In modern beverage and food manufacturing, the label on a bottle is more than a simple identifier. It carries brand image, regulatory information, and key details that influence purchasing decisions. An automatic water bottle labeling machine must therefore do more than apply labels quickly; it needs to place them accurately on different bottle shapes, operate stably at high speed, and simplify changeovers between products.

Tianjin ENAK, a professional automation equipment manufacturer in China, has developed the Fruit Juice Oil Bottle Automatic Double Self-adhesive Labeling Machine to meet these demands in real production environments. This equipment is designed for square and oval bottles used for fruit juice, edible oil, and similar liquid products, and it can also serve as an automatic water bottle labeling machine for compatible bottle types. It combines precise control, flexible adjustment, and user-friendly operation to help manufacturers improve efficiency and labeling quality across multiple product lines.

|

|

Precision Labeling Performance Built for Demanding Production Lines

For many factories, the greatest challenge in bottle labeling is not only speed, but also maintaining accuracy and consistency over long shifts. The automatic double self-adhesive labeling machine from Tianjin ENAK is equipped with a closed-loop control system based on a PLC and a 750 W servo motor, allowing it to achieve high repeatability in label feeding and positioning. The label feeding speed control accuracy reaches approximately 0.01 m per minute, which is much finer than the commonly mentioned 1 m per minute level in typical labeling systems.

The machine’s labeling accuracy is about ±1 mm, which is important for products such as bottled water, fruit juice, and edible oil where misalignment is easy to notice on transparent or light-colored packaging. A deviation of just a few millimeters can cause labels to appear crooked relative to bottle edges or seams, affecting shelf presentation. By maintaining tight control of label position, Tianjin ENAK’s automatic water bottle labeling solution supports the visual quality expectations of brand owners and retailers.

The labeling speed can reach around 50 m per minute, with an adjustable output range from roughly 0.5 to 40 m per minute. This means manufacturers can adapt the line speed to match upstream filling and capping equipment. For example, a water bottling line operating at medium speed can set a matching labeling speed to avoid bottlenecks, while a faster juice line can push labeling closer to its higher range when needed.

Flexible Mechanical Design for Square, Oval, and Specialty Bottles

Traditional automatic water bottle labeling machines were often optimized for only one bottle shape, usually a round PET bottle. However, beverage and food producers now commonly use square, flat, and oval containers to differentiate their products. Tianjin ENAK’s Fruit Juice Oil Bottle Automatic Double Self-adhesive Labeling Machine is tailored for square and oval bottles used in fruit juice and edible oil packaging, and its structure can also support suitable water bottle formats with similar geometry.

The machine uses a conveyor with a height of about 900 ± 50 mm and a width of 82.6 mm, making it compatible with typical beverage and edible oil production lines. Its overall dimensions of approximately 3040 mm in length, 1920 mm in width, and 1830 mm in height, along with a weight of about 300 kg, provide a compact yet stable footprint for integration into existing line layouts. These specifications make it possible to upgrade or add labeling capability without needing a complete reconfiguration of the plant.

An eight-dimensional adjustable labeling head provides fine positioning capability in multiple directions and angles. Operators can adjust the labeling head to match the front and back surfaces of square bottles, the curved sides of oval bottles, or other special profiles. This level of mechanical flexibility helps one machine serve different bottle designs, which is particularly valuable for manufacturers who bottle water, juice, and oil products on related production lines.

Advanced Label Feeding and Tension Control for Smooth Label Surfaces

Achieving a smooth, wrinkle-free label surface depends heavily on label feeding and tension. Tianjin ENAK’s automatic double self-adhesive labeling machine includes a dual-roller label feeding mechanism. Before labels are dispensed onto the bottle, they pass through an active pressure roller that flattens the label material, helping to remove waves or slack in the web.

To maintain stable tension, the equipment uses a two-stage spring-type clutch combined with a belt brake. This design provides constant tension even at high speeds, reducing the risk of label stretching, tearing, or uneven movement on the web path. Stable tension is especially important when using thin film or transparent labels, which are common on water bottles and juice bottles and are more prone to visible defects when mishandled.

