Product Background

In modern manufacturing environments, production lines face increasing pressure to improve efficiency while maintaining product quality. Packaging is a critical component of the supply chain, as it not only protects products during transportation but also influences customer perception and operational costs. Traditional manual or semi-automatic packing solutions often struggle to keep up with the speed and precision demanded by today’s high-volume production lines. Delays, inconsistent packaging, and equipment downtime can lead to increased labor costs, wasted materials, and bottlenecks in production.

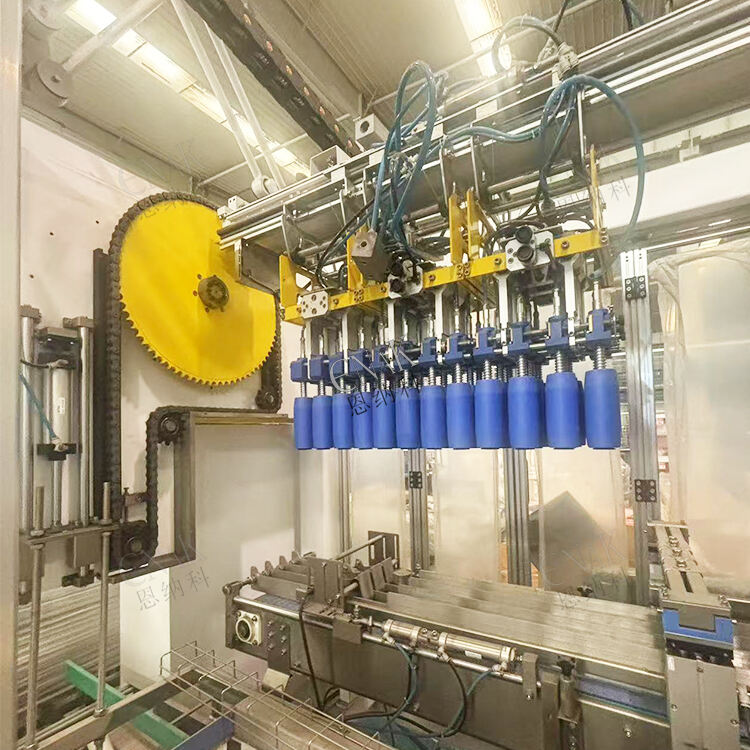

To address these challenges, Tianjin ENAK has developed the automatic packer, a machine designed to optimize both packaging speed and accuracy. The automatic packer integrates advanced mechanical design with precise automation controls, enabling manufacturers to handle a variety of packaging sizes and types with minimal human intervention. By automating repetitive packing tasks, the automatic packer not only reduces the risk of human error but also ensures consistent quality across batches.

From a project management perspective, implementing the automatic packer represents a strategic investment in production line efficiency. Industry research indicates that automated packing systems can increase throughput by up to 35% compared with traditional methods, while simultaneously reducing labor dependency and material waste. This positions the automatic packer as an essential tool for manufacturers aiming to improve operational performance, meet tight delivery schedules, and maintain high customer satisfaction.

Moreover, the automatic packer is designed with reliability in mind, featuring durable components and stable operation even under continuous high-speed conditions. Its compatibility with diverse packaging formats makes it suitable for a wide range of industries, including food and beverage, pharmaceuticals, and consumer goods. As production lines evolve toward more intelligent and flexible systems, the automatic packer provides the necessary foundation for both immediate efficiency gains and long-term operational scalability.

Product Features and Advantages

The automatic packer offers several technical advantages that directly enhance production line speed and accuracy. Key features include high-speed automated packing, compatibility with multiple packaging formats, and stable operational reliability.

High-Speed Automated Packing

One of the most significant advantages of the automatic packer is its ability to perform high-speed automated packing. Equipped with precise timing mechanisms and synchronized conveyors, the machine can handle continuous flow production without bottlenecks. Bottles, boxes, or other items are accurately picked, aligned, and inserted into cartons or containers at a speed far exceeding manual labor capabilities. For manufacturers, this translates into significantly higher throughput while maintaining consistent packaging quality. In practice, production lines using the automatic packer have observed up to a 40% increase in daily output compared to semi-automatic packing solutions.

