Case Overview

In today’s highly competitive beverage industry, production efficiency and hygiene compliance are critical metrics for operational success. Our company, a mid-sized beverage manufacturer, faced increasing demand for both volume and variety of products, from bottled water to flavored beverages. The need for reliable, high-throughput cleaning equipment became evident as our existing manual and semi-automatic systems struggled to maintain consistent quality and production pace. Bottles would occasionally be improperly cleaned, and manual handling created bottlenecks during peak production periods, resulting in increased labor costs and the risk of contamination.

To address these challenges, we explored automation solutions that could seamlessly integrate into our production line while providing consistent cleaning performance. After evaluating multiple options, we selected the Tianjin ENAK automatic bottle cleaner due to its reputation for efficiency, reliability, and adaptability to different bottle types. The equipment promised a combination of high-speed cleaning, automated bottle handling, and scalability across various production volumes.

From a project management perspective, the introduction of the automatic bottle cleaner marked a significant shift toward full production line automation. The system’s design allowed for automated infeed and outfeed of bottles, reducing manual labor, while its modular construction ensured smooth integration with upstream filling and downstream packaging equipment. By adopting this technology, our facility aimed not only to improve operational efficiency but also to meet rigorous hygiene standards mandated in the food and beverage industry.

The results exceeded expectations: labor interventions were reduced, cleaning consistency improved, and the production line achieved a new level of operational predictability. Our experience with the Tianjin ENAK automatic bottle cleaner illustrates how targeted automation can deliver measurable gains in both efficiency and product safety, setting a benchmark for similar facilities seeking scalable solutions.

Customer Requirements

Our primary objectives in selecting a new cleaning system were driven by three interrelated operational needs: efficiency, flexibility, and hygiene. The automatic bottle cleaner had to satisfy these criteria to justify the investment and integrate smoothly into our existing processes.

High-throughput efficiency: Production schedules demanded continuous operation at a pace of 10,000 to 25,000 bottles per hour, depending on product type and bottle size. Manual pre-cleaning and semi-automatic washers were insufficient to handle this volume without introducing delays or compromising cleaning quality. The automatic bottle cleaner needed to maintain consistent throughput even during peak periods, minimizing the risk of bottlenecks while ensuring each bottle received complete cleaning coverage.

Compatibility with multiple bottle types: Our facility handles diverse packaging, including glass, PET, and HDPE bottles ranging from 250ml to 1.5L. Any new system had to accommodate variations in shape, size, and weight without requiring significant downtime or manual adjustments. The automatic bottle cleaner’s design needed to be adaptable, allowing for rapid changeovers between product lines while maintaining uniform cleaning performance.

Automation and reduced labor dependency: Labor shortages and operational costs underscored the importance of a system capable of automated bottle loading and unloading. Manual handling not only slowed production but also increased the risk of contamination and breakage. By automating these steps, the automatic bottle cleaner would reduce labor touchpoints, enhance worker safety, and improve overall production reliability.

Hygiene and regulatory compliance: Regulatory inspections emphasized the importance of thorough internal and external bottle cleaning. Residual contaminants could compromise product safety and result in costly recalls. The automatic bottle cleaner had to ensure consistent application of cleaning agents, high-pressure rinsing, and rapid water drainage, providing full traceability and compliance with industry standards.

In addition, the system needed to be scalable, supporting small-batch specialty beverages as well as high-volume production runs. Modular construction and adjustable parameters were critical for meeting fluctuating demand without requiring complete system replacement. From a customer perspective, these requirements established a clear framework for evaluating performance, reliability, and return on investment in an automated cleaning solution.