By managing label flatness and tension together, the machine lowers the chance of wrinkles, bubbles, and misaligned edges. This directly affects the final appearance of products on store shelves. For brands that compete in crowded markets, a clean, smooth label can support a “high-quality” impression and help encourage sales.

Eight-Dimensional Labeling Head for Fast Product Changeovers

In many beverage and food operations, production does not run the same product all day. There may be a small bottle of flavored water in the morning, a larger square juice bottle in the afternoon, and a flat edible oil container on another shift. A key strength of Tianjin ENAK’s automatic double self-adhesive labeling machine is the eight-dimensional adjustable labeling head, which enables quick adaptation to new bottle types without major mechanical changes.

Operators can adjust the labeling head position up, down, left, right, forward, backward, and adjust its angle to align with different label panels on various containers. When combined with the machine’s ability to store parameter sets for different products in the human-machine interface, this feature allows fast changeovers. Instead of disassembling or replacing large components, the operator recalls a stored recipe for a specific bottle and label combination, then performs fine adjustments as needed.

This approach reduces changeover time and supports flexible, multi-product production. For manufacturers, it means a single automatic water bottle labeling machine can work across several products with reduced downtime and less reliance on highly specialized adjustment skills.

High-Elastic Scraper and Sponge Rollers for Bubble-Free Labeling

Even when labels are fed accurately and placed correctly, air trapped under the label can create bubbles, wrinkles, or incomplete adhesion. To address this, Tianjin ENAK’s machine uses a high-elastic scraper and sponge rollers after label application. These components press the label firmly against the bottle surface, guiding trapped air out from under the label and ensuring full contact.

This detail is important for premium products with transparent labels or high-gloss printed labels. On such surfaces, even small bubbles or creases can be very visible. For bottled water and fruit juice products, where consumers often see the whole bottle, a neat label finish contributes directly to perceived product quality.

By combining controlled label feeding with mechanical pressing, the machine offers a complete approach to surface quality, not just basic adhesion.

Smart Human-Machine Interface Supporting Efficient Operation

Efficient operation of labeling equipment depends not only on hardware but also on how easily operators can control and monitor the system. Tianjin ENAK’s automatic double self-adhesive labeling machine uses a color human-machine interface that centralizes main operating parameters such as speed, label position, and sensor settings. The interface allows operators to start and stop the machine, adjust settings, and monitor status without manually adjusting individual hardware components.

Multiple parameter sets can be saved and recalled through the interface. For example, one set may correspond to a square edible oil bottle with large front and back labels, another to an oval juice bottle with different label size and position. When switching products, an operator selects the appropriate parameter set, which reduces manual data entry and lowers the risk of configuration errors.

Furthermore, the interface supports both Chinese and English, making it suitable for users in China and international plants where staff may prefer English-language menus. This bilingual capability simplifies training and daily use, supporting efficient operation in diverse production environments.

Reinforced Structure and Stable Running for Continuous Production

Continuous production in beverage and food factories demands equipment that runs reliably for long periods. Tianjin ENAK’s labeling machine incorporates an enhanced rigidity frame to support stability at operating speeds up to 50 m per minute. The machine’s weight of about 300 kg helps reduce vibration, which can otherwise affect labeling accuracy and increase mechanical wear.

A simple and robust structure also means fewer points of potential failure and easier maintenance. The motor power requirement of around 3 kW at AC 220 V, 50 Hz, with a 24 V DC control system, aligns with standard industrial power supplies. For many plants, this reduces installation complexity and electrical adaptation costs.

Environmental operating conditions cover altitudes roughly from 3 to 2000 meters, temperatures from 0℃ to 40℃, and humidity from about 40% to 95%, making the machine suitable for a wide range of typical factory environments as long as standard industrial conditions are respected.

