Description

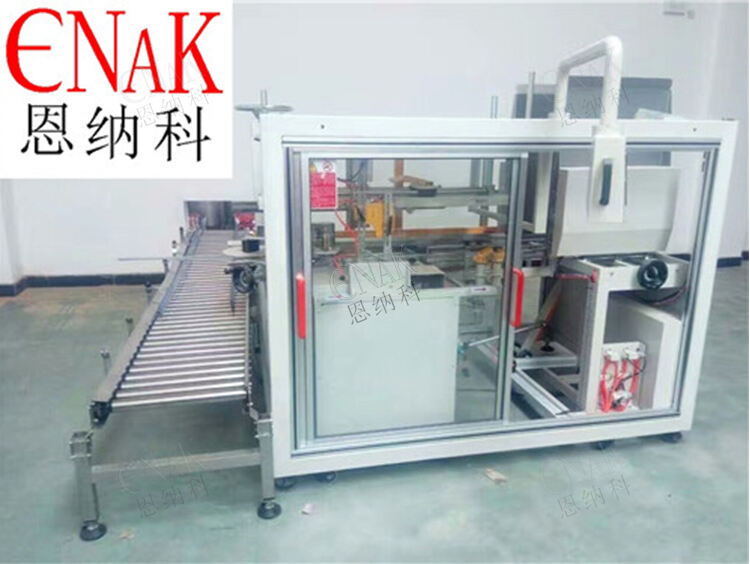

The Automatic High-Speed Case Opening Erecting Machine For Packaging Line (Model ENKK-02) is a state-of-the-art carton erector developed by ENAK (Tianjin) Automation Equipment Co., Ltd. Designed for high-speed packaging lines, this machine automates carton opening, forming, and bottom sealing with exceptional precision and reliability.

High-Quality Components: Equipped with imported electrical and pneumatic parts, the carton erector ensures stable performance.

Proprietary Technology: Developed with years of experience and integrating Japanese and German technologies, this carton erector achieves top-level reliability.

Superior Quality: Every component undergoes aging tests to guarantee long-term stability.

User-Friendly Operation: With horizontal carton storage, empty cartons can be replenished at any time without stopping the line. Adjusting carton sizes requires only manual settings, making it flexible and easy to use.

Full Automation: The machine automatically opens cartons, folds flaps, and seals bottoms with PLC + HMI control.

Safety Features: Automatic stop when the door opens, air cut-off protection, and precision cam drive ensure safe operation.

Efficient Design: Equipped with a cam continuous system and frequency converter for adjustable speed, the carton erector operates smoothly without vibration.

With high precision, safety, and efficiency, the ENKK-02 carton erector is an indispensable part of modern packaging lines.

Product Advantages

1. High-Speed Performance

The ENKK-02 carton erector offers rapid carton forming and bottom sealing. Capable of handling continuous production lines, it boosts efficiency and reduces downtime.

2. Reliable Imported Parts

Built with premium electrical and pneumatic components, the carton erector ensures durability, precision, and long-lasting performance, minimizing maintenance requirements.

3. Advanced Automation

The integration of PLC programmable control and an HMI touch screen makes this carton erector simple to operate while providing full automation for carton opening, flap folding, and bottom sealing.

4. Flexible for Multiple Carton Sizes

Operators can easily switch between carton dimensions with manual adjustments. This flexibility enables manufacturers to handle diverse packaging needs without frequent stoppages.

5. Cost and Labor Savings

By replacing manual carton erecting and bottom sealing, the carton erector reduces labor costs, eliminates human error, and ensures uniform packaging quality.

6. Enhanced Safety

Safety mechanisms such as automatic stop upon door opening and air supply cut-off protect workers while maintaining production stability.

7. Precision and Durability

The carton erector adopts a cam-driven continuous system, ensuring precise operation and reduced vibration. Combined with robust construction, it guarantees long-term reliability.

8. Energy-Efficient Operation

The use of a frequency converter allows adjustable speeds based on production needs, saving energy while maximizing throughput.

This carton erector not only streamlines production but also enhances packaging consistency, safety, and cost efficiency.

Application Scenarios

The ENKK-02 carton erector is versatile and suitable for various industries:

Food and Beverage: For cartons of biscuits, instant noodles, bottled water, soft drinks, and juices.

Household and Daily Chemicals: Perfect for detergents, shampoos, and cleaning products packed in cartons.

Pharmaceuticals and Healthcare: For medicines, supplements, and nutrition products requiring safe and neat carton packaging.

Electronics and Industrial Goods: For electronic components, appliances, tools, and chemical products.

E-commerce and Logistics: Supports large-scale order fulfillment with fast and consistent carton opening and sealing.

The carton erector ENKK-02 provides efficiency and flexibility across industries, making it an essential asset for automated packaging lines.

Frequently Asked Questions

Q1: What carton sizes can the carton erector handle?

A1: It can handle multiple carton dimensions with quick manual adjustments.

Q2: How many workers can one carton erector replace?

A2: One carton erector can replace 3–5 workers, reducing labor costs significantly.

Q3: Is the machine difficult to operate?

A3: No, the PLC touch-screen interface makes it very easy and intuitive.

Q4: Can the carton erector be customized?

A4: Yes, customization is available to match carton specifications and production line requirements.

Q5: How is daily maintenance handled?

A5: Simple checks of pneumatic parts, belts, and electrical components are sufficient.

If you are seeking a reliable, efficient, and safe carton erector, the Automatic High-Speed Case Opening Erecting Machine For Packaging Line (ENKK-02) from ENAK (Tianjin) Automation Equipment Co., Ltd. is your best choice.

Contact us today with your packaging needs and contact details, and we will provide you with a tailored solution and competitive quotation!