Description

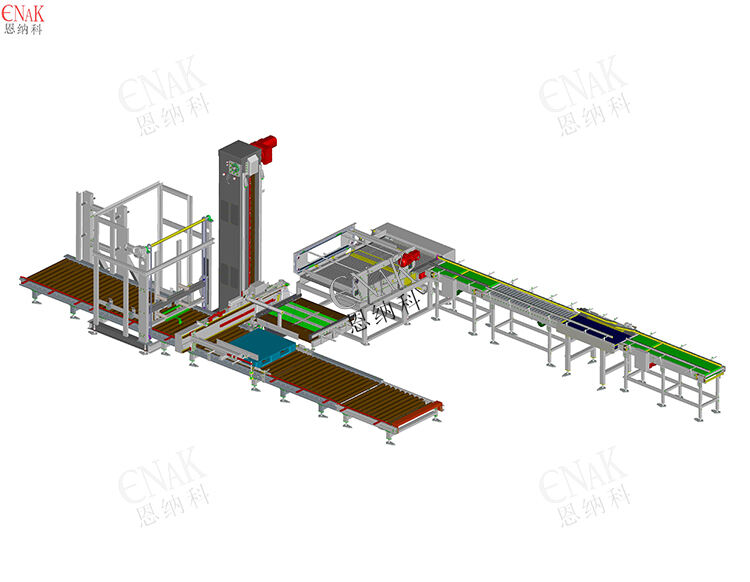

ENAK (Tianjin) Automation Equipment Co., Ltd. proudly presents the ENK-MD1800E-100 Automated Single Column Case Palletizer System, a cutting-edge solution designed for modern high-efficiency production lines. This Palletizer System integrates advanced automation control to achieve fully automated stacking of various products and packaging specifications.

Product Overview:

The ENK-MD1800E-100 Palletizer System is ideal for single-column palletizing of bottled, canned, and boxed products. It supports multiple pallet sizes and stacking patterns while maintaining a compact footprint, enabling seamless integration into existing production lines.

High Performance:

Equipped with high-precision servo drives and an intelligent control system, this Palletizer System performs high-speed, accurate automated stacking. It can handle hundreds of cases per hour, significantly boosting production efficiency.

Automation Advantages:

The system allows operators to switch stacking programs directly on the touchscreen, adapting to different products and box types without changing mechanical components. This ensures continuous production with minimal manual intervention.

Reliability Design:

Core components, including servo motors, robotic arms, and the PLC controller, are sourced from top international brands. The system delivers high stability, suitable for 24/7 continuous operation, providing a long-term reliable automated palletizing solution.

The ENK-MD1800E-100 Palletizer System offers an intelligent, efficient, and dependable approach to modern industrial palletizing.

| Parameter | Value |

| Model | ENK - MD1800E - 100 |

| Minimum Order Quantity | 1 |

| Unit | Set |

| Overall Dimensions | H: 3200MM |

| Packaging Method | Wooden Case |

| Service | Free Replacement of Parts |

| Power | 6KW |

| Voltage | 380V/50HZ |

| Body Material | Carbon Steel Baked Enamel |

| Load (KG) | 100 |

| Working Radius | 1830 |

| Palletizing Height | 1800 |

| Palletizing Speed | 6 - 8 times/min |

| Applicable Product Types | Carton - type, Film - package type, Woven - bag type, Large - barrel type |

| Pallet Size (MM) | L800-1200*W800-1200*H100-150 |

| Gripping Method | Suction Cup, Clamping Plate |

| Pallet Supply Method | Manual Placement/Automatic Placement |

| Warranty Period | 1 Year |

| After - sales Service System | Video Technical Support, On - site Guidance, On - site Installation, Commissioning and Training, Online Support, Free Spare Parts |

Product Advantages

Powerful Flexibility

The ENK-MD1800E-100 Palletizer System offers exceptional operational flexibility. Operators can simply switch programs on the touchscreen to quickly adapt to different products, box types, packaging specifications, and stacking patterns without changing any mechanical components. Whether handling bottled beverages, canned foods, or cartons, the system ensures efficient palletizing while minimizing setup time and reducing manual intervention. This flexibility allows production lines to switch between different SKUs rapidly, enhancing overall operational agility.

Modular Design

The Palletizer System features a modular architecture, allowing customers to configure modules such as pallet handling, robotic arms, and conveyors according to their current production capacity and budget. The system is future-proof, enabling upgrades such as additional grippers, vision inspection modules, or extra pallet handling units. Modular design not only safeguards investment but also simplifies maintenance and troubleshooting, ensuring continuous and reliable production.

Space-Saving Design

The ENK-MD1800E-100 Palletizer System has a compact structure, occupying minimal floor space, and can easily be integrated into existing production lines. Its space-efficient design optimizes factory layouts, improving workflow and material handling efficiency. Compared with traditional large-scale palletizers, this system delivers high-speed, precise stacking within a limited footprint, making it ideal for factories with constrained space or tight production layouts.

By combining powerful flexibility, modular design, and space-saving structure, the ENK-MD1800E-100 Palletizer System provides an automated palletizing solution that enhances production efficiency, operational flexibility, and workspace utilization.

Operation Guide

Startup Preparation:

Verify power and air supply connections, ensure all components are unobstructed, and turn on the main power and control panel.

Program Selection:

Use the touchscreen to select preset stacking programs. The system can quickly switch between different products, box types, and stacking patterns.

Operational Procedure:

Start the conveyor and palletizing robot. The system automatically picks up items, stacks them on the pallet, and arranges them according to the programmed pattern. Operators can monitor production status in real-time and adjust stacking speed and layer height as needed.

Error Handling:

The system features fault detection and alarm functions. In case of product misalignment, missing pallets, or mechanical anomalies, it automatically stops and alerts operators.

Maintenance:

Regularly clean the equipment, inspect the drive system and grippers, and perform routine checks to maintain stable operation and prolong system life.

The ENK-MD1800E-100 Palletizer System is user-friendly, intelligently controlled, and significantly reduces manual labor while increasing production line automation.

FAQ

Q: What products can the ENK-MD1800E-100 Palletizer System handle?

A: Suitable for single-column palletizing of bottled, canned, and boxed products, especially in beverage, food, and personal care industries.

Q: Is switching between different box types or sizes difficult?

A: No, the system allows rapid program changes on the touchscreen without replacing mechanical components, making operation simple and convenient.

Q: Does the system occupy a lot of floor space?

A: No, the compact design saves space and can be easily integrated into existing production lines, optimizing factory layout.

Q: Can the system be upgraded in the future?

A: Yes, the modular design supports adding grippers, vision systems, and other modules, protecting investment and extending the system’s lifecycle.

Leave your contact information to receive a professional quotation and customized solution for the ENK-MD1800E-100 Automated Single Column Case Palletizer System. Our team will help optimize your production line with high-speed, precise, and space-efficient automated palletizing.