Automatic Canning Depalletizer Glass Bottles Palletizer Filled Tin Cans Depalletizer Machine ENKM-02-X

Description

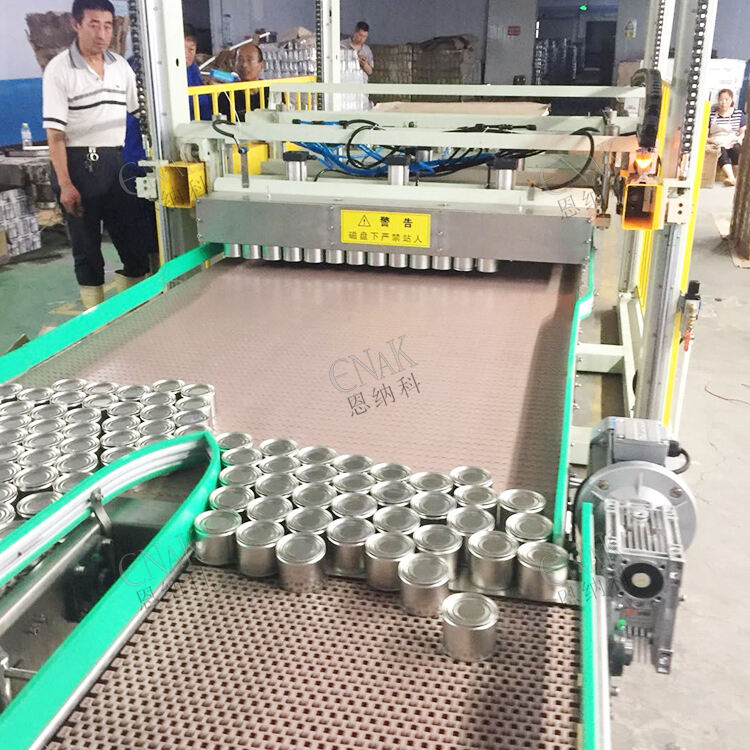

ENAK (Tianjin) Automation Equipment Co., Ltd. proudly presents the ENKM-02-X Automatic Canning Depalletizer / Glass Bottles Palletizer / Filled Tin Cans Depalletizer Machine, a high-performance Palletizer System integrating depalletizing, palletizing, and pallet handling. Designed for modern beverage, food, and canning production lines, it delivers efficiency, precision, and reliability.

Product Overview:

This system handles glass bottles, filled tin cans, canned beverages, and various boxed products for automated depalletizing and palletizing. Its compact structure allows flexible integration with existing conveyor and packaging lines, supporting continuous high-speed production.

High Performance:

Equipped with high-speed servo drives and intelligent control, the system executes precise, continuous depalletizing and palletizing. A single unit can process multiple pallets per hour, significantly improving production line efficiency while reducing manual labor.

Automation Advantages:

Advanced vision detection, mechanical alignment, and multi-point sensing ensure high picking and placement accuracy. The system stacks products neatly and stably, with adjustable stacking patterns and pallet sizes to accommodate diverse packaging specifications.

Intelligent Control & Monitoring:

Integrated PLC control and touchscreen interface allow easy operation and real-time monitoring of product status, pallet position, and anomalies, ensuring continuous, safe production.

Reliability Design:

Core components are sourced from top international brands. The system is stable and reliable, suitable for 24/7 continuous operation, providing long-term automated pallet handling solutions.

The ENKM-02-X Palletizer System not only delivers efficient, precise, and stable depalletizing and palletizing but also optimizes factory layout and reduces labor costs, making it an ideal solution for modern automated production lines.

