Description

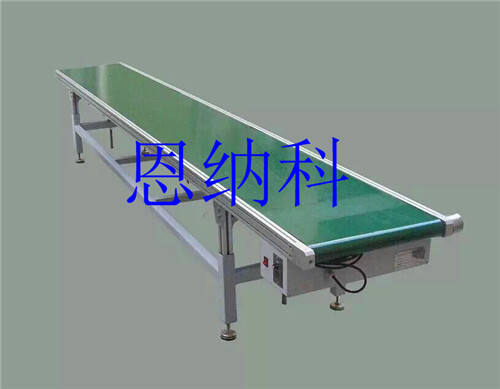

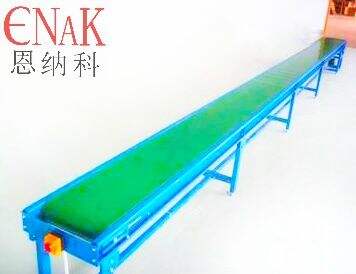

ENAK (Tianjin) Automation Equipment Co., Ltd presents the ENKS-03 Belt Conveyor, specially designed for the food industry’s production and packaging lines. This conveyor system facilitates efficient and precise handling of packaging materials and supplies, ensuring smooth operation and high throughput in food processing environments.

Product Overview

The ENKS-03 is a belt conveyor solution optimized for transporting food packaging supplies such as bottles, cartons, bags, and other containers. Constructed with food-grade materials, it ensures hygienic and contamination-free transportation suitable for strict industry standards.

High Performance

Featuring stable and consistent belt drive mechanisms, the system provides reliable movement with minimal vibration, reducing product damage and maintaining packaging integrity.

Precise Handling

Advanced synchronous belt and variable-speed chains enable accurate positioning and accumulation of goods, supporting assembly line operations.

Flexible Pathing

Combining straight, curved, inclined, and declined sections, the conveyor adapts to complex production layouts, allowing multi-directional product flow.

Modular Construction

The system is built from standardized modules that allow easy expansion, reconfiguration, or relocation to meet evolving production demands.

User-Friendly Interface

Equipped with intuitive control units for speed regulation, emergency stop and status monitoring, simplifying operation and maintenance tasks.

| Parameter | Value |

| Model | ENKS - 03 |

| Minimum Order Quantity | 1 meter |

| Price Step (USD) | 599 |

| Overall Dimensions | Customizable |

| Outer Packaging Dimensions | 1203X235X265 cm |

| Gross Weight (KG) | 500 |

| Shipment Quantity | 1 |

| Estimated Shipment Time | 35 |

| Packaging Method | Wooden Case |

| Service | Free Replacement of Parts |

| Power | 7.5 KW |

| Load Capacity | Customizable |

| Conveyor Width | 20 - 2000mm, Customizable |

| Material | Stainless Steel |

| Speed | Adjustable, 8 - 12 M/min |

| Maximum Weight of Goods | Customizable |

| Applicable Products | Cartons, Pallet - boxes, Plastic Baskets, Bags, Large Barrels, Packaging Boxes |

| After - sales Service System | One - to - one Video Remote Guidance |

Product Advantages

The ENKS-03 Belt Conveyor delivers multiple advantages tailored to the rigorous demands of food industry production lines:

Precise Positioning and Accumulation

Utilizing precision-controlled synchronous belts and zero-backlash dual-speed chains, the ENKS-03 achieves exact product placement, pause, and accumulation on the line. This accuracy is vital in packaging and assembly operations where timing and alignment influence overall quality and efficiency. The conveyor handles delicate products gently while maintaining strict position control to prevent misfeeds or jams.

Multi-Directional Transport Capability

The system supports multi-directional flow by integrating various conveyor segments such as straight runs, 90-degree curves, lifts, and declines. This flexibility enables routing products vertically and horizontally, optimizing factory floor space usage and facilitating complex production process flows. Such configuration adaptability reduces the need for manual handling and multiple transfers.

Modular Design for Scalability and Flexibility

Built from standardized modular components, the ENKS-03 is highly adaptable to layout changes. New modules can be added or reconfigured easily, supporting production capacity growth or line alterations without major downtime or capital expenses. This modularity future-proofs the production investment by enabling customized designs and quick upgrades.

Durability and Hygiene Compliance

Constructed using food-grade stainless steel frames and FDA-compliant belts, the conveyor meets stringent industry hygiene standards. Smooth surface finishes and easily cleanable components reduce contamination risk and simplify sanitation protocols essential for food safety.

Energy Efficient Operation

Optimized motor drives and controlled belt speeds minimize energy consumption while maintaining consistent product flow. Variable speed options allow energy usage to sync precisely with production demand.

Easy Maintenance and Operation

Tool-free belt adjustments, modular replacement parts, and accessible design facilitate swift maintenance, reducing unplanned downtime. An intuitive control panel provides operators with real-time status and operational parameters for efficient supervision.

Integration Compatibility

The ENKS-03 is designed to interface seamlessly with other packaging machines such as fillers, labelers, and case packers, enabling cohesive production line automation.

Operation Guide

To ensure optimal performance and safety of the ENKS-03 Belt Conveyor, follow these key operational steps:

Startup Procedures

Turn on the power supply and verify that emergency stops are disengaged. Inspect the belt and rollers for smoothness and confirm no obstructions are present on the conveyor path.

Adjustments and Settings

Set the conveyor speed using the control panel, matching production line rhythm. Adjust belt tension and alignment as necessary using manual adjustment points to ensure flat and taut belt surface.

Load and Unload Procedures

Place products carefully onto the conveyor at the designated loading zone. Ensure the unloading mechanism is properly aligned to prevent blockages or product jams.

System Monitoring

Continuously monitor speed, vibration levels, and emergency stop indicators. Respond promptly to alarms or irregularities to avoid downtime or damage.

Scheduled Maintenance

Clean belts and frames regularly according to the cleaning protocols to meet food hygiene regulations. Lubricate moving parts using recommended food-grade lubricants.

Shutdown Guidelines

Power down the system following prescribed procedures. Clear residual products and clean the conveyor surface before turning off.

FAQ

Q1: What types of products can the ENKS-03 conveyor handle?

A: It can transport various food packaging supplies including bottles, cartons, pouches, and containers.

Q2: Can the conveyor speed be adjusted?

A: Yes, speeds are adjustable via the control panel manually or integrated with upstream/downstream equipment.

Q3: Is the system adaptable to complex plant layouts?

A: The modular design allows configuration in straight, curved, inclined, and declined sections enabling complex routing.

Q4: How does the conveyor ensure food safety?

A: Built with FDA-compliant materials and designed for easy cleaning to meet stringent hygiene standards.

Q5: What maintenance is required?

A: Routine cleaning, lubrication, and inspection of belts and rollers ensure prolonged efficient performance.

We invite you to contact ENAK (Tianjin) Automation Equipment Co., Ltd to discover how the ENKS-03 Belt Conveyor can enhance your food industry production line. Our professional team will provide customized layout design, installation support, and after-sales service.

Please click the “Inquiry” button below or contact us directly to submit your specific production requirements. We will quickly respond with expert consultations, competitive quotes, and technical assistance to help upgrade your packaging process with reliable and efficient conveyor solutions.