Description

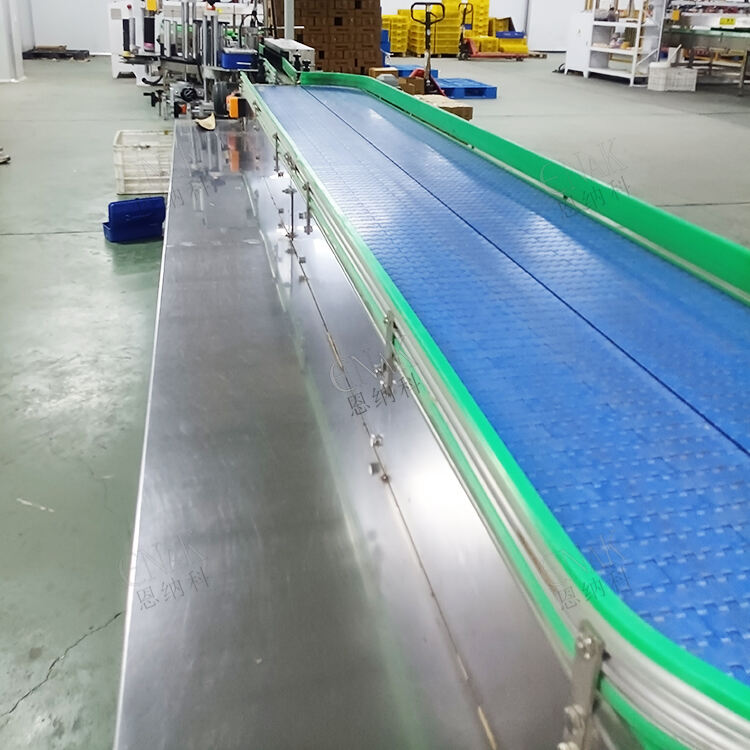

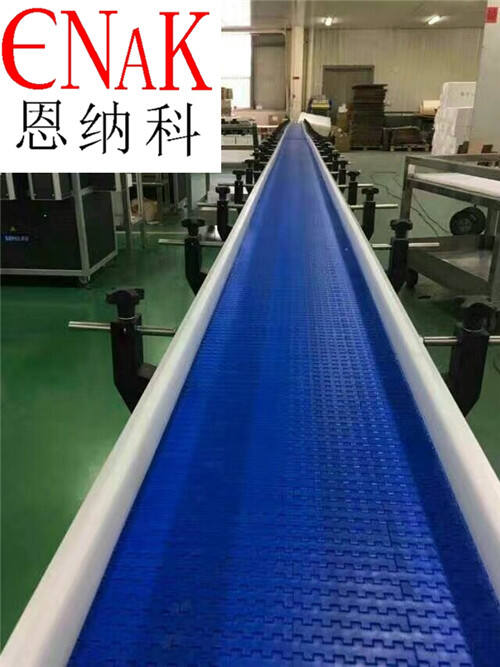

ENAK (Tianjin) Automation Equipment Co., Ltd offers the ENKS-04 Mesh Belt Automatic Conveyor System, a high-performance solution designed for industrial automation environments requiring efficient material transport. This system extends the capability of traditional conveyors by integrating mesh belt technology, providing durability and flexibility for a wide range of industrial applications.

Product Overview: The ENKS-04 features mesh belts made from stainless steel or high-strength alloys, suitable for applications requiring cooling, draining, or heat resistance. Its open structure allows materials to be transported with excellent air and liquid permeability.

Performance & Reliability: Built to maintain continuous operation under heavy loads, the mesh belt conveyor ensures smooth, consistent movement with low maintenance. Advanced drive systems support stable speeds tailored to specific production requirements.

Integration & Control: Equipped with cutting-edge automation interfaces, the conveyor integrates easily with industrial control systems including barcode and RFID readers for product tracking and sorting.

Safety & Hygiene: The open mesh design facilitates cleaning, making the system ideal for food processing, pharmaceutical, and manufacturing environments with strict sanitation standards.

Modular & Flexible: The system allows customizable lengths, widths, and configurations, easily adaptable to complex factory layouts.

