Description

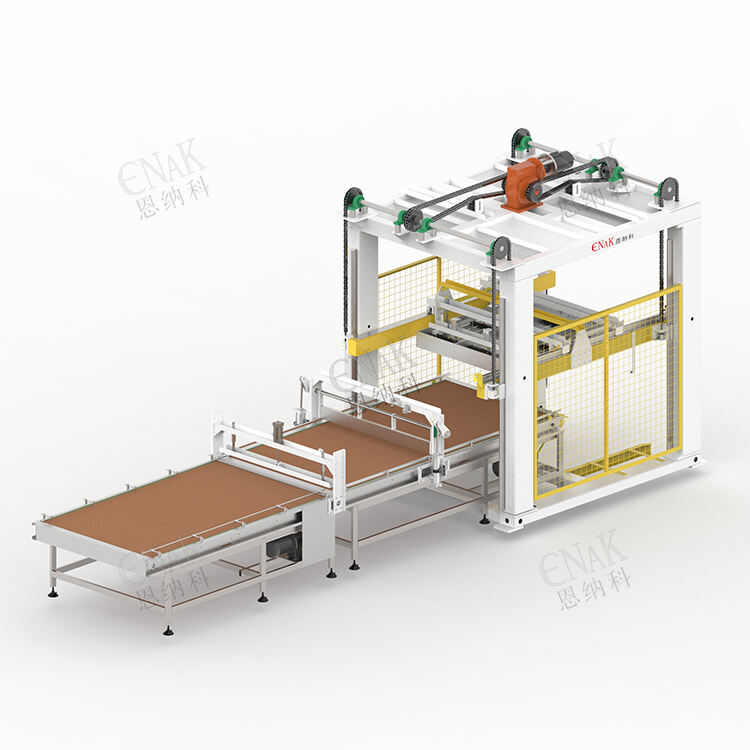

The ENKM-02 High Speed Automatic Meat Canned Palletizer Machine by ENAK (Tianjin) Automation Equipment Co., Ltd is an advanced automated palletizing solution designed specifically for meat canned products. This machine streamlines the palletizing process with high efficiency and precision, making it an essential part of modern meat processing and packaging lines.

Product Overview:

Designed for automated stacking of canned meat products, ENKM-02 supports high-speed palletizing, reducing manual labor and enhancing production consistency.

High Performance:

Capable of rapid, accurate stacking with minimal downtime, the machine supports continuous operation to meet demanding production schedules.

Smart Control:

Equipped with advanced servo motors and intelligent control systems, ENKM-02 ensures smooth, stable operation and tight stacking patterns.

Easy Integration:

The machine seamlessly integrates with upstream packaging equipment and downstream conveying systems, facilitating a fully automated production line.

Robust and Durable:

Constructed from high-grade materials, it is engineered for long-lasting, heavy-duty industrial use with minimal maintenance.

Improved Production Quality:

Automated palletizing reduces product damage caused by human handling, maintaining product integrity and appearance.

Safety Focused:

Designed with multiple safety features to protect operators and ensure safe operations during high-speed production.

| Parameter | Value |

| Model | ENKM - 02 |

| Minimum Order Quantity | 1 |

| Price Step (USD) | 25000 |

| Unit | Set |

| Overall Dimensions | 1203X235X265 |

| Outer Packaging Dimensions (cm) | 1203X235X265 |

| Gross Weight (KG) | 2500 |

| Shipment Quantity | 1 |

| Estimated Shipment Time | 45 |

| Packaging Method | Wooden Case |

| Service | Free Replacement of Parts |

| Power | 7KW |

| Voltage | 380V/50HZ |

| Body Material | Carbon Steel Baked Enamel |

| Load (KG) | 300 |

| Working Radius | 1750 |

| Palletizing Speed | 0 - 2 layers/min |

| Applicable Product Types | Tin - plate Canned Goods, Glass - bottle Canned Goods (with Iron Lids) |

| Pallet Size (MM) | L800-1300*W800-1200*H100-150 |

| Pallet Supply Method | Manual Placement/Automatic Placement |

| Warranty Period | 3 Years |

| After - sales Service System | Video Technical Support, On - site Guidance, On - site Installation, Commissioning and Training, Online Support, Free Spare Parts |

| Core Components | Motor, Pump, PLC, Engine, Gear, Bearing, Pressure Vessel |

Product Advantages

ENKM-02 offers distinct advantages that optimize production efficiency, safety, and product quality:

Multiple Safety Protections

The ENKM-02 is equipped with a comprehensive safety system, including sturdy safety fences, safety light curtains, emergency stop buttons, and collision sensors. These hardware protections work alongside software interlocks to create a fail-safe environment, ensuring absolute safety for operators during human-machine interactions. This rigorous safety framework complies with international safety standards and minimizes production risks.

