy and Water Efficient: Designed with water recycling and heat recovery systems to optimize resource use and reduce operational costs.

- User-Friendly Operation: Features intuitive interfaces for easy parameter setup, monitoring, and troubleshooting, saving time and improving production control.

Product Advantages

ENKQ-01 excels in delivering high-performance washing with safety, reliability, and automation:

Food-Grade Safety Materials

The machine is constructed entirely from food-grade stainless steel and other materials that meet or exceed industry hygiene requirements. This ensures that no contaminants or harmful substances leach into the cans during washing, preserving product safety and quality. Smooth surface finishing and sanitary welds prevent bacteria buildup, facilitating easy cleaning and maintenance.

Automated Linked Control

ENKQ-01 supports integrated automated control systems, allowing it to communicate seamlessly with adjacent packaging and filling equipment. The washing process is fully synchronized, reducing manual interventions and ensuring smooth production flow. Programmable logic controllers (PLCs) regulate washing duration, water temperature, and spray pressure to optimize cleaning performance automatically, improving consistency and reducing operator workload.

Reliable and Stable Operation

Built with durable components sourced from internationally recognized brands, the machine guarantees stable performance even under continuous heavy-load conditions. Precision-engineered parts and advanced servo motors minimize vibration and wear, extending machine lifespan and reducing downtime. Automated error detection and protective shutdown mechanisms enhance operational safety and reliability, ensuring uninterrupted production.

Efficient Resource Use

Water reuse through filtration and recirculation reduces consumption drastically without compromising cleaning quality. Heat recovery systems capture thermal energy from wash water for reuse, lowering energy costs and environmental impact. These eco-friendly features contribute to sustainable manufacturing goals.

Flexible Adaptability

The machine’s modular design and adjustable fixtures accommodate different can sizes and shapes, offering high flexibility to adapt to evolving product lines and production scale adjustments.

Ease of Maintenance and Operation

The simple control interface and modular components enable quick maintenance and cleaning, minimizing downtime and increasing overall equipment effectiveness. Operator training is fast due to intuitive software interfaces.

Manufacturing Process

ENAK follows rigorous procedures in building the ENKQ-01 to guarantee reliability and compliance:

Precision Fabrication

Components are manufactured using high-precision CNC machining and laser cutting technologies to maintain tight tolerances and ensure perfect assembly fits, crucial for maintaining wash pressure and flow.

Sanitary Welding and Surface Treatment

Welds are executed according to sanitary standards, with smooth finishes eliminating crevices that could harbor bacteria. Surface polishing enhances corrosion resistance and facilitates quick cleaning.

Material Selection

Only FDA-approved stainless steel grades and food-safe materials are used. All contact parts comply with hygienic design principles to prevent contamination.

Quality Control Testing

Each machine undergoes exhaustive inspections, including leak testing, spray coverage verification, and running-in processes to validate performance integrity before shipment.

System Integration Calibration

The automated control modules are configured and tested in factory conditions to ensure seamless interfacing with customer production lines and optimized process timing.

Environmental Considerations

Assembly includes installation of water and energy-saving subsystems, with monitoring to ensure efficiency standards are met prior to delivery.

FAQ

Q1: What types of cans does ENKQ-01 support?

A: It is designed primarily for filled beverage cans and milk cans in various standard sizes.

Q2: How does the washing process ensure cleaning quality?

A: Multi-stage washing with hot water, alkali solutions, and rinse cycles ensures removal of all residues and microbial contaminants.

Q3: Is the system compatible with other production equipment?

A: Yes, it supports automated linkage with filling and packaging lines through standard communication protocols.

Q4: How energy and water efficient is the machine?

A: It features water filtration recycling and heat recovery systems, significantly reducing resource consumption.

Q5: Is the machine easy to operate and maintain?

A: The user-friendly touchscreen interface and modular design simplify operation and maintenance tasks.

We warmly invite you to contact ENAK (Tianjin) Automation Equipment Co., Ltd to learn more about the ENKQ-01 Filled Beverage Cans Washing Machine and Milk Can Washer. Our experienced team is ready to provide customized solutions tailored to your production needs, improving hygiene, efficiency, and sustainability.

Please click the “Inquiry” button below or get in touch directly to submit your project requirements. We will promptly offer expert consultation, competitive pricing, and comprehensive technical support to help modernize your production line with efficient, reliable washing technology.