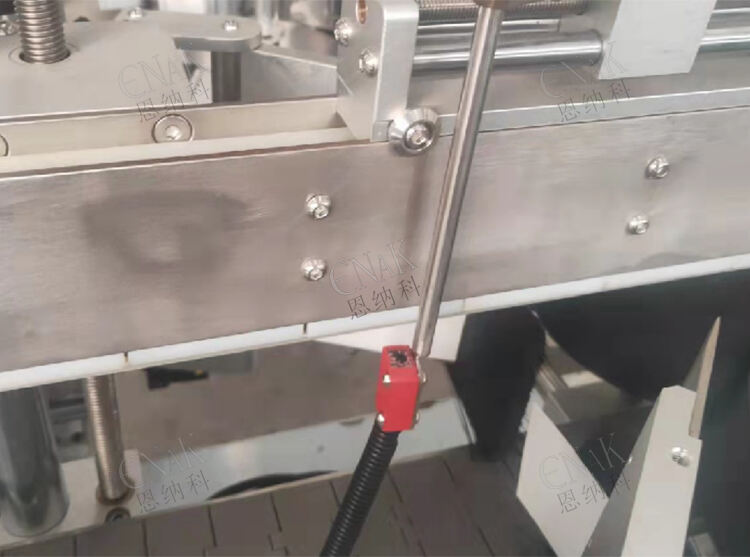

Integrated Detection to Reduce Label and Bottle Waste

Modern labeling machines benefit from integrated detection systems that help maintain quality and minimize waste. In Tianjin ENAK’s automatic double self-adhesive labeling machine, sensors are installed to monitor bottles and labels during the production process.

Bottle detection ensures that labels are only dispensed when a bottle is in position. If a gap is detected on the conveyor, the control system can prevent label application, helping avoid labels sticking to the conveyor or being wasted. Label detection can also identify missing labels on the label web and help stop production or trigger an alert so that operators can respond quickly.

For manufacturers, these detection capabilities reduce material losses and the number of incorrectly labeled products. This improves production yield and lowers costs in high-volume applications such as bottled water, fruit juice, and edible oil.

Application Across Bottled Water, Juice, and Edible Oil Production

Although the equipment name highlights fruit juice and edible oil applications, its technical features make it suitable for a wide array of bottle labeling tasks. In practice, this automatic double self-adhesive labeling machine can serve:

- As an automatic water bottle labeling machine for square or flat bottles commonly used in premium or flavored water lines,

- As a dual-side labeler for fruit juice and tea beverages packaged in special-shaped PET or glass bottles,

- As a front-and-back labeler for edible oil in square or rectangular bottles where accurate alignment of information and branding is essential.

The adjustable speed range, eight-dimensional labeling head, and stored parameter sets allow the same machine to support multiple product lines with minimal transition time. This flexibility helps manufacturers increase equipment utilization and reduce investment in separate machines for each product.

Tianjin ENAK’s Experience in Food and Packaging Automation

Tianjin ENAK was founded in 2012 and focuses on turnkey projects for pre-made meal production lines, canned food production lines, and back-end packaging production lines. The company integrates research and development, design, manufacturing, sales, and after-sales service, and has developed a broad portfolio of equipment that covers deep learning inspection systems, canned food processing machines, and packaging machines including self-adhesive, paste, and hot-melt glue labeling machines.

By offering related equipment such as depalletizers, bottle washers, fillers, sterilizers, case packers, sealers, palletizers, and other automation solutions, Tianjin ENAK is able to supply complete production concepts rather than only stand-alone machines. This makes it easier for customers to plan whole-line upgrades and maintain consistent performance across process steps.

With more than ten years of customization experience and a senior engineering team, the company serves manufacturers that seek high-quality equipment, support for installation and commissioning, and reliable after-sales service. For producers looking for an automatic water bottle labeling machine that can also serve juice and oil lines, the Fruit Juice Oil Bottle Automatic Double Self-adhesive Labeling Machine provides a technically advanced and flexible option backed by project experience in the food and packaging industries.

Table of Contents

- Precision Labeling Performance Built for Demanding Production Lines

- Flexible Mechanical Design for Square, Oval, and Specialty Bottles

- Eight-Dimensional Labeling Head for Fast Product Changeovers

- High-Elastic Scraper and Sponge Rollers for Bubble-Free Labeling

- Smart Human-Machine Interface Supporting Efficient Operation

- Integrated Detection to Reduce Label and Bottle Waste

- Application Across Bottled Water, Juice, and Edible Oil Production

- Tianjin ENAK’s Experience in Food and Packaging Automation