| Parameter | Value |

| Model | ENKM-02-X |

| Minimum Order Quantity | 1 |

| Price Step (USD) | 25000 |

| Unit | Set |

| Overall Dimensions | 1203X235X265 |

| Outer Packaging Dimensions (cm) | 1203X235X265 |

| Gross Weight (KG) | 2500 |

| Shipment Quantity | 1 |

| Estimated Shipment Time | 45 |

| Packaging Method | Wooden Case |

| Service | Free Replacement of Parts |

| Power | 7KW |

| Voltage | 380V/50HZ |

| Body Material | Carbon Steel Baked Enamel |

| Load (KG) | 300 |

| Working Radius | 1750 |

| Palletizing Speed | 0 - 2 layers/min |

| Applicable Product Types | Tin - plate Canned Goods, Glass - bottle Canned Goods (with Iron Lids) |

| Pallet Size (MM) | L800-1300*W800-1200*H100-150 |

| Pallet Supply Method | Manual Placement/Automatic Placement |

| Warranty Period | 3 Years |

| After - sales Service System | Video Technical Support, On - site Guidance, On - site Installation, Commissioning and Training, Online Support, Free Spare Parts |

| Core Components | Motor, Pump, PLC, Engine, Gear, Bearing, Pressure Vessel |

Product Advantages

Significant Cost Reduction

The ENKM-02-X Palletizer System can replace 4-6 workers performing repetitive handling and stacking tasks. Long-term operation significantly reduces labor, management, and social security costs. Robotic automation minimizes human intervention, increases line efficiency, and prevents errors or accidents, saving on management and training costs.

Energy Saving and Environmentally Friendly

The system features advanced energy regeneration technology, converting kinetic energy into electricity during deceleration, lowering, and stopping, reducing overall energy consumption. Compared to traditional equipment, the ENKM-02-X Palletizer System saves considerable electricity, promoting sustainable green production. It also operates quietly, meeting modern factory environmental standards.

Multiple Safety Protections

Equipped with robust safety fences, light curtains, emergency stop buttons, and collision sensors, combined with software interlocks, the system ensures absolute human-machine safety. Even during high-speed continuous operation, operators and production lines are fully protected. The system supports self-diagnosis and alarm notifications, further enhancing operational safety.

This Palletizer System offers a highly efficient, safe, and sustainable automated pallet handling solution, reducing labor costs and energy consumption while ensuring safe operation.

Production Process

Pallet Feeding:

Full pallets are automatically transported to the depalletizing area via conveyors. Sensors detect pallet position in real-time to ensure smooth, continuous feeding with minimal human intervention.

Depalletizing Operation:

Robots or mechanical arms pick each item using vision positioning or mechanical alignment, removing layers carefully to avoid bottle or can collisions or tipping.

Palletizing Operation:

Picked products are stacked on target pallets according to preset stacking patterns and pallet dimensions. Each layer adjusts spacing and orientation automatically to achieve stable and neat pallet stacks.

Dynamic Monitoring:

Sensors and PLCs continuously monitor product, pallet, and robot status. Any anomaly, such as product misalignment, missing pallets, or mechanical errors, triggers an alarm and stops the system, ensuring safe operation.

Packaging Output:

Completed pallets are conveyed to downstream packaging or logistics areas, enabling full-process automation, reducing manual handling, and improving line efficiency.

Quality Control:

Optional vision inspection modules check product placement and detect defects, ensuring pallet stability and product quality while minimizing rework and waste.

Through this automated production process, the ENKM-02-X Palletizer System delivers efficient, safe, and precise depalletizing and palletizing, providing a comprehensive solution for modern industrial production lines.

FAQ

Q: What products can the ENKM-02-X Palletizer System handle?

A: Suitable for glass bottles, filled tin cans, and other boxed or bottled products, ideal for beverage, food, and personal care industries.

Q: Can it reduce labor costs?

A: Yes, it replaces 4-6 workers in repetitive tasks, significantly lowering labor and management expenses long-term.

Q: Is the system energy-efficient and environmentally friendly?

A: Yes, energy regeneration technology feeds kinetic energy back to the grid, reducing overall energy consumption.

Q: Is it safe to operate?

A: Yes, equipped with safety fences, light curtains, emergency stops, collision sensors, and software interlocks, ensuring safe human-machine interaction.

Leave your contact information to receive detailed pricing and customized solutions for the ENKM-02-X Automatic Canning Depalletizer / Glass Bottles Palletizer / Filled Tin Cans Depalletizer Machine, enabling efficient, safe, and eco-friendly automated pallet handling.