Description

The Canned Tuna Labeler Machine is a high-efficiency labeling solution developed by Tianjin ENAK Automation Equipment Co., Ltd. for tinplate cans. This machine is specifically designed to automatically label sealed tin cans, supporting both stand-alone operations and integration with full production lines.

Models:

Two versions are available—ENKG-01 for small cans and ENKGD-01 for larger cans—offering flexibility for different packaging requirements.

Compact Structure:

Designed for simplicity, the machine is easy to operate, quick to adjust, and compatible with multiple can types, significantly reducing labor costs.

Performance:

Built on the principle of high speed, stability, and space efficiency, the Canned Tuna Labeler Machine ensures precise and consistent labeling, boosting enterprise productivity.

Applications:

Primarily used for tinplate can labeling, it is widely adopted in the food, beverage, and chemical industries. It is especially suited for bulk production of canned tuna and similar products

Item |

Specification |

Standard Capacity |

50–400 cans/min (labeling speed depends on can diameter and size) |

Operation Mode |

Button & knob control |

Weight of Labeled Material |

30g – 4200g |

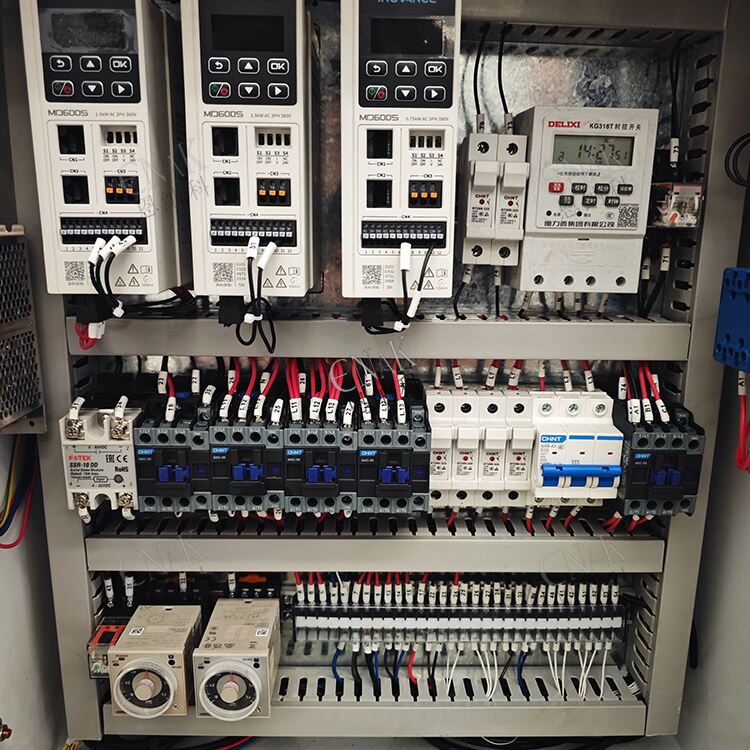

Motor Power Supply / Power |

Three-phase five-wire, AC 380V / 50Hz; Single machine: 3kW; Full line: 6kW |

Control Voltage |

DC 24V |

Air Consumption |

60 NL/min (Air pressure: 2–4 kg/cm²) |

Air Pipe Connection Size |

φ8mm |

Machine Dimensions |

ENKG-01: (L)1940mm × (W)752mm × (H)1263mm |

Working Environment |

Altitude: 3–2000m; Temperature: 0℃–40℃; Humidity: 40%–95% |

Machine Weight |

ENKG-01: 750kg; ENKGD-01: 900kg |

Label Size Requirements |