Product Features and Application Solutions

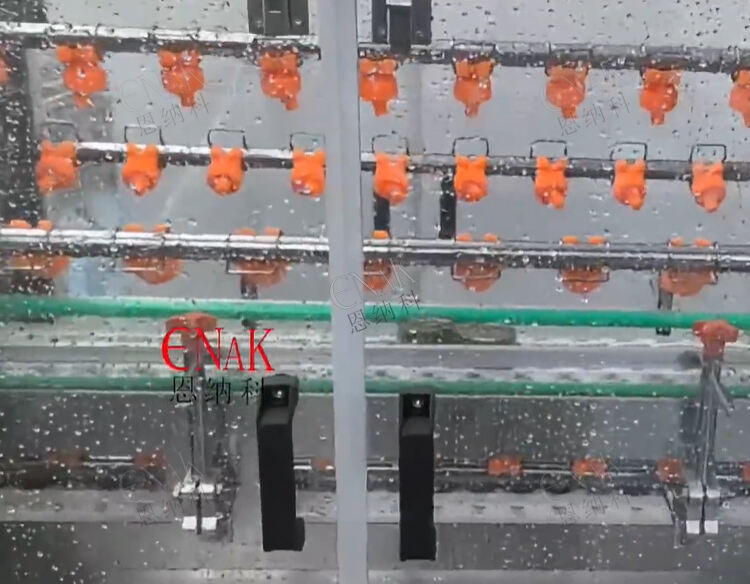

The Tianjin ENAK automatic bottle cleaner addressed our requirements through a combination of advanced technical features and flexible application options.

Automated infeed and outfeed systems: The equipment integrates synchronized conveyors for both loading and unloading bottles. Bottles enter the cleaning chamber in precise orientation, reducing misalignment, tipping, or damage. After cleaning, bottles are automatically discharged to downstream filling or packaging stations. This automation significantly reduces manual handling, allowing operators to focus on quality monitoring and production oversight.

Cleaning speed and bottle compatibility: The system’s multi-station cleaning chambers allow simultaneous washing of hundreds of bottles, each subjected to pressurized jets, heated rinsing, and rotation for thorough internal and external cleaning. Adjustable cycle speeds accommodate different bottle materials and sizes without compromising cleaning effectiveness. For instance, glass bottles are handled gently to minimize breakage, while PET bottles are stabilized to prevent deformation. This versatility ensures production flexibility and supports a wide product range.

High-capacity throughput: The automatic bottle cleaner is capable of processing small to large-scale production volumes, making it suitable for factories with multiple SKUs or variable seasonal demand. High-pressure spray systems combined with rapid water recycling reduce downtime for water changes while maintaining consistent performance. The modular design allows additional cleaning modules to be added when capacity requirements increase.

Application integration: In practice, the automatic bottle cleaner has been seamlessly linked with upstream depalletizers and downstream filling and labeling machines. Sensors monitor bottle flow, ensuring synchronization with the entire production line. By integrating with plant PLC systems, the machine provides real-time feedback on operational status, cycle times, and cleaning effectiveness. This data-driven approach enables predictive maintenance, reducing unplanned downtime and extending equipment life.

Operational results: Since installation, our facility has observed a 40% reduction in labor interventions, a 20% increase in throughput, and a measurable decrease in bottle breakage rates. The automatic bottle cleaner’s consistent performance has improved product safety and reduced rework, directly impacting overall production efficiency and profitability.

Additional benefits: Stainless steel construction ensures durability and hygiene compliance, while energy-efficient motors and water-recycling features minimize operational costs. The system’s modularity also allows rapid adaptation for new bottle types or packaging formats, future-proofing our investment in automation.

Conclusion

From the perspective of a customer representative, the implementation of the Tianjin ENAK automatic bottle cleaner has transformed our production line’s efficiency and reliability. Automation of bottle infeed and outfeed reduces manual handling, minimizes breakage, and ensures steady throughput across diverse product types. High-speed, adaptable cleaning cycles support both glass and PET bottles, providing consistent quality without compromising production flexibility.

The automatic bottle cleaner’s modular design allows the system to scale with production growth, while its integration with existing PLC systems provides real-time operational feedback. This capability enhances predictive maintenance, reduces unplanned downtime, and maximizes overall equipment effectiveness. As a result, our facility has experienced tangible improvements in productivity, product safety, and operational resilience.

Beyond technical performance, the system has strategic benefits: labor efficiency is improved, compliance with hygiene standards is consistently met, and the flexibility to accommodate multiple bottle types enhances market responsiveness. By adopting the automatic bottle cleaner, our production line has moved closer to full automation, positioning the company for long-term growth and competitiveness in the beverage industry.

In summary, the Tianjin ENAK automatic bottle cleaner is not just a cleaning machine—it is a comprehensive production solution. For companies seeking high-throughput, flexible, and reliable bottle cleaning, it delivers measurable operational advantages, demonstrating the value of integrating advanced automation into modern production lines. The system exemplifies how targeted technological investment can drive efficiency, safety, and profitability in beverage manufacturing.