Description

Product Overview

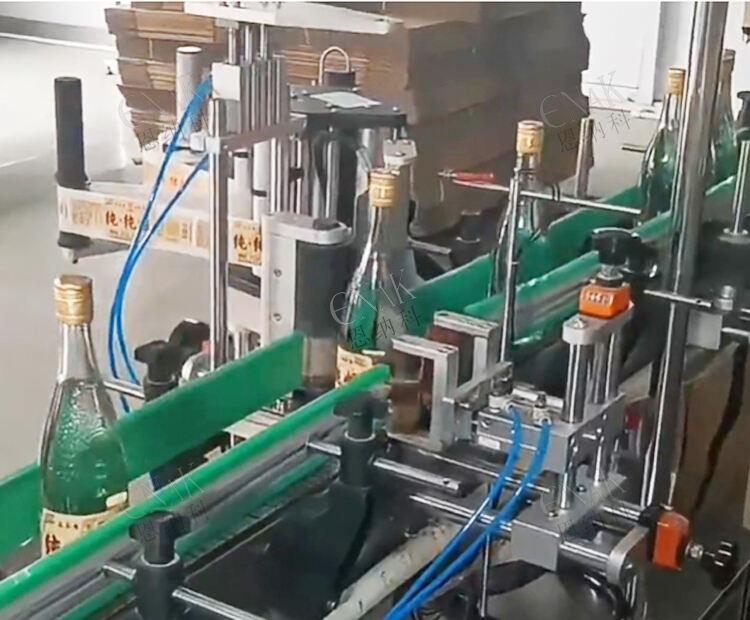

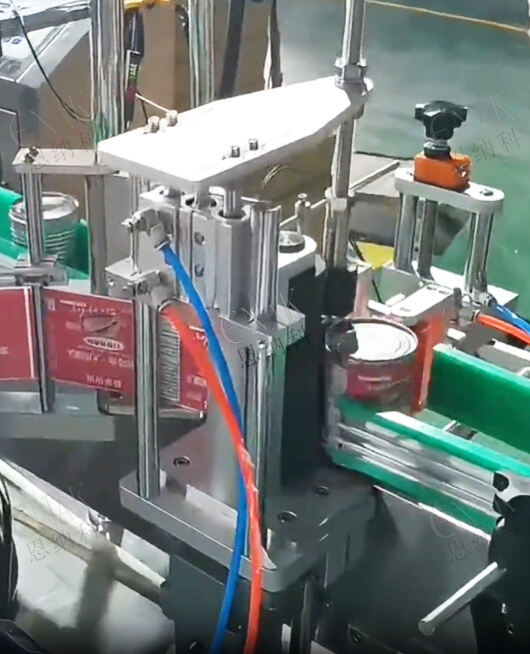

The Multifunctional Self-Adhesive Labeling Machine ENKB-09 is a cutting-edge solution designed to meet the diverse labeling needs of modern production lines. This automatic labeling machine offers exceptional versatility, applying labels accurately on various container shapes such as round bottles, square bottles, and flat bottles. Equipped with advanced automation technology, the machine significantly reduces manual labor while maintaining high productivity.

Key Features

Fully automatic operation ensures continuous workflow with minimal human intervention.

Supports a wide range of container shapes and sizes, making it perfect for beverage, pharmaceutical, chemical, and cosmetic industries.

High-speed labeling capability with a production rate tailored to industrial demands.

Sturdy construction with 304 stainless steel frame ensures durability and hygiene compliance.

Compatible with standard self-adhesive labels with maximum roll diameter of 330mm and width up to 190mm.

Performance Highlights

Precision labeling with error margin within ±1 mm guarantees professional quality output every time.

Stable and smooth label feeding mechanism to prevent label jams or misalignment.

Easy to operate with intuitive controls and prompt maintenance support.

Typical Usage Scenarios

Ideal for mass production lines requiring fast and consistent labeling of bottles.

Applicable in packaging for beverages, pharmaceuticals, chemicals, and personal care products.

