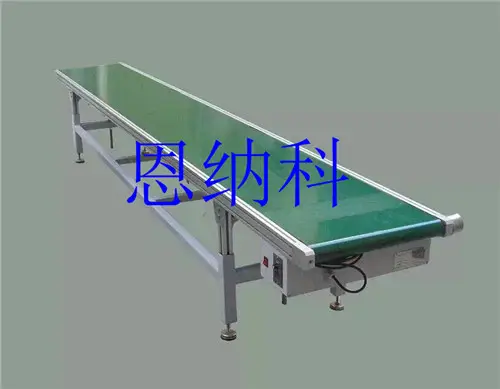

Tianjin ENAK, a leading Chinese manufacturer of high-quality belt conveyors, delivers production line solutions that drive sales and efficiency for global manufacturers. As a trusted production conveyor supplier in the manufacturing sector, ENAK's belt conveyor optimizes material handling with unbeatable heavy-load capacity, seamless integration, and superior efficiency at competitive prices.

Why Choose ENAK Belt Conveyors for Manufacturing Success

In modern manufacturing, material handling defines productivity, especially in high-throughput lines for packaging, filling, and heavy transfers. The ENAK belt conveyor from this Chinese manufacturer forms the reliable backbone, ensuring steady throughput, balanced load distribution, and simple sensor integration points that boost sales through consistent output.

High-quality design in the ENAK belt conveyor cuts variability from manual methods, slashing defects and lifting overall equipment effectiveness. Manufacturers pursuing advanced automation rely on its data interfaces for speed, torque, load, and motor monitoring, plus modular setups for fast reconfiguration at affordable prices. Reinforced frames, robust idlers, and powerful drives handle peak loads without failure, making it ideal for demanding production environments.

Essential benefits for sales-driven manufacturers include:

- Shorter changeover times to match production rhythms and accelerate output.

- Energy-efficient operation that lowers costs while maintaining high performance.

- Scalable specs tailored to throughput needs, avoiding wasteful over-investment.

Chinese production expertise shines in the ENAK belt conveyor, delivering measurable labor savings, reliable flow, and easy links to packaging systems. Plants worldwide choose this high-quality option from ENAK to enhance manufacturing sales and competitiveness.

Key Pillars Powering ENAK Belt Conveyor Performance

Tianjin ENAK, renowned Chinese belt conveyor manufacturer, builds its high-quality product around heavy-load capacity, seamless line integration, and peak efficiency. Production teams validate these during procurement for proven results in manufacturing sales.

Heavy-load capacity defines the ENAK belt conveyor: a welded steel frame with reinforced supports and durable idler mounts pairs with abrasion-resistant belts for sustained heavy use. Planetary gearboxes and TEFC motors provide thermal headroom for startups, while smart idler designs prevent sag on pallets—perfect for high-volume manufacturers seeking reliable, low-price solutions.

Seamless interfacing makes the ENAK belt conveyor a production line essential. Adjustable guides, leveling pads, and quick sensor mounts simplify setup. Controls offer PLC signals for start/stop, zero-speed detection, and emergency stops, plus fieldbus for real-time data, syncing flawlessly with depalletizers and packagers to protect product flow and sales targets.

High conveying efficiency maximizes the ENAK belt conveyor value. Low-friction components, precise pulleys, and tensioners reduce energy waste and slip. VFD soft-starts and regenerative braking cut power spikes, while accessible maintenance drops repair times. Inline zones support robots, minimizing manual work for cost-conscious Chinese manufacturing leaders.

Value-added features elevate sales appeal:

- Dust/splash covers for tough factory conditions.

- Adaptable skirtboards for diverse products.

- Built-in safety guards meeting global standards.

As a top Chinese producer, ENAK's belt conveyor preserves throughput, trims expenses, and drives manufacturing growth at unbeatable prices.

Real-World Wins: ENAK Belt Conveyor in Action

ENAK belt conveyors excel across industries, turning transport into smart production assets with rigid mechanics and controls that shorten cycles and lift sales. High-quality builds from this Chinese manufacturer deliver uptime for packaging, assembly, and flexible operations.

|

Application |

Production Scenario |

Sales-Boosting Results from ENAK Belt Conveyor |

|

Beverage Line |

24/7 filling infeed |

60% fewer interventions; encoder pulses prevent jams; peak output sustained without issues. |

|

Heavy Assembly |

Machining-to-station shuttles |

Motor monitoring predicts failures; cobot sync extends parts life; downtime drops sharply. |

|

Packaging Link |

Forming to vertical packing |

12% yield gain; guides ensure orientation; labor savings boost profitability. |

|

Multi-Product Plant |

Rapid SKU switches |

Quick clamps speed setups; tensioners improve startup quality; defects fall. |

Manufacturers report fewer touchpoints, better yields, and precise maintenance scheduling with the ENAK belt conveyor. Its scalability supports volume surges or product mixes, making it a sales powerhouse for Chinese-sourced high-quality gear.

Future-Proof Your Line with ENAK Belt Conveyor Innovations

ENAK anticipates trends like sensor upgrades, smart controls, and advanced materials, positioning its belt conveyor as a forward-thinking choice for manufacturers. Chinese production innovation creates digital line replicas for proactive fixes and efficiency gains.

Sensorization integrates load cells, vision systems, and health monitors into the ENAK belt conveyor, spotting wear early to safeguard sales uptime. Real-time insights transform maintenance from reactive to strategic.

Adaptive controls evolve the ENAK belt conveyor into a line partner. Machine learning refines speeds from motor data, easing operations and saving energy. Regenerative drives recover power, while modular add-ons like weighers speed changes—all at competitive prices.

Materials advances enhance the ENAK belt conveyor with tougher compounds, stable belts, and low-slip surfaces. Lightweight frames cut startup energy. Standardized links ensure easy integration, accelerating packaging deployments for global sales success.

Procurement leaders select ENAK belt conveyors for built-in smarts and adaptability, securing gains now and autonomous futures. As a high-quality Chinese manufacturer, ENAK offers the backbone for thriving production at prices that fuel sales.

Deploy ENAK Belt Conveyors: Practical Steps for Manufacturers

Integrate the ENAK belt conveyor seamlessly to unlock manufacturing potential:

- Evaluate Requirements: Analyze loads, speeds, and ties—match ENAK specs for optimal value.

- Customize Build: Choose pillars and options like fieldbus for your high-volume needs.

- Install and Verify: Use quick mounts to test PLC sync and flow.

- Track Performance: Leverage data for tweaks; modules handle product shifts.

- Expand Smartly: Add sensors and controls as sales grow.

With low total ownership costs, energy savings, and output boosts, the ENAK belt conveyor from Tianjin delivers ROI fast. Contact this Chinese manufacturer today for quotes, audits, and high-quality solutions that supercharge your production sales.