User-Friendly Operation: Advanced control panels facilitate real-time monitoring and efficient troubleshooting to minimize downtime.

| Parameter | Value |

| Model | ENKS - 04 |

| Minimum Order Quantity | 1 - 4 meters: 600 |

| 5 - 9 meters: 500 | |

| More than 10 meters: 260 | |

| Price Step (USD) |

600 500 260 |

| Overall Dimensions | Customizable |

| Outer Packaging Dimensions | 1203X235X265 cm |

| Shipment Quantity | 1 |

| Estimated Shipment Time | 35 |

| Packaging Method | Wooden Case |

| Service | Free Replacement of Parts |

| Power | 0.75KW |

| Load Capacity | Customizable |

| Conveyor Width | Customizable |

| Material | PVC, PE, PU |

| Speed | Adjustable |

| Maximum Weight of Goods | Customizable |

| Applicable Products | Cartons, Pallet - boxes, Plastic Baskets, Bags, Large Barrels, Packaging Boxes |

| After - sales Service System | One - to - one Video Remote Guidance |

Product Advantages

Barcode / RFID Recognition Integration

ENKS-04 conveyors can be fitted with automatic barcode scanners or RFID readers along the conveyor line. This integration enables real-time tracking of work-in-progress items and finished goods, supporting automated sorting and quality control. The system's data management capabilities enhance traceability, inventory control, and operational transparency, meeting modern industrial digitalization requirements.

Comprehensive and Versatile Interfaces

Providing standardized interfaces like IO-Link, Ethernet/IP, and Profinet, ENKS-04 ensures rapid connection and interoperability within automated production environments. These interfaces facilitate smooth data flow between the conveyor and manufacturing execution systems (MES), programmable logic controllers (PLCs), robotics, and other peripheral devices. Quick setup and system communication reduce commissioning time and technical complexity.

Complete Safety Protection

The system includes multiple safety features such as emergency stop buttons, safety light curtains, protective guards, and pull-cord switches distributed along the conveyor. These devices ensure the immediate halt of operations in emergency scenarios to protect personnel from hazards. The design complies with international safety standards, minimizing workplace accidents and promoting a safe manufacturing environment.

Durable and Efficient Design

Mesh belts made of stainless steel or alloys provide excellent wear resistance and durability under high temperature, moisture, or corrosive conditions. The conveyor framework is engineered for rigidity and longevity, supporting heavy industrial use with minimal maintenance needs. The open mesh structure permits liquids and debris to pass through, reducing cleaning cycles and avoiding product contamination.

Flexible Applications

Thanks to the modular design, conveyor dimensions and configurations can be customized for straight, curved, inclined, or declined sections, catering to various factory layouts and process requirements. This adaptability enhances spatial efficiency and ensures operational continuity in dynamic industrial settings.

Operational Ease

With an intuitive user interface on the control panel, operators can monitor conveyor status, adjust operational speeds, and access diagnostic reports. This helps maintain optimal performance and quick resolution of any issues, lowering overall operational costs and downtime.

Energy Saving

The conveyor employs energy-efficient motors and intelligent speed control algorithms that optimize power usage in response to real-time production demand, supporting sustainable manufacturing initiatives.

Application Scenarios

The ENKS-04 Mesh Belt Conveyor System is widely applied across many industries:

Food Processing

Ideal for transporting baked goods, meat, poultry, seafood, and produce where ventilation, cooling, or drying are required during transport.

Pharmaceutical Manufacturing

Used for clean, hygienic transport of medicine containers under stringent contamination control.

Electronics Industry

Suitable for cooling electronic components or assemblies on the production line with precise control of airflow during transport.

Metalworking and Heat Treatment

Efficiently transports parts exposed to heat or machining fluids, allowing cooling or drainage.

Packaging and Sorting Facilities

Integrates with barcode/RFID tracking systems for seamless sorting, inventory management, and production tracing.

Automotive Parts Manufacturing

Moves components along diverse paths including inclines and curves with robustness and precision.

FAQ

Q1: What materials are used for the mesh belt?

A: Typically stainless steel or specially treated alloy materials designed for durability and hygiene.

Q2: Can the conveyor integrate barcode or RFID readers?

A: Yes, it supports integration with these technologies for automated tracking and sorting.

Q3: What safety features are included?

A: Emergency stops, light curtains, protective guards, and pull-cord switches are standard safety installations.

Q4: Is the conveyor flexible in layout?

A: Yes, modular design allows straight, curved, inclined, or declined configurations.

Q5: How energy efficient is the system?

A: The conveyor uses intelligent speed control and energy-efficient motors to minimize power consumption.

For comprehensive consulting and custom configuration of the ENKS-04 Mesh Belt Automatic Conveyor System, please contact ENAK (Tianjin) Automation Equipment Co., Ltd. Our specialists are prepared to assist you in designing an automated, efficient, and safe conveyor solution tailored to your production needs.

Please click the “Inquiry” button below or contact us directly to send your project details. We look forward to providing professional advice, pricing, and support to enhance your industrial automation.