Description

Product Overview

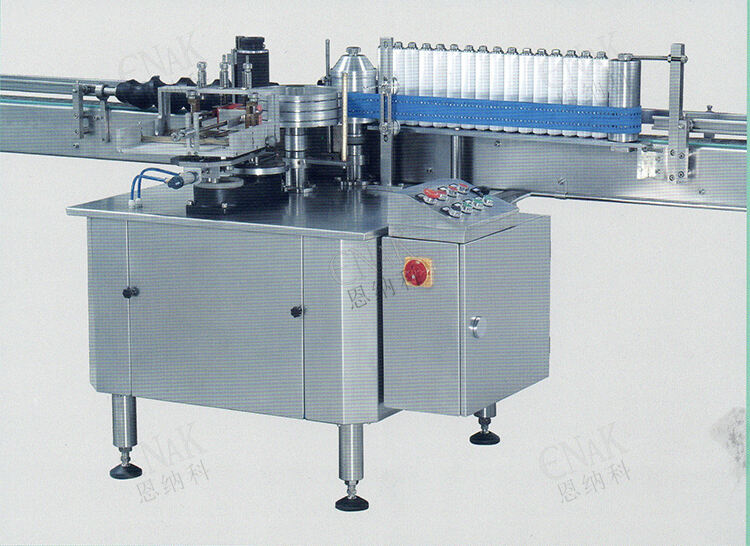

The Single - side paste labeling machine ENKL - 03 by Tianjin ENAK is a specialized labeling solution crafted specifically for the food and beverage industry. It is designed to apply labels accurately and efficiently on various food and beverage products, enhancing brand presentation and product identification.

Product Performance

This labeling machine offers high - precision labeling with an accuracy of ±1 MM. It can handle a labeling speed of 40 - 120 items per minute, ensuring a smooth and continuous labeling process for medium - to high - volume production scenarios. The paste application system provides a strong and long - lasting label adhesion.

Use Scenarios

In the food and beverage industry, whether it's labeling bottles of soft drinks, cans of beer, or jars of preserves, the ENKL - 03 fits right in. It can be used in large - scale manufacturing plants as well as small - to medium - sized enterprises looking to upgrade their labeling operations. It helps in meeting the strict regulatory requirements for product information display on labels.

Parameter |

Details |

Model |

ENKL - 03 |

Labeling Speed |

40 - 120 items per minute |

Power |

1KW |

Dimensions |

28008501100MM |

Package Dimensions |

200X80X135CM |

Gross Weight |

600KG |

Precision |

±1 MM |

Applicable Label Type |

Paste - based Labels |

Applicable Product Types |

Food and Beverage Products (e.g., bottles, cans, jars) |

Product Advantages

Low Energy Consumption with Energy - saving Drive System

The ENKL - 03 is equipped with an advanced energy - saving drive system. This system is designed to optimize power usage during the labeling process. By reducing unnecessary power consumption, it not only helps in cutting down operational costs for food and beverage manufacturers but also aligns with the growing trend of sustainable production. For example, in a large - scale beverage factory running multiple shifts, the energy savings over time can be substantial, making it an economically and environmentally friendly choice.

Anti - misfeeding Device to Avoid Label Waste

The built - in anti - misfeeding device is a crucial feature of the ENKL - 03. It constantly monitors the label feeding mechanism. If it detects any abnormal feeding, such as double - feeding or misaligned labels, it immediately stops the process. This prevents labels from being wasted, which is especially important considering the cost of labels and the need for efficient production. In a food packaging line where labels are customized and expensive, this feature can save a significant amount of money.

Automatic Shutdown and Fault Alert Function

When a fault occurs in the machine, such as a mechanical jam or an electrical issue, the ENKL - 03 has an automatic shutdown function. This protects the machine from further damage and ensures the safety of the operators. At the same time, it sends out a clear fault alert, which can be in the form of visual signals or audible alarms. Maintenance staff can quickly identify the problem and start the repair process, minimizing production downtime in the food and beverage production line.

Production Process

Material Selection and Procurement

High - quality materials are carefully selected for the construction of the ENKL - 03. Steel for the frame is sourced from reliable suppliers to ensure durability. Electronic components are chosen for their stability and long - term performance. All materials undergo strict quality inspections upon arrival at the factory.

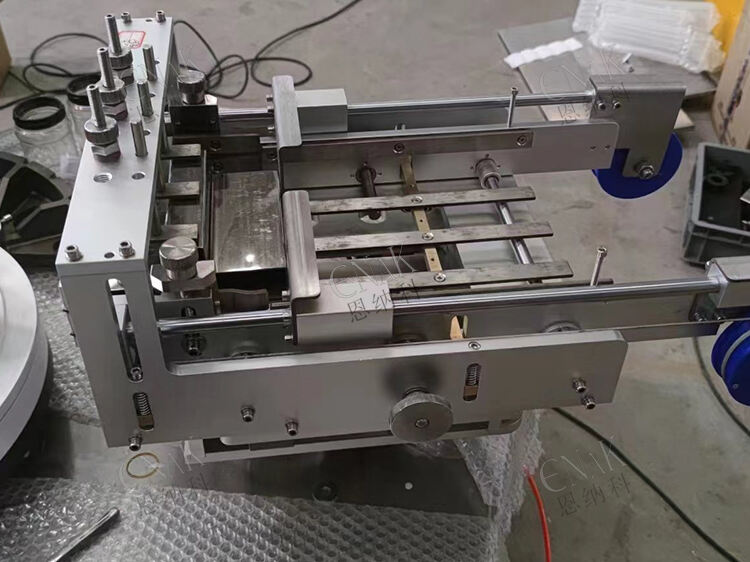

Component Fabrication and Assembly

Skilled technicians use precision machining techniques to fabricate components such as the label applicator and conveyor parts. These components are then assembled with great care in a controlled manufacturing environment. Electrical wiring and control systems are integrated during the assembly process to ensure seamless operation.

Testing and Quality Assurance

Before leaving the factory, the ENKL - 03 goes through comprehensive testing. Labeling accuracy, speed, and the functionality of all features are thoroughly checked. Any potential issues are addressed promptly. Only after passing all the tests is the machine certified for shipment to customers in the food and beverage industry.

FAQ

Q: What types of paste can be used with this labeling machine?

A: The ENKL - 03 is compatible with a variety of food - grade paste adhesives. However, we recommend using adhesives that meet the relevant industry standards to ensure proper label adhesion and food safety.

Q: Can the labeling speed be adjusted according to different production requirements?

A: Yes, the labeling speed of the ENKL - 03 can be adjusted within the range of 40 - 120 items per minute to meet different production needs. Our technical support team can assist you in making the appropriate adjustments.

Q: How long is the warranty period for the ENKL - 03?

A: The ENKL - 03 comes with a 3 - year warranty. During this period, we will provide free maintenance and replacement of defective parts (subject to the terms and conditions of the warranty).

If you are interested in our Single - side paste labeling machine ENKL - 03 for the food and beverage industry, please leave your inquiry information below. Our dedicated sales team will get back to you promptly to discuss your specific requirements and offer you the best solution.