Description

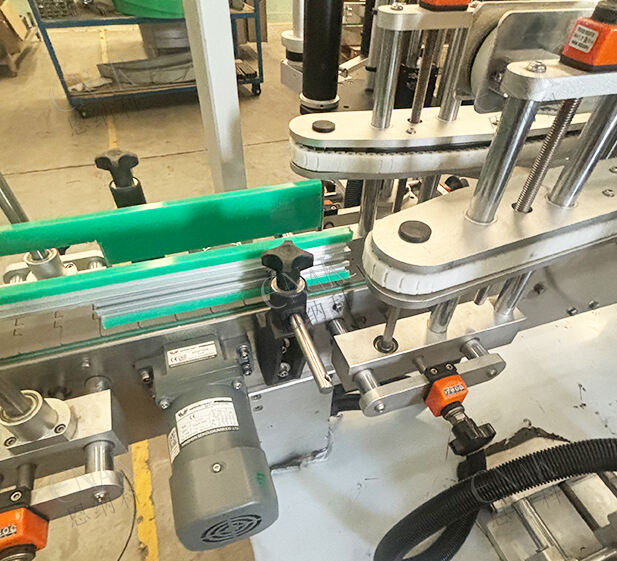

The High-Speed Energy-Saving Single sided labeling machine ENKB-12 from Tianjin ENAK is a cutting-edge labeling system engineered to meet the demands of modern automated production lines. Designed for high efficiency, accuracy, and versatility, this machine integrates premium components including a 750W ultra-low inertia Yaskawa servo motor, Siemens PLC controller, and advanced German Leuze sensors. The ENKB-12 excels in single-sided, double-sided, and wrap-around labeling, making it adaptable to a wide range of bottling and packaging applications.

Key features include:

High Labeling Accuracy: The ENKB-12 achieves ±1mm precision using servo motor closed-loop control and dual pressure roller labeling technology, ensuring flawless application even on transparent or tapered containers.

Multi-Container Compatibility: Capable of labeling round, square, flat, and taper-shaped bottles, the machine features an eight-dimensional adjustable labeling head for effortless angle adjustments without tools. It supports various label materials including transparent films, PVC, and paper.

Energy-Saving and High-Speed: The 750W Yaskawa motor allows precise speed adjustments from 0.5 to 50 meters per minute, enabling it to synchronize with different production lines to optimize throughput while reducing power consumption.

Robust and Hygienic Construction: Constructed from food-grade 304 stainless steel and anodized aluminum alloy, the machine delivers durability and meets stringent sanitary requirements.

User-Friendly Operation: A bilingual (Chinese-English) color touchscreen interface allows operators to easily manage settings with the ability to store 10 product profiles for swift production changeovers.

This labeling machine is ideal for industries such as pharmaceuticals, food and beverage, cosmetics, and chemicals, where speed, precision, and flexible labeling capability are critical for production efficiency.

| Parameter | Specification |

| Operation Mode | Human-Machine Interface (Chinese-English) |

| Labeling Speed | 50 meters per minute maximum |

| Labeling Accuracy | ±1mm |

| Motor Power | 2.25 kW (Single-phase AC 220V, 50Hz) |

| Control Voltage | DC 24V |

| Maximum Label Roll Diameter | 330mm |

| Maximum Label Width/Height | 190mm |

| Core Diameter | 76.2mm |

| Machine Dimensions (L×W×H) | 3040mm × 1366mm × 1830mm |

| Operating Environment | Altitude: 3–2000m; Temperature: 0–40°C; Humidity: 40–95% |

| Machine Weight | 500 kg |

| Conveyor Chain Height | 900 ± 50 mm |

| Conveyor Chain Width | 82.6 mm |

Product Advantages

Versatile Labeling: Supports Single-Sided, Double-Sided, and Wrap-Around Labeling

The High-Speed Energy-Saving Single sided labeling machine ENKB-12 can be easily configured for different labeling styles. Its labeling head and mechanical systems allow seamless switching between single-side, double-side, and wrap-around labeling modes. This flexibility enables manufacturers to reduce capital expenses and production floor complexity by consolidating multiple labeling needs into one machine.

Seamless Integration with Automated Production Lines

Designed to work in harmony with fillers, cappers, and cartoning equipment, the ENKB-12 supports continuous line operations with stable throughput. The imported 750W AC motor combined with a large capacity Danfoss frequency converter stabilizes conveyor speeds. Adjustable photoelectric sensors allow zero-delay triggering for instant and precise label application. These features minimize production downtime and ensure consistent product quality.

Adaptability to Various Label Materials and Container Types

The ENKB-12 labels a wide range of materials such as transparent film, PVC, and paper labels with minimal waste. Its dual pressure roller system and sponge spring-steel combination ensure wrinkle-free, bubble-free application. Furthermore, the eight-dimensional adjustable labeling head allows operators to precisely position labels on irregular, tapered, or transparent bottles. This ensures high product appearance standards and regulatory compliance.

Production Process

Precision Mechanical Assembly

The High-Speed Energy-Saving Single sided labeling machine ENKB-12 is constructed from food-grade 304 stainless steel and anodized aluminum alloy with professional surface treatments such as electrophoresis and oxidation. This delivers superior corrosion resistance, hygienic standards, and ease of cleaning.

Integration of Advanced Automation Components

This machine incorporates a 750W ultra-low inertia Yaskawa servo motor for precise motion control, complemented by a Siemens programmable logic controller (PLC) for intelligent closed-loop feedback. German Leuze sensors provide high-accuracy label detection to ensure consistent application.

Modular and Ergonomic Design

The machine’s conveyor, bottle guide rails, labeling head, and pressing units are modular and designed for quick adjustment or replacement. The eight-dimensional adjustable labeling head is designed so operators can fine-tune angles without tools, reducing downtime during product changeovers.

Comprehensive Quality Assurance

Each unit undergoes strict inspection for labeling accuracy, speed consistency, mechanical stability, and safety compliance before shipping to guarantee the performance of the High-Speed Energy-Saving Single sided labeling machine ENKB-12 in demanding industrial environments.

FAQ

Q1: What types of containers are compatible with the High-Speed Energy-Saving Single sided labeling machine ENKB-12?

A1: It supports round, square, flat, and tapered containers, giving manufacturers flexibility across diverse product lines.

Q2: Can the ENKB-12 be connected with existing filling or packaging equipment?

A2: Yes, it is designed for smooth integration with filling machines, cartoners, and other packaging lines to enable automated production workflows.

Q3: What label materials does the machine support?

A3: Transparent labels, paper labels, PVC, and other common labeling materials are fully compatible.

Q4: How precise is the labeling output?

A4: The machine delivers highly accurate labeling with an error margin within ±1mm.

Q5: Can it store multiple product configurations?

A5: Yes, it can store up to 10 product parameters to allow fast switching and improve production efficiency.

For further details or customized solutions, please contact Tianjin ENAK. Experience how the High-Speed Energy-Saving Single sided labeling machine ENKB-12 can modernize your production line with enhanced speed, precision, and flexibility.