Fully Automatic Small Double Sided Detergent Flat Self-Adhesive Sticker Labelling Machine

Description

Product Overview:

The ENKB-08 Self-Adhesive Sticker Labelling Machine is a newly developed high-performance automatic labeling solution from Tianjin ENAK. Compared with conventional machines in the market, this model demonstrates superior performance in drive system, control technology, and user interface. It is designed to achieve both high speed and high precision, fully meeting the requirements of modern production lines.

Performance Comparison:

The ENKB-08 uses an ultra-low inertia servo motor, while most labeling machines still rely on stepper motors.

It employs a Siemens PLC control system, instead of the single-chip controllers commonly found in other models, ensuring greater stability and scalability.

Its human-machine interface (HMI) enables true digital control, not just basic data display, making operation more intelligent and user-friendly.

Conveying System:

The imported AC motor combined with a high-capacity frequency inverter ensures smoother and more stable bottle conveying. With an adjustable photoelectric sensor for product detection, the Self-Adhesive Sticker Labelling Machine achieves zero-delay and zero-gap labeling, which significantly increases speed and accuracy. In contrast, many traditional machines rely on delay-based control, which often leads to label misplacement when voltage fluctuates or conveyor loads change.

Performance Features:

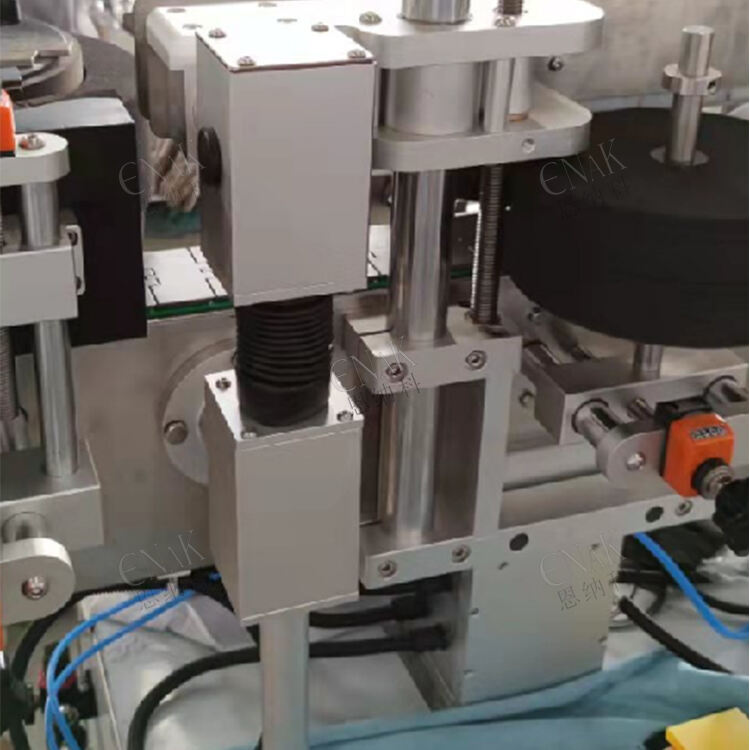

The labeling head supports eight-dimensional adjustments, enabling flexible adaptation to irregular bottles and challenging transparent labels. A high-elastic scraper and sponge roller eliminate bubbles during application. The enhanced rigid mechanical frame provides a clean design, strong stability, and reliable long-term performance.

| Item | Specification |

| Operation Mode | Human-Machine Interface (HMI) |

| Labeling Speed | 50 m/min |

| Labeling Accuracy | ±1 mm |

| Motor Power Supply | Single-phase three-wire, AC 220V / 50Hz, 3KW |

| Control Voltage | DC 24V |

| Max. Label Roll Diameter | 330 mm |

| Max. Label Width/Height | 190 mm |

| Core Diameter | 76.2 mm |

| Machine Dimensions | (L)3040 mm × (W)1920 mm × (H)1830 mm |

| Environmental Conditions | Altitude: 3–2000 mTemperature: 0℃–40℃Humidity: 40%–95% |

| Machine Weight | 300 KG |

| Conveyor Height | 900 ± 50 mm |

| Conveyor Width | 82.6 mm |

Product Advantages

Simple and Easy Operation

The Self-Adhesive Sticker Labelling Machine is equipped with a full-color touch HMI, offering intuitive parameter setting and logical navigation. Operators do not need extensive training to master the system. The bilingual (Chinese/English) interface makes the machine suitable for diverse production environments. Even first-time operators can quickly complete setup and production tasks, saving both time and labor costs.

Adaptability to Tapered Products

Many labeling machines struggle when handling tapered bottles, often causing misalignment or wrinkles. The ENKB-08 Self-Adhesive Sticker Labelling Machine solves this problem with a modular design—only a few parts need to be replaced to achieve precise labeling on tapered bottles. This feature reduces production line transformation costs and enhances flexibility for businesses dealing with multiple packaging formats.

