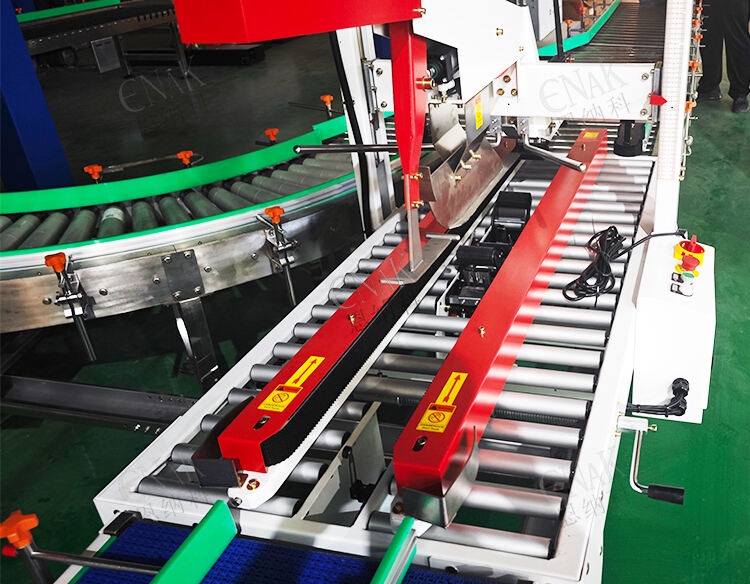

Custom Food Production Line Adhesive Tape Carton Box Seal Packing Sealing Packaging Machine ENKF-02

Description

Overview:

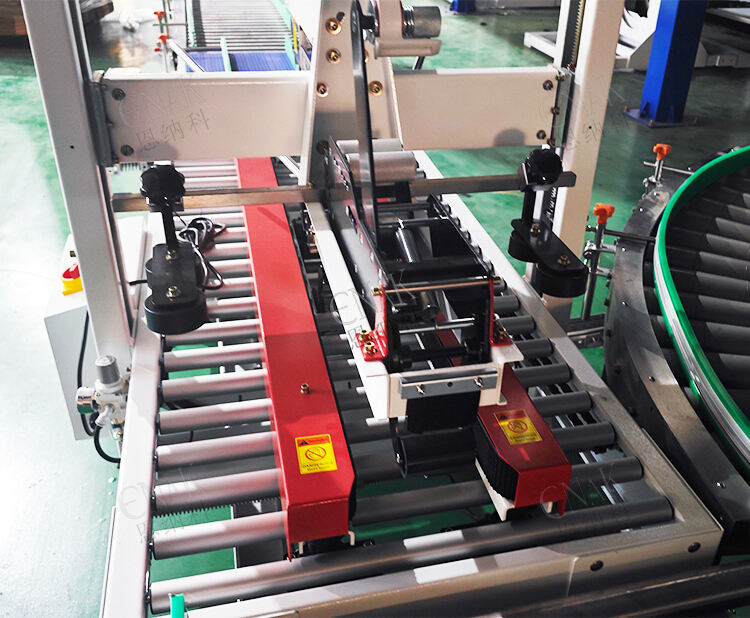

The Carton Box Seal Packing Sealing Packaging Machine (full-automatic folding cover carton sealer) is designed for unmanned assembly lines. It realizes full-process automation of carton conveying, cover folding and sealing without manual intervention, suitable for large-scale packaging needs in food, daily chemical, electronics industries, and effectively improves production line continuity.

Core Performance:

Within the applicable carton specifications (length 200-600mm, width 150-500mm, height 120-500mm), it automatically identifies sizes and adjusts parameters without manual debugging; the sealing speed reaches 25 cartons per minute, meeting medium and high-yield production rhythms; parts are manufactured with high precision, running stably without shaking, and the service life can reach 8-10 years.

Key Parameters:

Compatible with tape widths of 48mm/60mm/75mm, adapting to mainstream carton sealing tapes; power supply optional 220/380V 50Hz, adapting to different workshop power configurations; power 400W, low energy consumption; equipment size L1770×W850×H1520mm, weight 250kg, small footprint, flexible layout.