Suitable for production environments where label accuracy and speed are critical.

| Parameter | Details |

| Model | ENKB-09 |

| Product Category | Multifunctional Automatic Self-Adhesive Labeling Machine |

| Minimum Order Quantity | 1 Unit |

| Price | USD 6000 |

| Machine Dimensions | (L) 2000mm × (W) 1280mm × (H) 1500mm |

| Gross Weight | 300 KG |

| Delivery Quantity | 1 Unit |

| Delivery Time | 40 Days |

| Packaging Method | Wooden Box |

| Power Consumption | 1.2 KW |

| Labeling Speed | 50 meters/minute |

| Voltage | AC 220V / 50HZ |

| Labeling Accuracy | ±1 mm |

| Body Material | 304 Stainless Steel |

| Compatible Container Types | PET Bottles, Glass Bottles, Square Bottles, Round Bottles |

| Label Type | Self-Adhesive Labels |

| Max Label Roll Diameter | 330mm |

| Max Label Width / Height | Width: 190mm, Height: Adjustable |

| Core Diameter (Paper Roll) | 76.2mm |

| Warranty Period | 3 Years |

| After-Sales Services | Video Support, On-Site Installation & Training, Online Support, Free Spare Parts |

Product Advantages

Automatic Operation Reduces Manual Labor

The Multifunctional Self-Adhesive Labeling Machine ENKB-09 is engineered for fully automated operation, allowing production lines to maximize efficiency while minimizing human labor costs. By automating the labeling process, operators can focus on other critical tasks, thereby improving overall productivity. The automatic feeding, positioning, and labeling mechanisms ensure seamless machine running without frequent manual adjustments.

High Precision Labeling with ±1mm Accuracy

Precision is critical for brand presentation and regulatory compliance. The Multifunctional Self-Adhesive Labeling Machine ENKB-09 achieves an outstanding labeling accuracy within ±1 millimeter. This precision dramatically reduces label wastage and product rework, ensuring that each container receives perfectly aligned labels. Such tight error control enhances the visual appeal of the products and upholds corporate quality standards.

Versatile Compatibility with Various Container Types

The Multifunctional Self-Adhesive Labeling Machine ENKB-09 supports a wide range of container shapes including round, square, and flat bottles. This versatility allows manufacturers to adapt quickly to different product lines without needing separate labeling equipment. Whether labeling PET bottles for beverages or glass bottles for pharmaceuticals, the machine provides consistent, reliable performance that meets diverse packaging requirements.

Production Process

The production of the Multifunctional Self-Adhesive Labeling Machine ENKB-09 combines advanced manufacturing technologies with strict quality control to ensure reliability and performance:

- Precision Machining of Components: Core mechanical parts such as gears, shafts, and frames are CNC-machined to exact tolerances, guaranteeing smooth operation and durability.

- 304 Stainless Steel Fabrication: The machine body is fabricated using food-grade 304 stainless steel, providing corrosion resistance and compliance with hygiene requirements for packaging.

- Automated Assembly Lines: Each Multifunctional Self-Adhesive Labeling Machine is assembled on automated lines to ensure consistent build quality and efficient manufacturing timelines.

- Software Integration and Testing: The machine’s PLC control system is programmed for precision label positioning and speed control. Comprehensive testing confirms the ±1mm labeling accuracy before delivery.

- Strict Quality Assurance: Every unit undergoes rigorous inspection procedures, including performance tests, safety checks, and packaging verification for secure shipment.

FAQ

What types of containers can the Multifunctional Self-Adhesive Labeling Machine ENKB-09 handle?

It can label round bottles, square bottles, and flat bottles made of PET or glass.

What is the labeling speed of the machine?

The machine achieves labeling speeds of up to 50 meters per minute.

How accurate is the labeling?

The labeling accuracy is within ±1 mm, ensuring high-quality application.

What maintenance support is provided?

We offer video technical support, on-site installation, commissioning, training, and free spare parts delivery.

What is the warranty period?

The machine comes with a standard 3-year warranty.

For inquiries about the Multifunctional Self-Adhesive Labeling Machine ENKB-09 or a personalized quotation, please contact us today. Our sales and technical team are ready to assist you.