Description

General Description

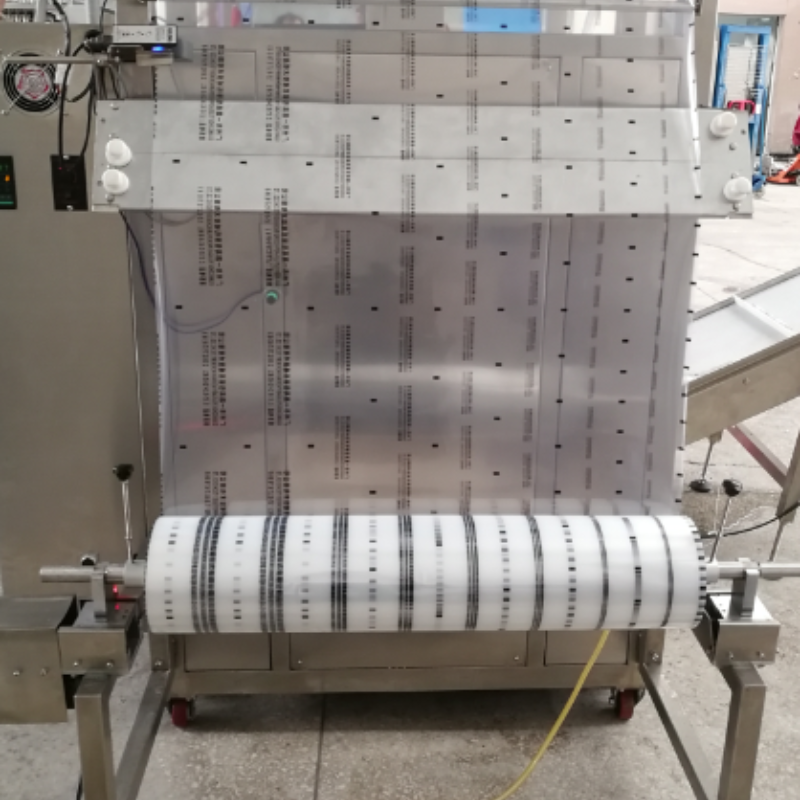

The Sachet Tomato/Ketchup Line is a fully automated production solution designed for tomato sauce, ketchup sachets, and tomato-based condiments. It covers the entire process from raw material preparation, sterilization, precise filling, sealing, to finished packaging, ensuring fast, efficient, and standardized production.

Performance Features

High-Precision Filling: Uses advanced servo-driven or piston dosing systems to guarantee accurate filling for each sachet.

Flexible Specifications: Supports multiple sachet sizes such as 20g–50g. With simple part replacements, quick changeovers can be completed to adapt to different production requirements.

Stable Operation: Controlled by PLC intelligent systems, ensuring automated operation, real-time monitoring, and stable productivity.

Food Safety Assurance: Optional UHT sterilization and aseptic filling systems significantly extend shelf life while maintaining product quality.

The Sachet Tomato/Ketchup Line is widely used in food processing plants, condiment factories, and catering supply chains, helping businesses achieve high-efficiency production that meets international standards.

|

|

|

Product Advantages

Excellent Productivity and Flexibility

High-Speed Output: With servo control and optimized pipeline design, the line achieves hundreds to thousands of sachets per minute.

Quick Changeover: Modular design enables rapid switching between sachet sizes, reducing downtime.

Continuous Operation: Fully automated from formulation to packaging, ensuring consistent productivity.

Outstanding Product Quality and Safety

Sterile or High-Temperature Filling: Equipped with UHT sterilization and aseptic filling, extending shelf life without excess preservatives.

Accurate Dosing: Advanced servo or piston systems guarantee precise net weight per sachet, reducing waste.

International Standards: All contact parts use 304/316 stainless steel, meeting GMP and HACCP standards, easy to clean and maintain.

Significant Operational Cost Control

Labor Savings: Requires only minimal operators, cutting workforce costs compared to semi-automated lines.

Reduced Material Loss: Precise filling minimizes overfill; stable film tension lowers leakage and defective rates.

Energy Optimization: Intelligent temperature control and heat recovery modules reduce consumption of water, electricity, and steam.

|

|

Company Advantages

ENAK (Tianjin) Automation Equipment Co., Ltd., founded in 2012, is a specialized high-tech enterprise focusing on turnkey solutions for ready meal production lines, canned food production lines, and back-end packaging lines. The company integrates R&D, design, manufacturing, sales, and after-sales service, with strong influence in the industry.

-

Product Portfolio: Includes deep learning inspection equipment (raw material sorting, foreign object detection, coding inspection), canned food processing machines (empty can depalletizer, bottle washer, peeler, splitting machine, filler, sterilizer, conveyors), and packaging equipment (labeling machines, case unpacker, case packer, case sealer, palletizer, depalletizer).

-

Turnkey Solutions: Offers one-stop services from single machines to complete factory design, with expertise in Sachet Tomato/Ketchup Line and Canned Tomato Paste Line.

-

Corporate Culture: With the philosophy of “bestowing grace and gathering talents; promoting disciplines to benefit the world,” ENAK is committed to advancing intelligent packaging equipment and enabling smart manufacturing for the food industry. Guided by values of “customer first, innovation, integrity, and joyful striving,” ENAK delivers high-quality services while building its global brand.

FAQ

Q1: What is the delivery time for a Sachet Tomato/Ketchup Line?

A1: A standard production line usually requires 3–4 months from design to delivery. Highly customized projects may take up to 6 months. Every line undergoes full testing before shipment to ensure fast installation and quick production startup.

Q2: What packaging sizes are supported?

A2: The Sachet Tomato/Ketchup Line is designed for 20g–50g sachets and can be adapted for other ranges upon request. Its modular design allows quick changeovers between different sachet formats, meeting diverse market demands.

Q3: How is after-sales service supported?

A3: ENAK provides a 12-month warranty, with 24/7 remote technical support and on-site service within 24–48 hours if needed. We also offer training, spare parts supply, and preventive maintenance programs to ensure long-term stability of the production line.

If you are looking for a high-efficiency, flexible, and reliable Sachet Tomato/Ketchup Line or Canned Tomato Paste Line, ENAK is your trusted partner. We provide tailored solutions, professional technical support, and turnkey project services to help you optimize productivity, reduce costs, and achieve international food safety standards.