Description

Operation Method:

This machine is operated via a Human-Machine Interface (HMI), providing intuitive control with support for both Chinese and English interfaces.

Labeling Performance:

The Glass Bottle Labeler achieves a labeling speed of up to 50 m/min and a labeling accuracy of ±1mm, ensuring precise labeling for every glass bottle.

Electrical Specifications:

Motor power supply: single-phase three-wire, AC 220V/50Hz, 3KW; control voltage: DC 24V.

Label Parameters:

Maximum label roll diameter: 330mm; maximum label width/height: 190mm; core diameter: 76.2mm. These specifications allow the Glass Bottle Labeler to handle a wide range of label sizes.

Machine Dimensions and Weight:

Dimensions: (L)3040mm × (W)1920mm × (H)1830mm; weight: 300KG.

Environmental Adaptability:

Operates reliably at altitudes of 3–2000 meters, temperatures from 0℃ to 40℃, and humidity levels of 40%–95%.

Conveyor System:

Chain height: 900 ± 50mm; chain width: 82.6mm. The stable conveyor ensures smooth bottle transport, avoiding tipping or collisions, which is essential for high-precision labeling.

| Item | Specification |

| Operation Mode | Human-Machine Interface (HMI) |

| Labeling Speed | 50 m/min |

| Labeling Accuracy | ±1 mm |

| Motor Power Supply | Single-phase three-wire, AC 220V / 50Hz, 3KW |

| Control Voltage | DC 24V |

| Max. Label Roll Diameter | 330 mm |

| Max. Label Width/Height | 190 mm |

| Core Diameter | 76.2 mm |

| Machine Dimensions | (L)3040 mm × (W)1920 mm × (H)1830 mm |

| Environmental Conditions | Altitude: 3–2000 mTemperature: 0℃–40℃Humidity: 40%–95% |

| Machine Weight | 300 KG |

| Conveyor Height | 900 ± 50 mm |

| Conveyor Width | 82.6 mm |

Product Advantages

High-Quality Materials and Ease of Operation

The Glass Bottle Labeler is constructed from food-grade 304 stainless steel and aluminum alloy, with surfaces treated via electrophoresis and oxidation for corrosion resistance and durability. Its modular design allows easy adjustments and rapid product changeover, accommodating diverse production requirements.

Intelligent Parameter Storage

The machine can store up to 10 sets of labeling parameters for different products. Operators only need to recall the relevant parameter set to switch between bottle types, reducing downtime and improving production efficiency.

Wide Applicability

The Glass Bottle Labeler is especially suitable for square glass bottles but also supports a variety of sizes and label types, including paper, film, and transparent labels. It is ideal for industries such as food, beverages, and pharmaceuticals, meeting diverse labeling needs.

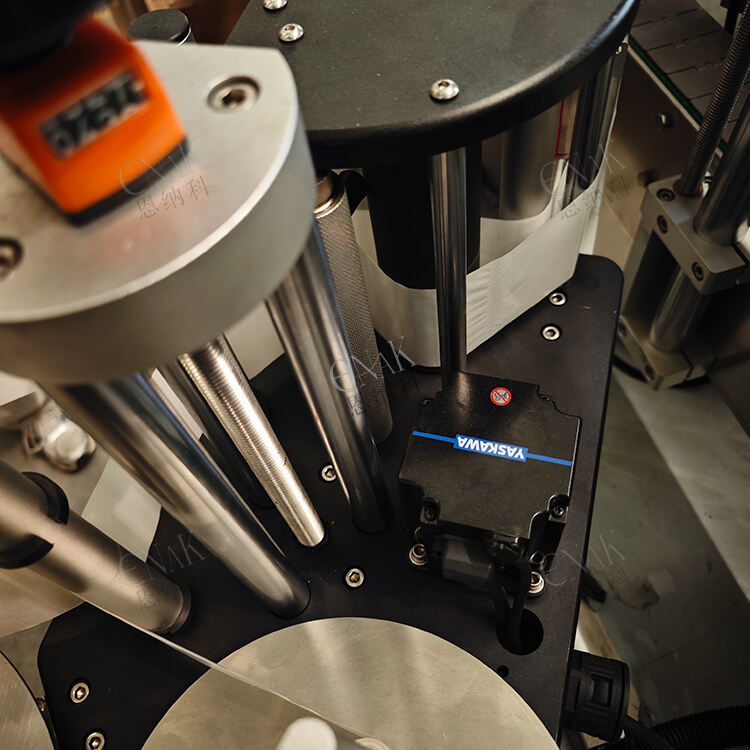

High Precision Labeling

With advanced servo control and HMI operation, the Glass Bottle Labeler maintains ±1mm labeling accuracy even at high speeds, ensuring every bottle is labeled consistently and neatly, enhancing product appearance.

