Description

Product Overview

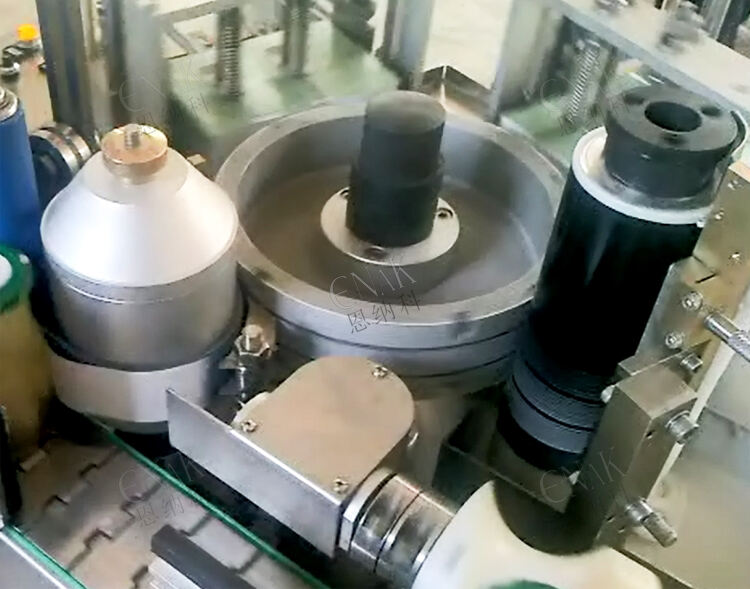

The High Accuracy Productivity Double - side rapid labeling machine ENKL - 04, developed by Tianjin ENAK, is a cutting - edge labeling solution designed to meet the high - demand labeling needs of modern manufacturing. It is engineered to apply labels on both sides of products with exceptional precision and speed.

Product Performance

This labeling machine offers remarkable accuracy with a precision of ±1 MM. It can achieve a high labeling speed, handling 40 - 240 items per minute, ensuring high productivity in various production scenarios. Its double - side labeling function streamlines the labeling process and saves time.

Use Scenarios

Suitable for a wide range of industries such as food, beverage, and pharmaceuticals, the ENKL - 04 is ideal for labeling products like bottles, cans, and boxes. In large - scale production lines where efficiency and accuracy are crucial, this machine can significantly improve the overall production process. It can also be used in medium - sized enterprises aiming to enhance their labeling operations.

Parameter |

Details |

Model |

ENKL - 04 |

Labeling Speed |

40 - 240 items per minute |

Power |

1KW |

Dimensions |

28008501100MM |

Package Dimensions |

1200X80X135CM |

Gross Weight |

650KG |

Precision |

±1 MM |

Applicable Label Type |

Various types of labels |

Applicable Product Types |

Bottles, cans, boxes, etc. |

Product Advantages

Support for Multiple Bottle Diameter Adjustments and Easy Model - changing

The ENKL - 04 is highly adaptable when it comes to different bottle diameters. It is equipped with an advanced adjustment mechanism that allows for quick and easy changes. Manufacturers often need to label products with various bottle sizes. With this machine, they can simply adjust the settings according to the specific diameter requirements. For example, in a beverage factory that produces different sizes of soft drink bottles, switching between labeling different bottle diameters can be done in a matter of minutes. This not only saves time but also reduces production downtime, improving overall efficiency.

High - strength Conveyor Belt with Wear Resistance and Long Service Life

The conveyor belt of the ENKL - 04 is made of high - strength materials. It is designed to withstand the rigors of continuous use in high - volume production environments. The wear - resistant property ensures that it can last for a long time without frequent replacements. In a busy food production line where the conveyor belt is in constant motion, a durable conveyor belt like this can reduce maintenance costs and interruptions. It also helps in maintaining a smooth and stable labeling process as the products are transported accurately to the labeling stations.

Use of International Standard Electrical Components for High Stability

The ENKL - 04 utilizes electrical components that meet international standards. These components are known for their reliability and long - term performance. By using such components, the machine can operate stably even in complex industrial environments. For instance, in a factory with high electrical interference, the international standard electrical components can ensure that the labeling machine functions properly without glitches. This high stability leads to consistent labeling quality and fewer production errors.

Production Process

Component Sourcing and Inspection

Tianjin ENAK carefully sources high - quality components for the ENKL - 04. Electrical components are procured from well - known international suppliers. Mechanical parts are made from top - grade metals. All components undergo strict inspection upon arrival at the factory to ensure they meet the required quality standards.

Assembly and Integration

Skilled technicians assemble the components with great precision. The conveyor system, labeling heads, and control units are integrated step by step. Special attention is paid to the alignment of the labeling heads to ensure accurate double - side labeling. Electrical wiring is done neatly and securely to avoid any potential electrical issues.

Testing and Quality Assurance

Before leaving the factory, the ENKL - 04 is put through comprehensive testing. Labeling accuracy, speed, and the functionality of all features are tested under different conditions. Any issues are promptly addressed. Only when it passes all the tests with flying colors is it approved for shipment to customers.

FAQ

Q: Can the ENKL - 04 label non - standard shaped products?

A: While it is mainly designed for regular - shaped products like bottles and cans, to some extent, it can be customized to label certain non - standard shaped products. Our engineering team will assess the feasibility and provide appropriate solutions.

Q: How often does the conveyor belt need to be replaced?

A: Due to its high - strength and wear - resistant nature, under normal operating conditions, the conveyor belt of the ENKL - 04 can last for several years. However, the actual replacement time may vary depending on the usage intensity.

Q: What is the warranty period for the ENKL - 04?

A: The ENKL - 04 comes with a 3 - year warranty. During this period, we will provide free maintenance and replacement of defective parts (subject to the terms and conditions of the warranty).

If you are interested in our High Accuracy Productivity Double - side rapid labeling machine ENKL - 04, please leave your inquiry information below. Our professional sales team will contact you promptly to discuss your specific requirements and offer you the best solution.