Seamless Production Line Integration

To support Industry 4.0 and smart factory concepts, the ENKM-02 comes standard with communication interfaces such as Profinet, Ethernet/IP, and Modbus TCP. This enables smooth real-time data exchange with upstream packaging machines, downstream conveyor belts, and enterprise systems including MES (Manufacturing Execution System) and WMS (Warehouse Management System). Such seamless integration facilitates centralized monitoring, control, and optimization of the entire production process.

Enhanced Product Quality

Automating the palletizing process significantly reduces damages related to human fatigue, such as dents, drops, or misalignment in stacked canned meats. This ensures that products retain their pristine appearance throughout handling and shipping, protecting the brand’s reputation for quality. Consistent stacking patterns also improve pallet stability, reducing risks during transport.

High-Speed Efficiency

The advanced servo-driven palletizer can sustain rapid stacking rates suitable for high-volume canned meat production lines. Its precise and repeatable motion control enables quick placement of cans, maintaining continuous throughput while minimizing cycle times and production bottlenecks.

Robust Build for Continuous Operation

Built with high-quality industrial materials and components, the ENKM-02 is designed for demanding operational environments. It withstands the rigors of continuous 24/7 operation, reducing downtime and maintenance costs, and supporting long-term reliable performance in meat processing plants.

User-Friendly Interface and Maintenance

The system’s control panel features an intuitive touchscreen interface, allowing operators to easily monitor performance, adjust stacking parameters, and manage diagnostics. Modular design also enables prompt maintenance and part replacement, minimizing downtime and improving overall operational efficiency.

Application Scenarios

The ENKM-02 High Speed Automatic Meat Canned Palletizer Machine is widely applicable across various environments:

Meat Processing Plants

Specifically designed to handle canned meat products like beef, chicken, pork, and seafood cans. Automation maximizes productivity while maintaining product quality and safety standards.

Food Packaging Factories

Suitable for integration into high-capacity packaging lines where canned meat products require consistent stacking for shipment preparation.

Cold Storage and Distribution Centers

Automates palletizing for frozen or chilled canned meats, improving logistics efficiency and reducing manual labor in warehouse environments.

Retail and Wholesale Packaging Operations

Supports rapid palletizing for large-scale retail distribution, ensuring neat stacking that simplifies loading, unloading, and display.

Custom Packaging Lines

Compatible with mixed product palletizing where multiple sizes or packaging types of canned meat are handled, thanks to flexible program adjustments.

Frequently Asked Questions

Q1: What types of canned meat products can the ENKM-02 handle?

A: The palletizer is optimized for a wide range of canned meats including beef, chicken, pork, and seafood in various can sizes and shapes.

Q2: How fast can this machine palletize meat cans?

A: The ENKM-02 supports high-speed operation tailored to meet high-volume production demands, with precise cycle times that maximize throughput.

Q3: Can this palletizer connect with my existing production line?

A: Yes, it features standard communication interfaces like Profinet, Ethernet/IP, and Modbus TCP for seamless integration with upstream and downstream equipment and enterprise systems.

Q4: How is operator safety ensured during operation?

A: Multiple safety hardware and software mechanisms such as safety fences, light curtains, and collision sensors prevent accidents and ensure a secure working environment.

Q5: What maintenance is required for reliable operation?

A: The machine design supports easy modular maintenance with quick access to components. Routine checks and replacement of wear parts help ensure long-term reliability.

We warmly invite you to contact ENAK (Tianjin) Automation Equipment Co., Ltd for more detailed information about the ENKM-02 High Speed Automatic Meat Canned Palletizer Machine. Our expert team is ready to provide tailored automation solutions to fit your production requirements, enhancing efficiency, safety, and product quality.

Please click the “Inquiry” button below or reach out directly to share your specific project details and needs. We will promptly offer professional consultation, cost estimates, and after-sales support. Partner with ENAK to advance your smart manufacturing journey and achieve a safer, higher-quality, and more productive palletizing operation.