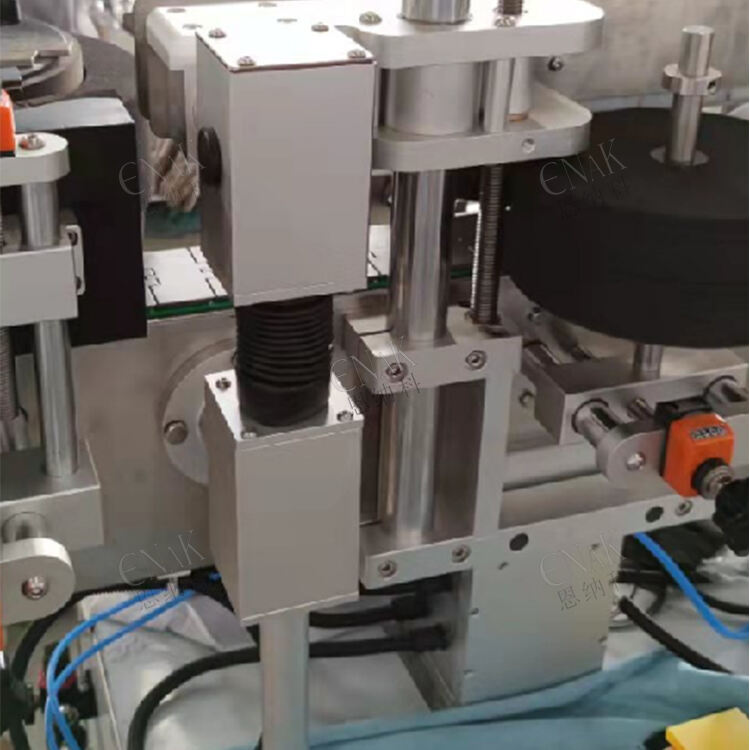

Stable and Reliable

The machine's high-rigidity structure, combined with high-performance transmission components and conveyor systems, allows the Glass Bottle Labeler to operate continuously for long periods with minimal downtime, supporting large-scale production lines.

After-Sales Service

Installation and Commissioning

Tianjin ENAK provides on-site installation and commissioning services to ensure the Glass Bottle Labeler integrates perfectly with your production line and operates smoothly.

Technical Training

After purchasing the Glass Bottle Labeler, we offer operation and maintenance training. Operators will quickly learn to use the Glass Bottle Labeler, optimizing production efficiency.

Warranty Service

The Glass Bottle Labeler comes with a one-year warranty for the entire machine, with extended warranty periods for key components. Our after-sales team responds promptly to any issues, ensuring the Glass Bottle Labeler remains fully operational.

Remote Support and On-Site Service

Customers have access to 24/7 remote technical support. If the Glass Bottle Labeler encounters operational or parameter adjustment issues, professional engineers provide immediate guidance. On-site service is available if necessary, quickly resolving problems.

Spare Parts Supply

Common wear parts for the Glass Bottle Labeler are available for long-term supply, preventing production interruptions and maintaining efficiency.

With comprehensive after-sales support, the Glass Bottle Labeler provides customers with peace of mind, stability, and high efficiency, ensuring every unit delivers maximum value.

FAQ

Q1: Can the Glass Bottle Labeler handle transparent labels?

A1: Yes. It is equipped with high-sensitivity photoelectric sensors that accurately detect and apply transparent labels.

Q2: Is changing bottle sizes complicated?

A2: Not at all. The Glass Bottle Labeler can store multiple parameter sets, allowing quick switching between different bottle types.

Q3: Is the machine suitable for high-volume production?

A3: Yes. With a high-rigidity structure and stable conveyor system, the Glass Bottle Labeler can run continuously under large-scale production without failure.

Q4: Does operation require specialized training?

A4: No. The intuitive and bilingual interface enables ordinary workers to quickly master the Glass Bottle Labeler.

If you are looking for a labeling solution that is high-precision, high-speed, and highly reliable,

the Glass Bottle Labeler is your ideal choice.

Please leave your inquiry information today. Our professional team at Tianjin ENAK Automation Equipment Co., Ltd. will contact you promptly to provide detailed specifications and customized solutions.