ENKG-01: Max. L×W = 390×254mm; Min. L×W = 150×20mm |

Adhesive Requirement |

Hot melt adhesive + quick-drying adhesive |

Production Line Height |

Inlet height: 1100–1200mm; Outlet height: 700–800mm |

Can Body Diameter Requirements |

ENKG-01: φ55–φ120mm; ENKGD-01: φ55–φ160mm |

Product Advantages

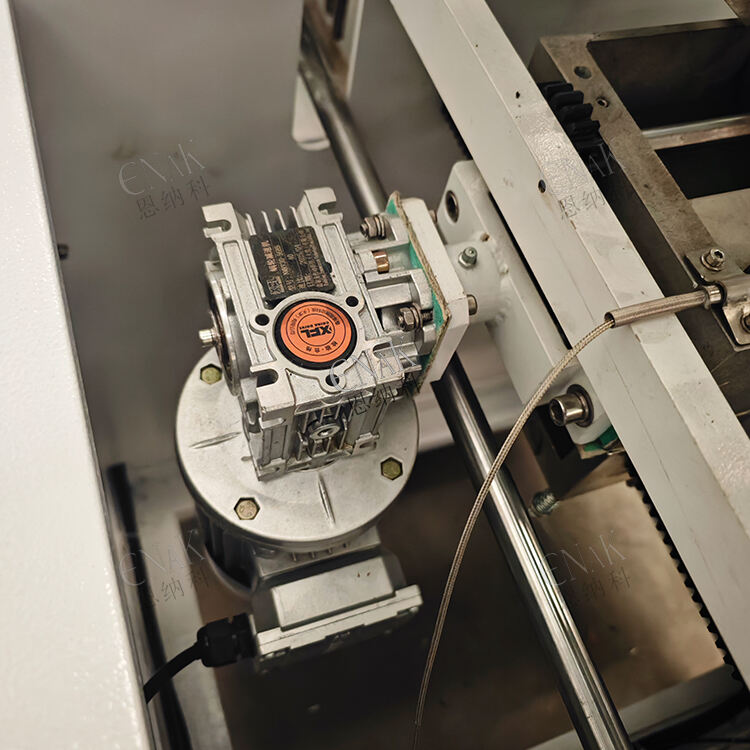

1. Reliable Materials and Compliance

The Canned Tuna Labeler Machine is constructed from stainless steel, aluminum alloy, engineering plastics, and carbon steel with electroplating. This durable build ensures long-term performance while meeting national food and machinery standards for safety and reliability.

2. Space-Saving and Cost-Effective

With a compact footprint, the machine reduces the need for complex conveyor systems before labeling, thereby lowering total equipment investment costs. For factories with high-volume labeling needs, this design saves both space and capital.

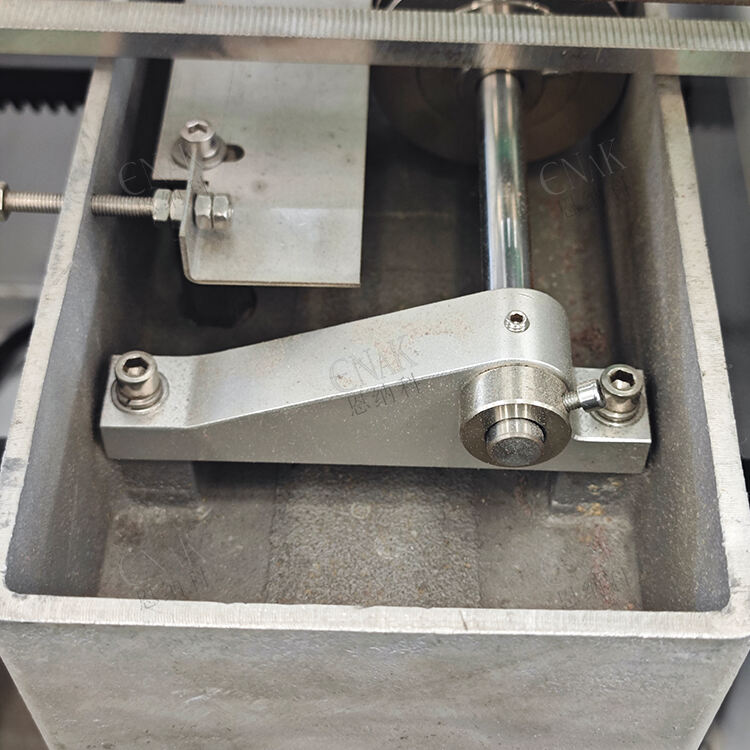

3. Hydraulic Label Feeding with Continuous Operation

The machine uses a hydraulic cylinder for label feeding and is equipped with dual labeling mechanisms. These can alternate without requiring shutdowns, ensuring uninterrupted operation (excluding labels narrower than 35mm). This feature greatly improves productivity.

4. Intelligent Photoelectric Control

The glue supply system is controlled by a photoelectric sensor, ensuring glue is dispensed only when cans are present. This reduces glue waste and prevents idle operation, supporting efficiency and sustainability.

5. Easy Can Changeover

Switching to different can sizes is simple and requires minimal parts replacement. This ease of changeover reduces downtime and boosts production flexibility.

