Industry Pain Points

In today’s fast-paced manufacturing environment, packaging has evolved from a simple operational step to a critical factor affecting product safety, brand image, and operational efficiency. Many manufacturers struggle with inconsistent packaging quality, excessive labor costs, and limited adaptability when handling diverse carton sizes. Traditional manual or semi-automatic sealing processes often result in uneven sealing, damaged boxes, and compromised protection for transported goods. According to industry reports, approximately 30% of packaging defects in mid- to large-scale factories are related to improper sealing, leading to returns, complaints, and increased operational costs.

Another challenge lies in the growing diversity of products and carton specifications. Manufacturers increasingly face the need to package items ranging from lightweight consumer goods to heavy industrial products. A single-line packaging system must handle multiple carton dimensions without extensive downtime for adjustments. Manual intervention in this context not only reduces production efficiency but also increases the risk of human error.

Sustainability and cost efficiency are additional concerns. Excessive adhesive usage, high energy consumption, and frequent maintenance can impact both operational budgets and environmental targets. The industry is seeking solutions that reduce waste, optimize throughput, and maintain consistent product presentation.

In this context, carton sealing automation emerges as a critical investment. By standardizing the sealing process, manufacturers can maintain high-quality output, reduce labor dependence, and ensure that packaging meets both internal standards and external regulatory requirements. Tianjin ENAK’s carton sealing equipment addresses these pain points by offering a reliable, adaptable, and high-efficiency solution capable of supporting modern manufacturing needs.

Product Features and Solution Analysis

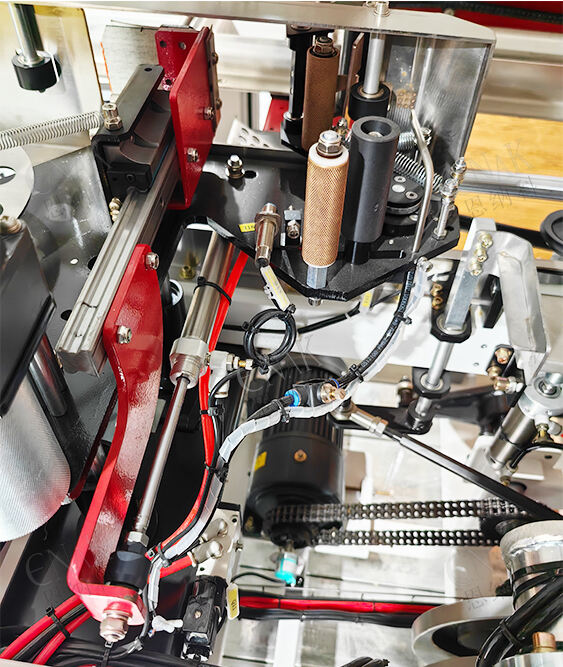

Tianjin ENAK’s carton sealing equipment distinguishes itself through a combination of technical precision, operational reliability, and adaptability. One of the key features is its ability to produce uniform, flat, and aesthetically pleasing tape seals. This is achieved through an advanced tape feeding and cutting mechanism that ensures each carton is securely closed, preventing leaks or structural compromise. For manufacturers, this translates into reduced product damage during storage and transport, enhanced brand perception, and fewer returns.

Another significant advantage is the equipment’s compatibility with various carton sizes. The carton sealing equipment can be adjusted quickly to accommodate different box heights, lengths, and widths without halting production for extended periods. Sensors and adaptive control systems automatically detect carton dimensions, aligning the sealing mechanism to ensure optimal tape placement. This capability is particularly valuable for factories producing multiple product lines or seasonal packaging variations, as it reduces the need for multiple machines or manual adjustments.

Customization support is another pillar of Tianjin ENAK’s solution. The carton sealing equipment can be tailored to meet specific industry requirements, including reinforced sealing for heavy cartons, integration with upstream and downstream packaging lines, or specialized adhesive types. Customization ensures that manufacturers do not compromise efficiency or quality when handling niche products. Additionally, the machine’s modular design facilitates easy upgrades and maintenance, reducing downtime and extending operational lifespan.

By integrating these features, Tianjin ENAK provides a holistic solution that improves operational efficiency, reduces labor costs, and enhances packaging quality. The carton sealing equipment serves as both a productivity enhancer and a quality assurance tool, aligning with modern production demands and market expectations. With automated, precise, and reliable sealing, factories can achieve higher throughput while maintaining consistent packaging standards.

Enterprise Customization Capabilities

Customization is critical in modern manufacturing, as product diversity and market demands require flexible packaging solutions. Tianjin ENAK’s carton sealing equipment stands out in this regard due to its comprehensive approach to enterprise-specific configurations. Manufacturers are no longer restricted to one-size-fits-all machinery; instead, they can collaborate with ENAK engineers to design equipment that meets precise operational, product, and facility requirements.

For example, factories producing fragile items often require reinforced sealing and precise tape alignment to prevent carton collapse during transport. ENAK’s carton sealing equipment can be configured with high-precision tape applicators, pressure adjustment mechanisms, and anti-slip carton conveyors to ensure maximum stability. Conversely, factories handling lightweight goods may prioritize speed and minimal adhesive usage, which can be addressed through optimized motor settings, rapid tape feeding systems, and efficient energy management.

ENAK also supports integration with existing production lines. The carton sealing equipment can be linked with automated carton erectors, conveyors, and labeling systems, creating a seamless packaging workflow. This interoperability allows manufacturers to maintain continuous operations, minimize manual intervention, and optimize overall equipment effectiveness (OEE). For facilities with multiple production lines, standardized sealing systems simplify maintenance and spare parts management while ensuring consistent packaging quality across all lines.

Moreover, the company provides software customization, including PLC control interfaces, touchscreen operation, and real-time monitoring capabilities. These features enable operators to manage multiple parameters, such as tape type, speed, and carton dimensions, from a single control panel. Data from the machine can be logged for performance analysis, predictive maintenance, and process optimization, providing actionable insights that support strategic decision-making.

The modular and customizable nature of Tianjin ENAK’s carton sealing equipment ensures that manufacturers of all sizes—from small enterprises to large-scale operations—can implement automated sealing solutions tailored to their needs. By aligning machine capabilities with production demands, ENAK empowers manufacturers to achieve higher efficiency, reduced waste, and improved product protection, positioning the carton sealing equipment as a versatile and future-proof investment.

Success Case Analysis

A mid-sized consumer goods manufacturer recently integrated Tianjin ENAK’s carton sealing equipment into its primary packaging line. Before implementation, the factory relied on semi-automatic sealing, which led to inconsistent tape alignment, frequent carton damage, and high labor costs. After introducing ENAK’s solution, the plant reported a 35% increase in packaging efficiency and a significant reduction in product returns due to damaged boxes.

The adaptive size detection and automated tape application ensured flawless sealing for multiple carton dimensions, including seasonal and promotional packaging variations. Operators highlighted the intuitive PLC interface and minimal manual adjustments as key factors in reducing downtime and simplifying training for new staff. Additionally, the machine’s high reliability decreased maintenance interventions, allowing production to maintain continuous operation during peak seasons.

In another example, a specialty food producer leveraged ENAK’s customization options to integrate reinforced sealing for heavy cartons containing glass jars. The carton sealing equipment’s adjustable pressure and precise tape alignment minimized carton failure, protected fragile contents, and enhanced customer satisfaction. By combining adaptability, automation, and robust design, Tianjin ENAK enabled these manufacturers to achieve measurable operational improvements and ensure high-quality packaging standards.