Product Advantages

Full-Automatic & Unmanned, More Significant Cost Reduction & Efficiency Improvement:

Integrates full-process automation of carton automatic conveying, top cover folding, and upper-lower tape sealing, no need for manual cover folding or carton feeding. It can replace 2-3 sealing workers, saving 150,000-200,000 yuan in annual labor costs based on 10 hours of daily operation and a monthly salary of 5,000 yuan. At the same time, the sealing flatness error is ≤1mm, avoiding problems such as skewed cover folding and tape bubbles caused by manual operation, increasing the product packaging qualification rate to 99.9% and reducing rework losses.

Multi-Specification Self-Adaptation, More Flexible & Convenient Debugging:

Within the specifications of 200-600mm (length), 150-500mm (width), 120-500mm (height), it can complete adaptation and switching of cartons of different sizes in 0.5 seconds without replacing mechanical parts or disassembling and adjusting. For example, switching from a small snack carton to a large daily chemical carton requires no downtime, greatly reducing downtime losses caused by specification switching. It also supports three tape widths (48mm, 60mm, 75mm), which can be adapted by quickly replacing the tape shaft, meeting the packaging appearance needs of different customers.

Durable & Low-Consumption, More Economical & Worry-Free Operation:

Core components are made of high-quality materials - conveyor rollers are high-strength nylon, with a wear resistance coefficient 3 times that of ordinary plastic, and can run continuously for 50,000 hours without obvious wear; tape cutting knives use imported high-speed steel, maintaining sharpness for a long time, and can cut more than 80,000 times continuously without replacement. The equipment has a trouble-free operation time of over 10,000 hours, with low maintenance frequency; power is only 400W, calculated based on 8 hours of daily operation and 1 yuan/kWh electricity fee, the daily electricity fee is 3.2 yuan, and the annual electricity fee is less than 1,200 yuan, saving 40% energy compared with similar equipment, and the long-term use cost is lower.

Application Scenarios

Food & Beverage Industry:

Suitable for sealing bottled water, canned foods, snack gift boxes and other products, and can be seamlessly connected with front-end filling lines and case packing lines, realizing full-process unmanned operation from product production to sealing. It avoids food pollution caused by manual contact, complies with food industry hygiene standards, and meets the large-scale production demand of more than 100,000 cartons per day.

Daily Chemical Industry:

Used for sealing large-specification cartons of daily chemical products such as shampoo, body wash, and laundry detergent. It accurately handles product cartons of different heights, with flat and beautiful folding cover sealing, improving the shelf display effect of products. At the same time, it supports multi-width tapes, which can be selected according to brand packaging design to meet differentiated packaging needs.

Electronics & Home Appliance Industry:

Adapts to sealing cartons of small home appliances (such as rice cookers, electric fans) and electronic accessories (such as mobile phone chargers, earphones). The operation process is stable without vibration, avoiding displacement of internal parts of electronic products; the sealed cartons have strong pressure resistance, which can reduce collision damage during transportation and ensure product delivery quality.

Frequently Asked Questions

Q1: Can the equipment adapt to special-shaped cartons with handles?

A1: It is not supported under normal conditions. Special folding cover guide components need to be customized according to the handle position to adjust the mechanical linkage trajectory. The customization cycle is about 7-10 days. Carton samples can be provided to evaluate feasibility, and the original multi-specification adaptation capability of the equipment will not be affected after customization.

Q2: The tape is easy to fall off after sealing. What is the reason?

A2: This is mostly caused by improper tape tension or insufficient pressure wheel pressure. The tape tightness can be adjusted via the tension knob on the side of the equipment (rotate clockwise to increase tension), or the pressure wheel height can be lowered by turning the pressure wheel adjustment knob to enhance the adhesion between the tape and the carton. The operation is simple and can be solved within 5 minutes.

Q3: The equipment suddenly stops without fault prompt. How to handle it?

A3: First, check whether the power connection is normal (whether 220V/380V is energized) and whether the air source pressure meets the standard (needs to be maintained at 5-6Kg/m²); if both are normal, check whether there is foreign matter blocking the carton conveying channel. After removing the foreign matter, press the "Reset" button to restart the equipment, which can usually resume operation within 10 minutes.

If you have further questions about the quotation, customization needs (such as adaptation to special-shaped cartons), or on-site test run arrangement of the Carton Box Seal Packing Sealing Packaging Machine, please leave your company name, contact information and the specifications of the cartons to be sealed. Our professional sales team will contact you within 24 hours and provide you with a customized carton sealing solution to help improve the automation level of your packaging production line!