Description

Product Overview:

The Automatic Labeler Machine from Tianjin ENAK is a high-performance labeling solution designed with advanced international components. It is tailored for industries such as food, beverage, daily chemicals, and pharmaceuticals, delivering high-speed, precise, and stable labeling performance. The machine adopts an intelligent control system combined with a reliable transmission design, ensuring smooth operation and accurate labeling results.

Core Performance:

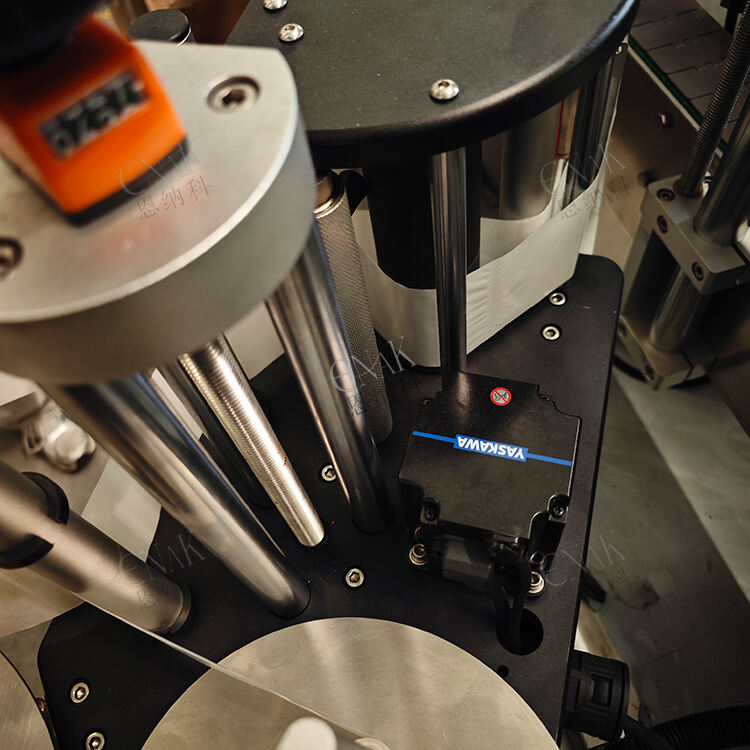

The main unit is equipped with a 750W Yaskawa ultra-low inertia servo motor and a Yaskawa servo amplifier from Japan, offering fast response and precise positioning. Together with a Danfoss inverter, Taiwan AC motors, and a Siemens PLC, the Automatic Labeler Machine ensures reliable operation and intelligent control. The Weinview color HMI supports both Chinese and English, providing a user-friendly, intuitive interface.

The mechanical structure includes an efficient conveyor system, bottle separating and aligning mechanisms, stainless-steel guiding rails, and versatile pressing and wiping components, enabling the Automatic Labeler Machine to adapt to different bottles and labels while maintaining stable performance.

Stability and Reliability:

Equipped with Leuze label sensors and Leuze photoelectric detection systems from Germany, the Automatic Labeler Machine monitors label and product status in real-time, avoiding errors such as missing labels or misalignment.

Item |

Specification |

Operation Mode |

Human-Machine Interface (HMI) |

Labeling Speed |

50 m/min |

Labeling Accuracy |

±1 mm |

Motor Power Supply |

Single-phase three-wire, AC 220V / 50Hz, 3KW |

Control Voltage |

DC 24V |

Max. Label Roll Diameter |

330 mm |

Max. Label Width/Height |

190 mm |

Core Diameter |

76.2 mm |

Machine Dimensions |

(L)3040 mm × (W)1920 mm × (H)1830 mm |

Environmental Conditions |

Altitude: 3–2000 mTemperature: 0℃–40℃Humidity: 40%–95% |

Machine Weight |

300 KG |

Conveyor Height |

900 ± 50 mm |

Conveyor Width |

82.6 mm |

Product Advantages

Food-grade Stainless Steel and Aluminum Structure

The Automatic Labeler Machine is constructed from food-grade 304 stainless steel and aluminum alloy with electrophoresis and oxidation treatment. This ensures corrosion resistance, durability, and compliance with food and pharmaceutical industry standards. The modular design makes adjustments and component replacements fast and convenient, reducing downtime and maintenance costs.

Smart Parameter Storage and Recall

The machine can store up to 10 sets of labeling parameters for different products. For production lines requiring frequent bottle and label changes, operators only need to recall stored data to switch settings quickly. This feature significantly enhances efficiency and production flexibility.

Wide Application Range

The Automatic Labeler Machine is particularly suitable for labeling square bottles with high precision. It accommodates bottles used in beverages, condiments, and household products, while also supporting labels of various materials, including paper, film, and transparent labels. This versatility makes it a valuable asset across multiple industries.

Easy Operation and Learning Curve

The user interface is simple and intuitive, with Chinese and English language support. Even first-time operators can quickly learn the system, avoiding delays caused by insufficient training. Routine maintenance is straightforward, requiring no specialized personnel.

Adaptability to Tapered Bottles

The Automatic Labeler Machine is designed to handle tapered bottles with ease. By replacing only a few parts, the system can achieve accurate labeling without deviation, preventing material waste and improving efficiency.

Eight-Dimensional Adjustable Labeling Head

The unique eight-dimensional adjustment mechanism allows the labeling head to be quickly repositioned to match different bottle shapes. For tapered or irregular bottles, operators can make manual adjustments without tools or screws, achieving precise alignment with minimal effort. This not only improves accuracy but also reduces operator workload.

In conclusion, the Automatic Labeler Machine offers a combination of precision, reliability, flexibility, and user-friendliness, making it the ideal choice for modern production lines aiming to boost capacity and product quality.

Application Scenarios

The Automatic Labeler Machine is widely applicable across production lines in food, beverage, pharmaceutical, and personal care industries:

Food Industry: For bottles containing sauces, condiments, and beverages, the Automatic Labeler Machine ensures fast and accurate labeling, improving production efficiency.

Pharmaceuticals and Health Products: Suitable for both square and tapered bottles, the Automatic Labeler Machine guarantees bubble-free and precise labeling, meeting high industry standards.

Daily Chemical Industry: For personal care items such as shampoos, body wash, and cleaning products, the Automatic Labeler Machine provides reliable performance even with irregular-shaped bottles.

Beverage Industry: From water bottles to functional drinks, the Automatic Labeler Machine supports continuous high-speed operations, ensuring product consistency and brand visibility.

Whether for large-scale mass production or frequent product variations, the Automatic Labeler Machine helps companies increase efficiency, reduce costs, and maintain labeling quality.

FAQ

Q1: Can the Automatic Labeler Machine work with transparent labels?

A1: Yes, it is equipped with a highly sensitive photoelectric detection system that accurately identifies transparent labels.

Q2: Is complicated adjustment required when changing bottles?

A2: No. The Automatic Labeler Machine can store 10 parameter sets. Simply recall the relevant data to complete the switch instantly.

Q3: Can it handle irregular or tapered bottles?

A3: Yes. Thanks to the eight-dimensional adjustable labeling head, the Automatic Labeler Machine can easily adapt to tapered or irregular shapes.

Q4: Do operators need specialized training?

A4: No. The interface is intuitive with bilingual support, making it easy to learn and operate.

Want to learn more about the Automatic Labeler Machine or receive a customized solution?

Please leave your inquiry information today, and our professional team will contact you promptly with detailed specifications and quotation support.