Description

Product Overview

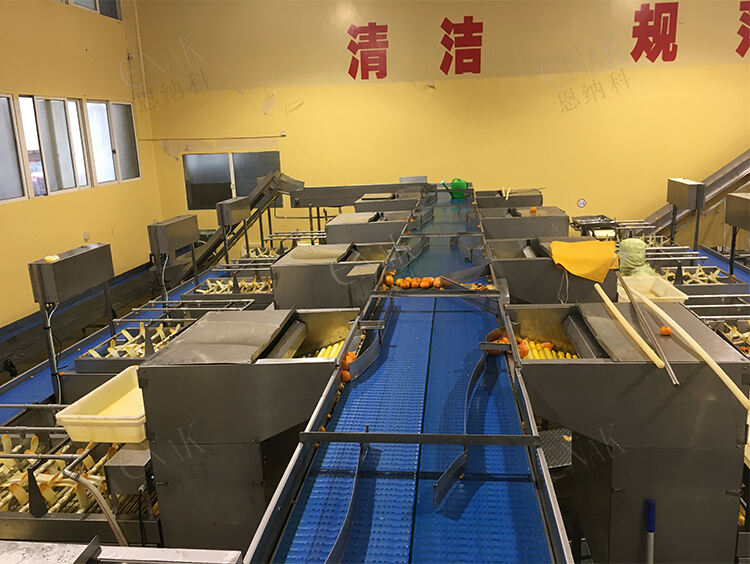

The Electric Automatic Stainless Steel Citrus Orange Peeler Machine ENKBP-01, developed by ENAK (Tianjin) Automation Equipment Co., Ltd., is a high-performance peeling machine designed for efficient citrus peeling. With an overall dimension of L1935W1159H1942mm, it fits well in commercial spaces like factories and fruit processing workshops. The outer packaging size is 80X90X120 cm, and the gross weight is 200 KG, ensuring safe transportation via wooden box packaging. This peeling machine is built to meet large-scale peeling needs, offering reliable performance for long-term use.

Product Performance & Service

This peeling machine operates stably, delivering consistent peeling results for citrus fruits like oranges. The estimated delivery time is 15 days, allowing customers to receive the peeling machine promptly. Moreover, ENAK provides a valuable service of free replacement of parts, ensuring minimal downtime if any component issues arise. Its stainless steel construction enhances durability, resisting corrosion and wear, which extends the service life of the peeling machine. Whether for continuous industrial production or regular commercial use, this peeling machine maintains efficient operation.

| Attribute | Value |

| Model | ENKBP-01 |

| Min. Order Qty | 1--9 |

| >10 | |

| USD Price (Tiered) | 7000 |

| 6600 | |

| Machine Size | L1935W1159H1942mm |

| Package Size | 80X90X120 cm |

| Gross Weight | 200 KG |

| Shipping Quantity | 1 |

| Estimated Lead Time | 15 (Days) |

| Packaging | Wooden Case |

| Service | Free Parts Replacement |

| Power | 0.75kw |

| Voltage | 380V/Customized |

| Application | Orange Processing |

| Material | 304 Stainless Steel |

| Peeling Rate | 97% |

Product Advantages

Easy Operation

This peeling machine features a user-friendly design with either a touch panel or button operation, making it simple for anyone to use. The intuitive interface eliminates the need for extensive training, allowing workers to master the peeling machine quickly. By simplifying the operation process, it reduces reliance on skilled labor, thereby lowering labor costs significantly. For businesses, this means less time spent on training and more time focused on improving overall production efficiency with the peeling machine. Even during peak production periods, the easy operation ensures smooth operation of the peeling machine without delays.

High Safety

Safety is a top priority for this peeling machine. It is equipped with safety protection devices and a protective cover to prevent accidents during operation. The protective cover shields the moving parts of the peeling machine, avoiding direct contact with operators. The safety protection devices automatically stop the peeling machine if any abnormal situation is detected, such as foreign objects entering the machine. This not only protects the operators from harm but also prevents damage to the peeling machine itself, ensuring a safe working environment for all users of the peeling machine.

Energy Conservation & Environmental Protection

The peeling machine adopts an optimized motor and transmission design, which effectively reduces energy consumption. Compared to traditional peeling equipment, it uses less electricity while maintaining high peeling efficiency, cutting down on energy costs for businesses. Additionally, the machine’s design minimizes waste generation during the peeling process. It ensures maximum utilization of citrus fruits, reducing the amount of discarded peel and pulp, which aligns with environmental protection goals. This makes the peeling machine a sustainable choice for businesses looking to reduce their environmental footprint.

Operation Guide

Preparation

Before using the peeling machine, check if all parts are intact and properly installed. Ensure the power supply matches the machine’s requirements. Clean the feeding area and peeling components to avoid contamination. Place the citrus fruits to be peeled in a nearby container for easy loading into the peeling machine.

Start & Operation

Turn on the power switch of the peeling machine. Use the touch panel or buttons to select the appropriate peeling mode based on the type of citrus. Gently feed the citrus fruits into the machine’s feeding port one by one. The peeling machine will automatically start the peeling process, and you can monitor the progress through the transparent part of the protective cover.

Shutdown & Cleaning

After peeling is completed, press the stop button to turn off the peeling machine. Disconnect the power supply. Remove the peeled citrus fruits and clean the machine’s internal and external surfaces. For detachable parts, disassemble them and clean thoroughly, then reassemble for the next use of the peeling machine.

FAQ

Question: What should I do if the peeling machine stops working suddenly?

Answer: First, check if the safety protection device is triggered. If so, remove any foreign objects and reset the device. If the problem persists, contact our after-sales team, and we will guide you through troubleshooting or arrange free part replacement if needed.

Question: Can this peeling machine handle other fruits besides oranges?

Answer: This peeling machine is mainly designed for citrus fruits like oranges. While it may work for similar small citrus varieties, it is not recommended for non-citrus fruits to ensure optimal peeling performance of the peeling machine.

Question: Is there any maintenance required for the peeling machine?

Answer: Regularly clean the machine after use. Every 3 months, check the motor and transmission parts, and lubricate them if necessary. Our team also provides maintenance guidance to keep the peeling machine in good condition.

If you are interested in the Electric Automatic Stainless Steel Citrus Orange Peeler Machine ENKBP-01, please leave your inquiry information. We will respond to you promptly, providing detailed quotes and technical support to help you get the most suitable peeling machine for your needs.