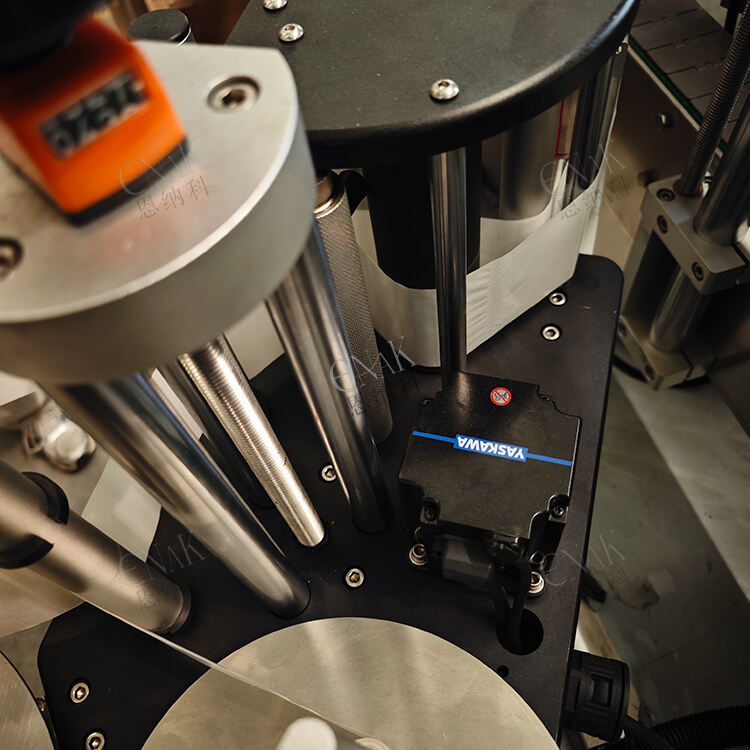

Eight-Dimensional Labeling Head

The eight-dimensional adjustable labeling head allows operators to manually fine-tune angles without the need for tools or screws. This design dramatically increases efficiency, reduces downtime during product changeovers, and ensures stable production. Even for complex or irregular bottle shapes, the Self-Adhesive Sticker Labelling Machine quickly finds the optimal labeling angle, maintaining high accuracy.

High Precision and Speed

Driven by servo motors and controlled by PLC closed-loop systems, the machine delivers labeling accuracy of 0.01 m/min, which is significantly higher than the 1 m/min accuracy level of traditional models. Labeling speeds can be digitally set within a wide range of 0.5–40 m/min, making the Self-Adhesive Sticker Labelling Machine adaptable to high-speed, large-scale production lines.

Reliability and Long Service Life

Built with a reinforced mechanical structure and imported components, the Self-Adhesive Sticker Labelling Machine maintains consistent stability even during extended high-speed operation. A photoelectric detection system continuously monitors bottle and label status, identifying missing bottles or labels in real-time to prevent waste.

In summary, the Self-Adhesive Sticker Labelling Machine offers ease of use, adaptability, high precision, and stable performance, making it the perfect choice for companies seeking to improve packaging efficiency and quality.

Production Scenarios

The Self-Adhesive Sticker Labelling Machine is widely used in various industries such as food, beverages, daily chemicals, and pharmaceuticals:

Beverage Industry: The Self-Adhesive Sticker Labelling Machine applies labels to juice bottles, mineral water bottles, and energy drink containers at high speed, improving line efficiency and brand presentation.

Edible Oil Industry: The Self-Adhesive Sticker Labelling Machine ensures accurate and smooth labeling for large-volume oil bottles, even under high-speed operation.

Daily Chemical Industry: For detergent, shampoo, and cleaning products, the Self-Adhesive Sticker Labelling Machine provides reliable performance on flat, oval, and irregular containers. Labels remain bubble-free and aligned.

Pharmaceutical and Healthcare Industry: The Self-Adhesive Sticker Labelling Machine supports precise labeling of small tapered bottles and square containers, meeting strict industry packaging standards.

Whether for mass production or small-batch multi-specification orders, the Self-Adhesive Sticker Labelling Machine delivers flexible performance with parameter storage and quick changeover functions. Its stability and adaptability make the Self-Adhesive Sticker Labelling Machine an essential core device in modern production lines.

By integrating advanced technology and reliable control, the Self-Adhesive Sticker Labelling Machine not only increases speed but also enhances overall product quality. For companies aiming to optimize efficiency, the Self-Adhesive Sticker Labelling Machine is an indispensable tool.

FAQ

Q1: Can the Self-Adhesive Sticker Labelling Machine handle transparent labels?

A1: Yes. It is equipped with high-sensitivity photoelectric sensors that accurately detect and apply transparent labels.

Q2: Does bottle changeover require complex adjustments?

A2: No. The Self-Adhesive Sticker Labelling Machine supports multi-parameter storage, allowing quick one-click switching.

Q3: Is it suitable for irregular or tapered bottles?

A3: Absolutely. The eight-dimensional labeling head enables rapid manual adjustments without extra tools, ensuring precise labeling.

Q4: Do operators need specialized training?

A4: Not necessary. With its intuitive and bilingual interface, the Self-Adhesive Sticker Labelling Machine can be quickly mastered by ordinary workers.

If you are looking for a labeling solution that offers high precision, high speed, and strong adaptability,

the Self-Adhesive Sticker Labelling Machine is your ideal choice.

Please leave your inquiry information today. The professional team at Tianjin ENAK Automation Equipment Co., Ltd. will contact you promptly to provide detailed specifications and customized solutions.