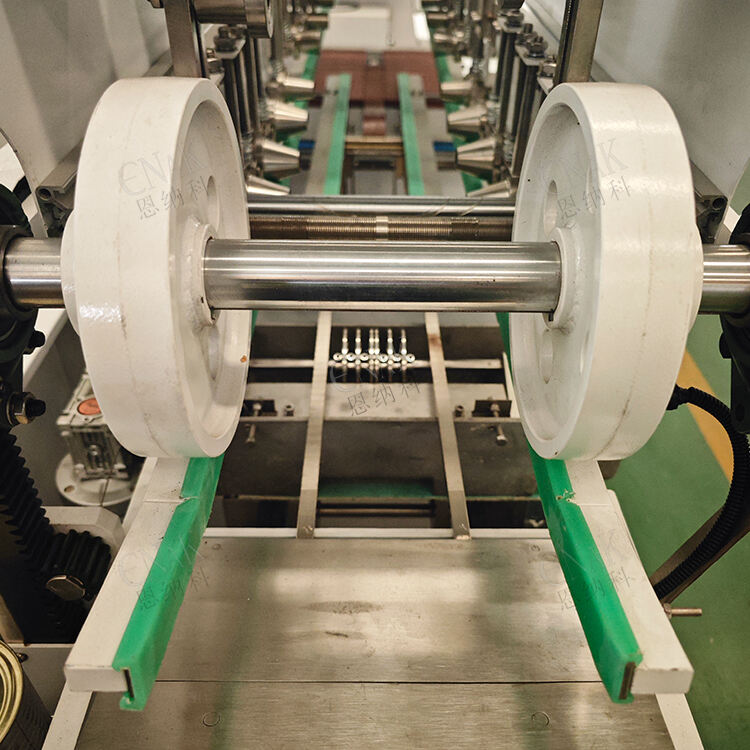

6. Polymer Wear-Resistant Tracks

All machine tracks in contact with cans are fitted with high molecular wear-resistant strips. This design reduces can body abrasion during transport and labeling, preserving appearance and quality.

7. Strong Adhesion with Dual Glue Points

For two-piece cans, an additional glue point has been designed, making label adhesion stronger and more secure, effectively preventing detachment.

8. Economical Glue Usage

Glue is applied only at the two ends of the label, reducing adhesive consumption while maintaining strong bonding. This lowers labeling costs for long-term operations.

9. Branded Electrical Components

Over 95% of the electrical components used in the Canned Tuna Labeler Machine are sourced from world-renowned brands. This ensures high efficiency, stability, and durability even during extended production cycles.

10. Low Noise, International Standards

The machine operates at noise levels below 75db, meeting international standards. This makes the working environment more comfortable for operators.

Product Application Scenarios

The Canned Tuna Labeler Machine is widely applied in food canning, beverage production, chemical packaging, and other industries where tinplate labeling is required. Its efficient and stable performance makes it a top choice for high-volume processing lines

Food Industry:

In canned tuna production lines, the Canned Tuna Labeler Machine efficiently labels finished products, ensuring consistent quality and improving automation levels.

Beverage and Condiment Industry:

For metal-canned drinks and sauces, the Canned Tuna Labeler Machine guarantees accurate labeling and a professional appearance.

Chemical Industry:

Many chemical products require tinplate packaging. The Canned Tuna Labeler Machine adapts to various specifications, ensuring safe and standardized labeling.

Export Packaging:

With global trade, different languages and label formats are often required. The Canned Tuna Labeler Machine provides precise, customizable solutions for international buyers.

In all these scenarios, the Canned Tuna Labeler Machine not only delivers high-quality labeling but also supports smart control, energy efficiency, and reduced adhesive costs. For bulk buyers seeking sustainability, reliability, and long-term value, the Canned Tuna Labeler Machine is the ultimate choice.

FAQ

Q1: Can the Canned Tuna Labeler Machine support different can sizes?

A1: Yes, it can. The machine is easy to adjust and requires only minimal part replacements.

Q2: Does the machine need to stop for reloading labels?

A2: No. The dual labeling system allows continuous operation without stopping.

Q3: Is the machine energy-efficient and eco-friendly?

A3: Absolutely. With photoelectric sensor control and optimized glue usage, it minimizes waste and energy consumption.

Q4: Which industries is the Canned Tuna Labeler Machine suitable for?

A4: Mainly the food, beverage, condiment, and chemical industries, particularly canned tuna production lines.

If you are looking for a high-performance, reliable, and eco-friendly labeling solution, the Canned Tuna Labeler Machine from Tianjin ENAK Automation Equipment Co., Ltd. is the right choice. Our machine combines durability, smart design, and operational efficiency to help businesses streamline production and reduce costs.

Contact us today to leave your inquiry. Our professional team will provide customized solutions, competitive pricing, and bulk order support to upgrade your labeling process.