Compatibility with Different Packaging Sizes

Flexibility is crucial for modern production environments, where manufacturers often need to handle diverse product formats. The automatic packer is engineered to accommodate a wide range of packaging sizes and configurations. Adjustable guides, modular conveyors, and adaptable gripping mechanisms allow the system to switch between different product dimensions quickly and efficiently. This versatility reduces downtime during product changeovers and minimizes the need for multiple packing machines. As a result, manufacturers can respond more effectively to market demands and seasonal product variations.

Stable and Reliable Operation

Operational stability is a critical factor for achieving both efficiency and accuracy. The automatic packer is built with high-quality components, including industrial-grade motors, reinforced frames, and precision-controlled actuators. These design features ensure minimal vibration and consistent operation under continuous load. A stable machine reduces packaging errors, prevents product damage, and lowers maintenance requirements. For project managers, this reliability translates into predictable production cycles, fewer interruptions, and reduced overall operational costs.

Enhanced Accuracy and Quality Control

The automatic packer maintains high accuracy through its intelligent control system, which precisely regulates movement, alignment, and timing. Items are consistently positioned in the correct orientation, and the machine ensures that each package is filled and sealed according to specifications. By reducing human error, the automatic packer helps maintain product quality, minimizes waste, and enhances brand reputation. Industry studies suggest that automated packing systems can reduce packaging defects by more than 25%, a critical metric for manufacturers seeking to meet stringent quality standards.

Integration with Existing Production Lines

Another advantage of the automatic packer is its ability to integrate seamlessly with existing production line equipment. Whether it is upstream conveyors, labeling machines, or downstream carton sealing equipment, the automatic packer can synchronize with various production stages, ensuring smooth material flow and consistent cycle times. This integration reduces manual handling, streamlines operations, and enables manufacturers to achieve end-to-end automation.

Optimization Methods

While the automatic packer offers substantial inherent benefits, project managers can implement specific optimization methods to maximize its performance.

Conveyor and Line Synchronization

Ensuring proper synchronization between the automatic packer and upstream/downstream equipment is critical. By aligning conveyor speeds and timing with the packer's cycles, manufacturers can minimize bottlenecks and prevent accumulation of products at packing stations. Regular monitoring and adjustment of conveyor alignment contribute to smoother operations and higher throughput.

Adaptive Product Changeover

Frequent product changeovers are common in diverse production environments. The automatic packer supports quick adjustments for different packaging sizes, but optimization requires predefined settings for each product type. By maintaining a digital product database with stored parameters for each item, operators can switch between products rapidly without compromising accuracy. This method significantly reduces downtime and improves overall production line flexibility.

Preventive Maintenance and Monitoring

To maintain peak efficiency, preventive maintenance programs are essential. Key components of the automatic packer, including motors, sensors, and actuators, should be inspected and serviced according to a fixed schedule. Monitoring performance metrics such as cycle time, error rates, and equipment vibration helps identify potential issues before they escalate. Implementing predictive maintenance reduces unplanned downtime and prolongs equipment life.

Operator Training and Best Practices

Even with automated systems, well-trained operators are essential. Providing training on proper setup, troubleshooting, and parameter adjustments ensures that the automatic packer performs optimally. Operators familiar with the machine’s capabilities can identify small inefficiencies, make timely adjustments, and maintain consistent packaging quality.

Performance Analysis and Results

The implementation of the automatic packer has shown measurable improvements in production line performance. High-speed automated packing has increased throughput by an average of 35–40%, reducing the need for additional labor during peak periods. Accuracy improvements have led to a significant decrease in packaging defects, minimizing product waste and associated costs.

Manufacturers utilizing the automatic packer have also benefited from reduced changeover times and enhanced line flexibility, allowing them to adapt quickly to market demand fluctuations. Stable operation and integrated monitoring systems ensure continuous productivity and predictable cycle times, which are critical for large-scale production planning.

Furthermore, the equipment’s compatibility with various packaging sizes has eliminated the need for multiple packing stations, optimizing factory floor space and lowering capital expenditure. By combining speed, precision, and reliability, the automatic packer provides both immediate efficiency gains and long-term value, proving its role as a strategic asset for modern manufacturing operations.

In conclusion, the automatic packer from Tianjin ENAK delivers a comprehensive solution for manufacturers seeking to enhance packaging speed and accuracy. Its high-speed automated operation, versatile compatibility, and stable performance, when combined with proper optimization and maintenance practices, enable production lines to achieve measurable improvements in efficiency, quality, and cost-effectiveness.